Ozone catalytic oxidation reactor and sewage treatment method thereof

An ozone catalytic oxidation and reactor technology, which is applied in the directions of oxidized water/sewage treatment, water/sewage treatment, chemical instruments and methods, etc., can solve the problem of poor cleaning effect of suspended solids, large amount of backwashing water, and affecting the reaction efficiency of sewage treatment. Catalyst service life and other issues, to achieve the effect of saving backwash water consumption, efficient backwashing, and small equipment footprint

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

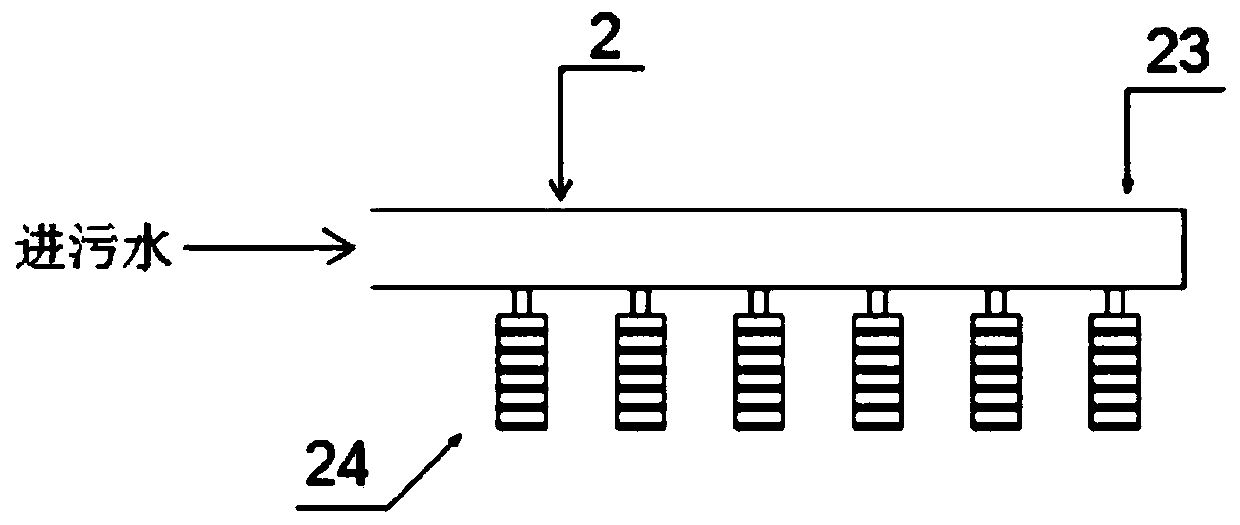

[0054] Such as figure 1 As shown, it is an ozone catalytic oxidation reactor, including a reactor body 1, and a sewage distributor 2, a sand filter layer 3, and a catalyst layer 4 are sequentially arranged in the reactor body 1 from top to bottom, and the catalyst layer 4 The lower side is also provided with an ozone aeration pan 5 and a backwash water inlet distributor 6; the sand filter layer 3 is provided with a backwash gas distributor 7; 30, for monitoring the resistance of the sand filter layer 3 (that is, the pressure difference);

[0055] The sewage distributor 2 is connected to a sewage water inlet pipe, and a sewage valve 20 and a sewage flow meter 21 are sequentially arranged on the sewage water inlet pipe along the water inlet direction, and a drainage pipe with a drainage valve 22 is also arranged at the bottom of the reactor body 1; The ozone aeration pan 5 is connected to the ozone generator 50 through an ozone pipeline, and an ozone tube valve 51 and an ozone ...

Embodiment 2

[0067] combine Figure 1~2 As shown, the present embodiment is a sewage treatment method of an ozone catalytic oxidation reactor, comprising the following treatment steps:

[0068] S1. The sewage to be treated is sent to the top of the reactor body 1, and evenly enters the reactor body 1 through the sewage distributor 2. The sewage is first filtered through the sand filter layer 12, and the suspended solids contained in the sewage are filtered and removed. The solid content of the final sewage is less than 10mg / l; the sewage continues to flow down to the catalyst layer 4, and is countercurrently mixed with the ozone gas flow flowing from the bottom of the reactor body 1 to the catalyst layer 4, and the ozone generates hydroxyl radicals under the action of the catalyst. Degrade the organic matter in the sewage, and the treated sewage is discharged from the drainage pipe at the bottom;

[0069] S2. As the running time increases, the suspended matter trapped in the sand filter l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com