Blade spring composite cover plate

A leaf spring and cover plate technology, which is applied in the direction of springs, springs/shock absorbers, leaf springs, etc., can solve the problems of heavy leaf spring cover plate, damage to leaf springs and fastening bolts, and unsuitable development requirements for lightweight vehicles and other issues, to achieve the effect of cushioning and dispersing loads, eliminating costs, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention is described in detail below in conjunction with accompanying drawing and specific embodiment:

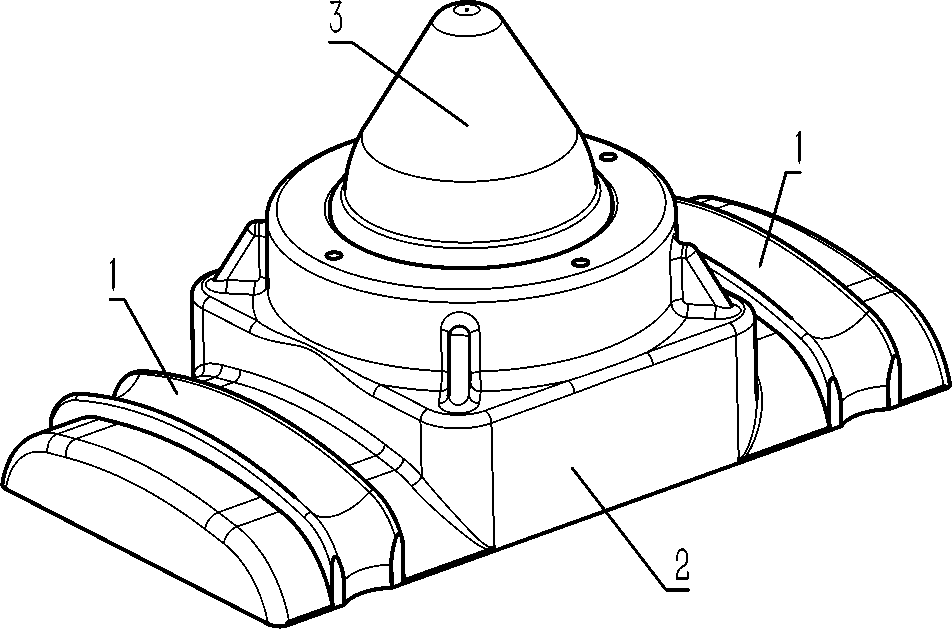

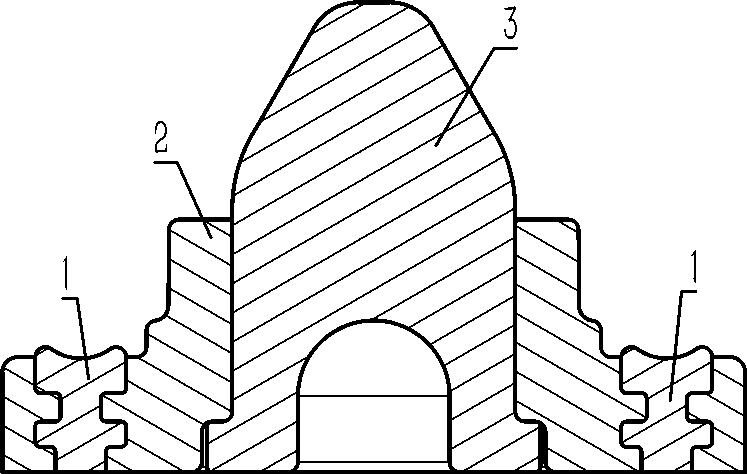

[0026] An example of the present invention Figures 1 to 4 As shown, a leaf spring composite cover plate includes a skeleton 1, the upper end surface of the skeleton 1 fits with the inner curved section of the U-bolt 11, the skeleton 1 is arranged in a matrix 2 made of fiber reinforced polymer material, and the skeleton 1 is made of metal , the lower end surface of the skeleton 1 is flush with the lower end surface of the base body 2 , and the upper end face of the skeleton 1 is exposed on the surface of the base body 2 . There are two skeletons 1 in total, and the two skeletons 1 are independent metal parts and are arranged in the same base body 2 . The base body 2 is provided with a buffer block installation hole, the buffer block 3 is installed in the installation hole, the lower end is flush with the lower end surface of the base body 2 , and the u...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com