On-line cutting and stacking device for manufacturing prefabricated plates from industrial solid wastes

A palletizing device and industrial solid waste technology, applied in the direction of manufacturing tools, object stacking, transportation and packaging, etc., can solve problems such as difficulties in off-line palletizing of plates, reduce safety hazards, ensure continuous production, and reduce labor The effect of intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

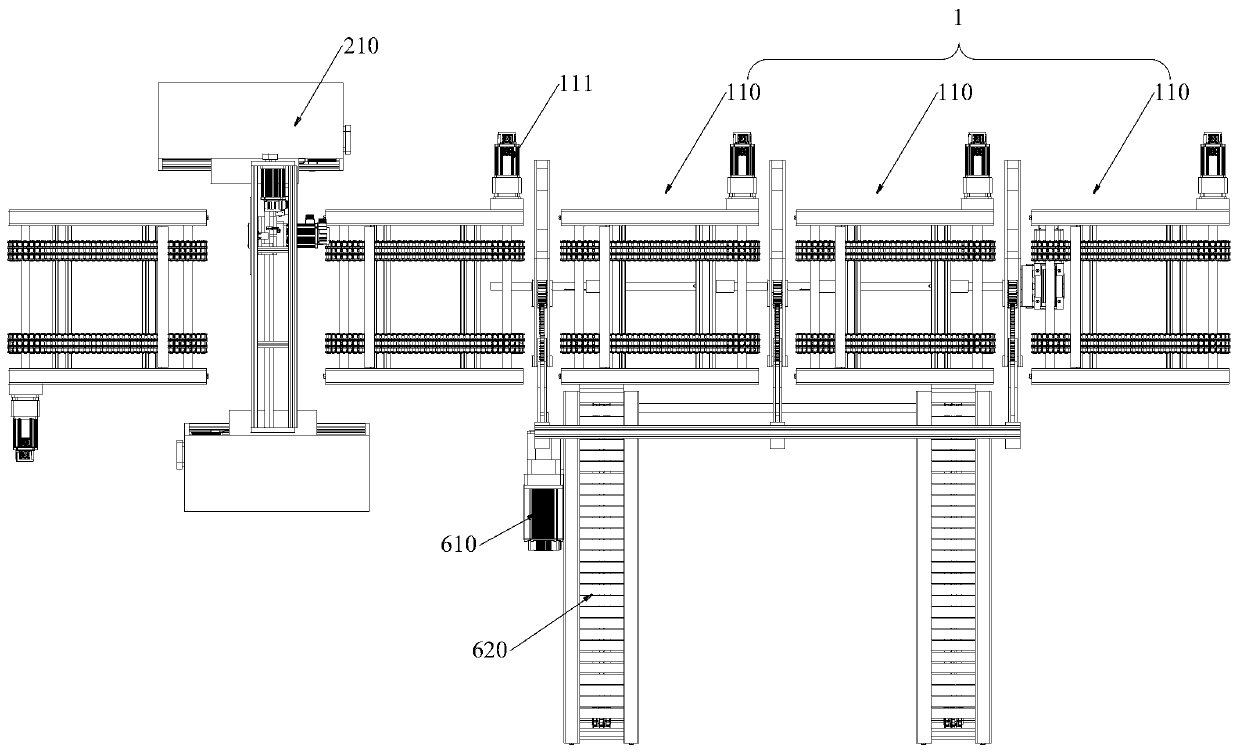

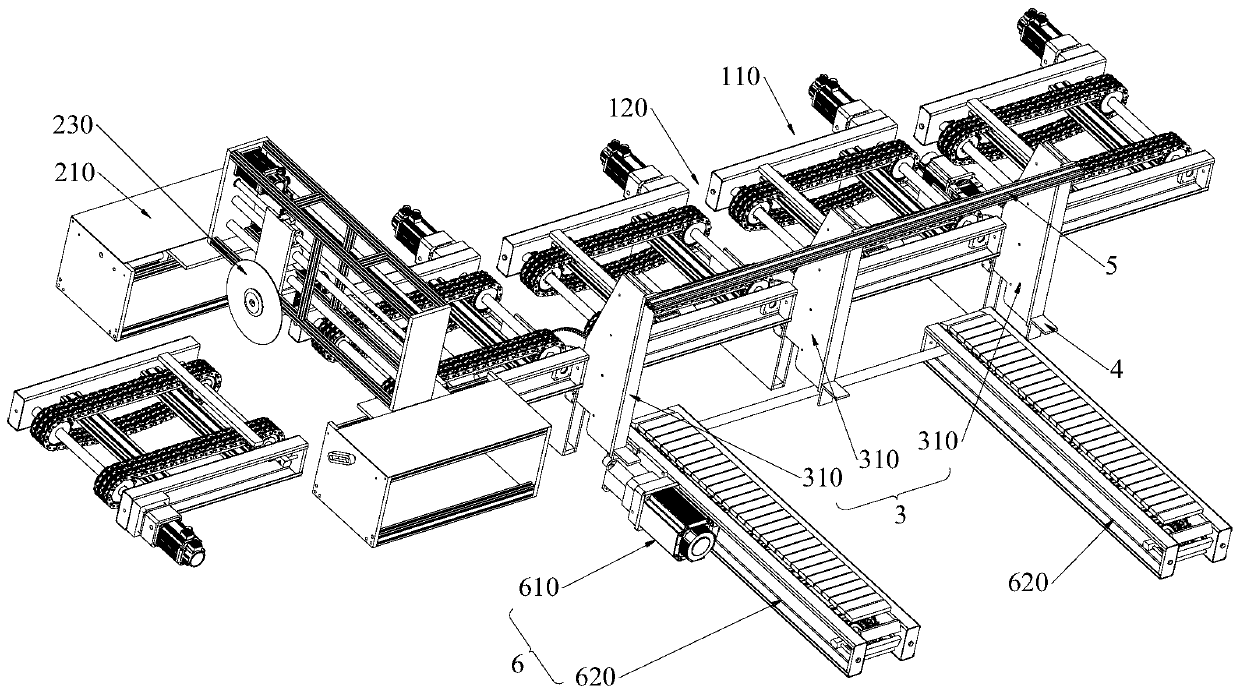

[0030]The online cutting and palletizing device 6 for preparing prefabricated boards from industrial solid waste of the present invention includes a conveying device 1, and the conveying device 1 includes a plurality of conveying units 110, and gaps 120 are provided between adjacent conveying units 110, and above any gap 120 A cutting device 2 is provided, and a turning device 3 is arranged at the rear end of the cutting device 2 along the material conveying direction. The turning device 3 includes a plurality of turning units 310 which rotate synchronously. The plate 314, the middle tooth 313, the power tooth 312 and the turning shaft seat 311, the turning shaft seat 311 is located below the gap 120 of the adjacent conveying unit 110, and the fan tooth plate 314 is connected to one side of the turning shaft seat 311 by rotating in the vertical direction. The middle tooth 313 is rotationally connected with the turning shaft seat 311, one side of the middle tooth 313 meshes with...

