Flexible waterproof slurry

A kind of waterproof slurry, flexible technology, applied in the field of construction slurry, can solve the problems of not optimal value of water-cement ratio, not optimal value of sand content ratio, low flexibility strength, etc., to improve bonding strength and Anti-osmotic pressure, safe and stable active ingredients, and improved toughness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

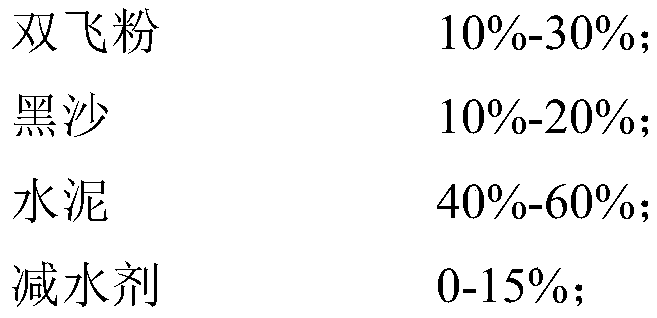

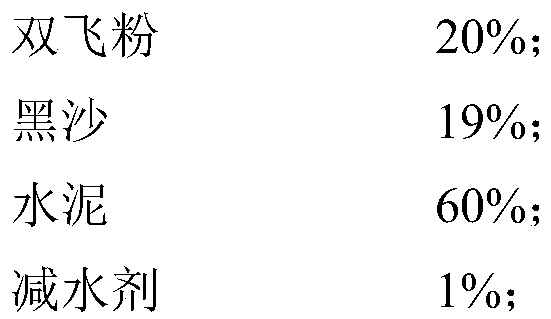

[0029] A kind of flexible waterproof slurry, including powder and liquid, wherein the powder contains the following components in mass percentage: 200 mesh Shuangfei powder 20%; 70-140 mesh black sand 19%; Conch 525 gray cement 60%; Maidi -100 water reducer 1%;

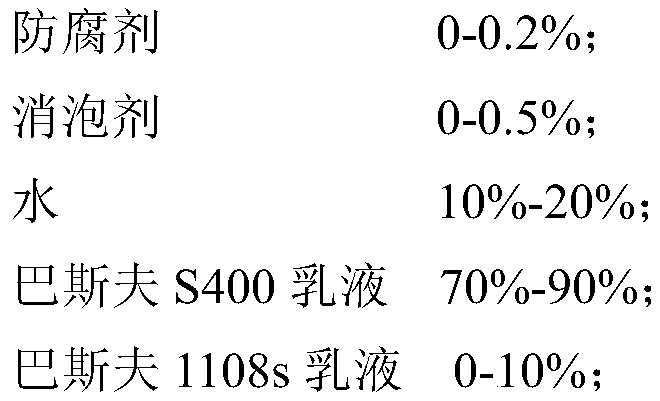

[0030] Liquid formulation comprises the component that following mass percent is arranged: preservative (selecting the model provided by Huanqi Chemical Co., Ltd. is Troy K9N bactericide, certainly also can select other bactericidal preservatives) 0.15%; Defoamer (selects Shenzhen Haichuan new material NXZ mineral oil defoamer produced by Technology Co., Ltd., of course, other defoamers can also be used) 0.4%; water 14.45%; BASF S400 emulsion 80%; BASF 1108s emulsion 5%.

[0031] When in use, mix and stir the components of the powder formulation, mix and stir the components of the liquid formulation, and then mix the powder formulation and the liquid formulation uniformly at a mass ratio of 1:0.68 to obtain a waterpro...

Embodiment 2

[0039] A flexible waterproof slurry, including powder and liquid, wherein the powder includes the following components in mass percentage: 200 mesh Shuangfei powder 15%; 70-140 mesh black sand 20%; Conch 525 gray cement 50%; Maidi -100 water reducing agent 15%;

[0040] Liquid formulation comprises the component that following mass percent is arranged: preservative (selecting the model provided by Huanqi Chemical Co., Ltd. is Troy K9N fungicide) 0.2%; foam agent) 0.5%; water 10%; BASF S400 emulsion 89.3%.

[0041] When in use, mix and stir the components of the powder formulation, mix and stir the components of the liquid formulation, and then mix the powder formulation and the liquid formulation uniformly at a mass ratio of 1:0.6 to obtain a waterproof slurry.

[0042] The product prepared in this embodiment is tested and found to have high elasticity, waterproof and impermeability, acid and alkali resistance, aging resistance, not easy to crack, and stability greater than 1...

Embodiment 3

[0044] A flexible waterproof slurry, including powder and liquid, wherein the powder includes the following components in mass percentage: 200 mesh Shuangfei powder 30%; 70-140 mesh black sand 20%; Conch 525 gray cement 40%; Maidi -100 water reducing agent 10%;

[0045] The liquid preparation includes the following components in mass percentage: 20% of water; 70% of BASF S400 emulsion; 10% of BASF 1108s emulsion.

[0046] When in use, mix and stir the components of the powder formulation, mix and stir the components of the liquid formulation, and then mix the powder formulation and the liquid formulation uniformly at a mass ratio of 1:0.68 to obtain a waterproof slurry.

[0047] The product prepared in this embodiment is tested and found to have high elasticity, waterproof and impermeability, acid and alkali resistance, aging resistance, not easy to crack, and stability greater than 12 months.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com