A device and method for preparing carbon airgel by CVD after arc activation of carbon nanotubes

A technology of carbon airgel and carbon nanotubes, applied in chemical instruments and methods, aerosol preparation, carbon compounds, etc., can solve the problems of unfavorable cost control and scale-up production, and achieve simple structure, low bulk density and stable method easy to control effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

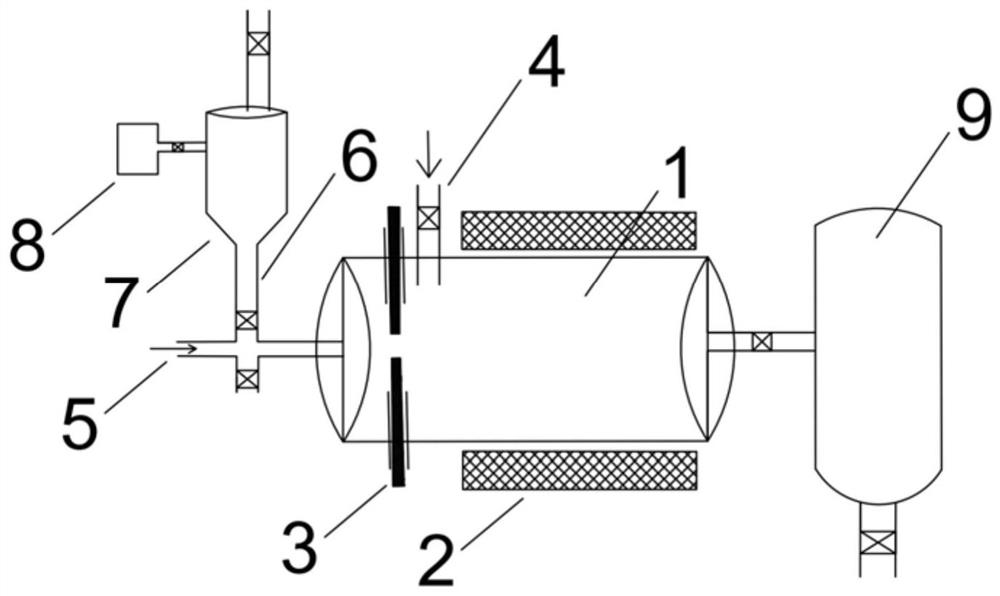

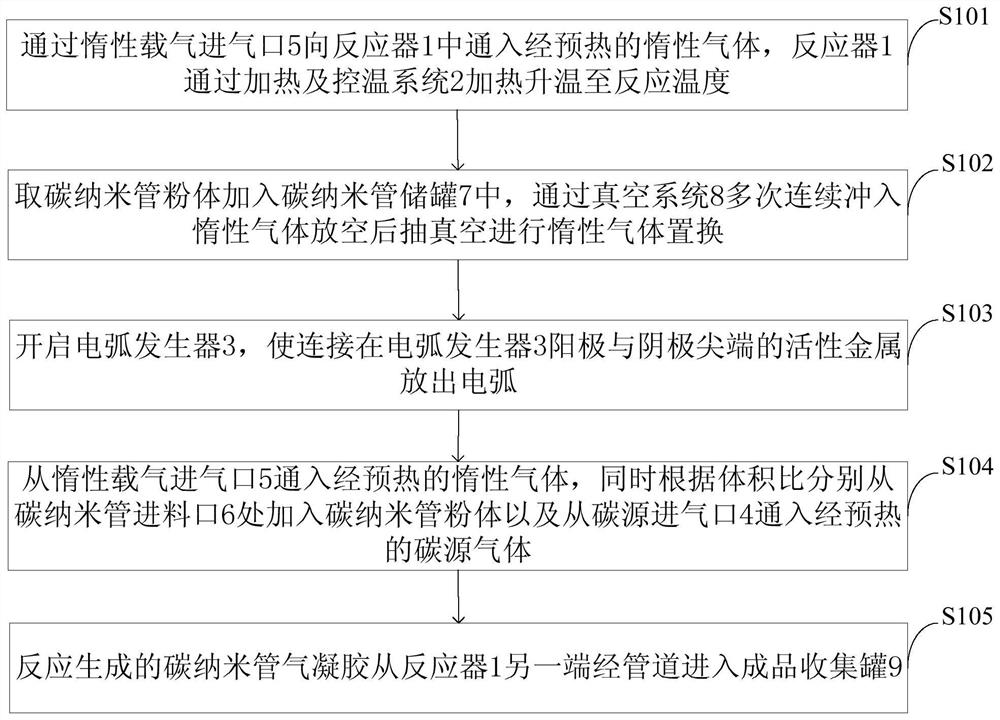

[0060] (1) Pass nitrogen preheated at 800°C from 5 to 1-reactor, and turn on equipment 2 to heat up to 790°C-800°C;

[0061] (2) 900g vertical array carbon nanotube powder is added in the 7-carbon nanotube storage tank, and the nitrogen gas is continuously flushed through 8 for three times and then evacuated for inert gas replacement;

[0062] (3) Turn on the DC arc generating device of 1800W power, so that the tip of the 3-connected iron element emits an electric arc;

[0063] (4) adjust the nitrogen of 3L / min into the 5 inlet, add 5g / min carbon nanotube powder from the 6-carbon nanotube feed inlet and feed 1L / min from the 4-carbon source inlet respectively min Carbon monoxide gas preheated at 750°C;

[0064] (5) the carbon nanotube airgel that generates enters 9 finished product collection tanks through pipeline from the other end of the reactor;

[0065] (6) keeping the reaction for 90min in this way, and continuously preparing high-performance carbon nanotube airgel;

...

Embodiment 2

[0068] (1) Pass the argon gas preheated at 920°C from 5 to the 1-reactor, and turn on the equipment 2 to heat up to 910°C-920°C;

[0069] (2) Add 2000g of vertically arrayed carbon nanotube powder into the 7-carbon nanotube storage tank, carry out five consecutive flushes of argon through 8 and then vacuumize to complete the replacement;

[0070] (3) Open the alternating current arc generating device of 2000W power, make 3-connect the tip of simple nickel to discharge electric arc;

[0071] (4) Adjust the argon of 20L / min into the 5 inlet, and add 12g / min carbon nanotube powder from the 6-carbon nanotube feed inlet and feed 5L from the 4-carbon source inlet respectively. / min methane gas preheated at 880°C;

[0072] (5) the carbon nanotube airgel that generates enters 9 finished product collection tanks through pipeline from the other end of the reactor;

[0073] (6) keeping the reaction for 120min in this way, and continuously preparing high-performance carbon nanotube airg...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com