Embodiment 2

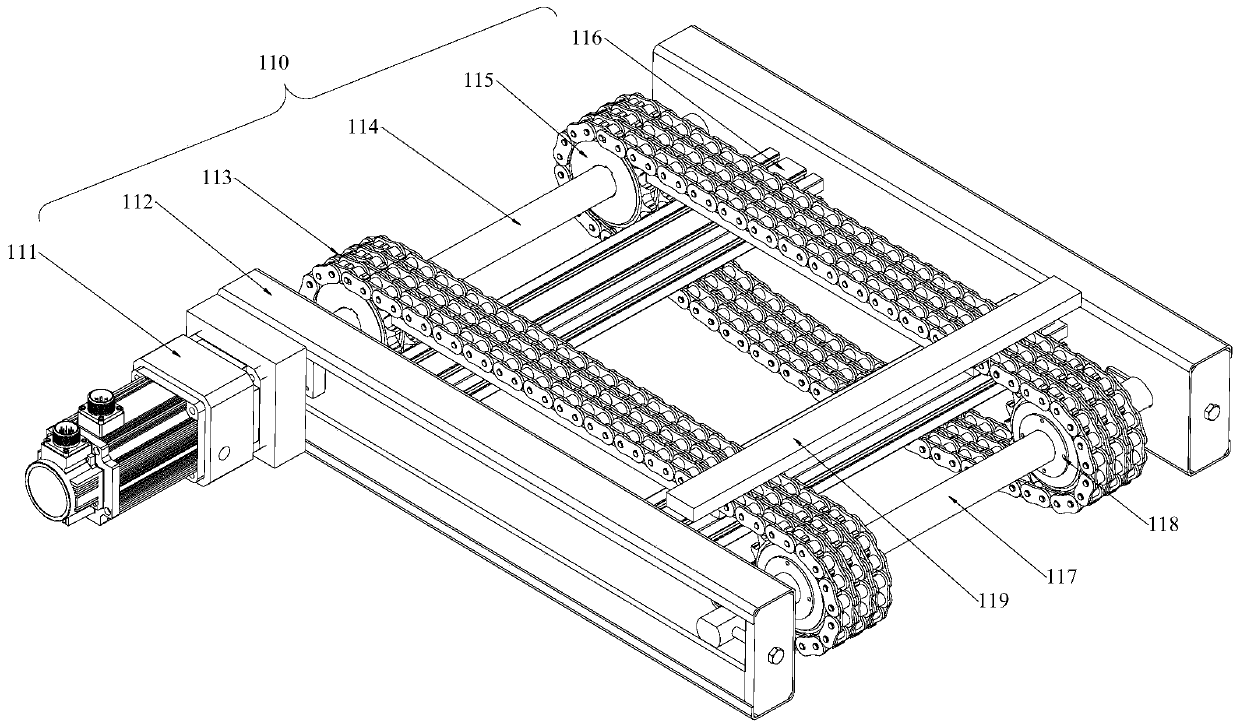

[0033] This embodiment is further optimized on the basis of Embodiment 1 as follows: the conveying unit 110 includes a side guard plate 112, a support plate 116, a conveying crawler belt 113, a driving shaft 114, a driving tooth 115, a driven shaft 117, and a driven tooth 118 and conveying motor 111; the left and right sides of the support plate are respectively connected with side guards 112, the driving shaft 114 and the driven shaft 117 are respectively rotated and connected between the two side guards 112, and the driving shaft 114 runs through one side of the side guard After the plate 112 is connected with the conveying motor 111, a driving tooth 115 is sleeved on the driving shaft 114, a plurality of driven teeth 118 are sleeved on the driven shaft 117, and the conveyor belt 113 passes through the driving gear 115 and the driven gear 118 It is sleeved on the periphery of the driving shaft 114 and the driven shaft 117 .

[0034] After adopting the above-mentioned technic...

Embodiment 3

[0036] This embodiment is further optimized on the basis of Embodiment 1 as follows: As a further preference of the present invention, the cutting device 2 includes an X-axis module 210 located above the conveying device 1 and an X-axis module 210 located below the two ends of the X-axis module 210. Y-axis module 220. The X-axis module 210 includes a beam frame 211, a transverse guide rail 212, a transverse slide 215, a transverse screw 217, a transverse motor 216, a cutting knife 213, and a cutting motor 214; the two ends of the transverse guide rail 212 are arranged on the beam frame 211 to cut off the motor 214 and the cutting knife 213 are connected to each other, the cutting knife 213 and the cutting motor 214 are connected as a whole through the horizontal sliding seat 215 and the horizontal guide rail 212, and the horizontal screw 217 runs through the horizontal sliding seat 215 and is connected to the horizontal motor 216; 220 includes a longitudinal beam frame 221, a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com