Sawing numerical-control equipment used for right-angled circular-arc chamfering in board

A technology of arc chamfering and numerical control equipment, applied in the field of sheet metal processing, can solve the problems that the processing quality and processing efficiency cannot meet the mass production of customized furniture, increase the production and sales cost of customized furniture enterprises, and affect the consumption experience of users. The effect of avoiding sheet skin damage, maintaining synchronization and continuity, and improving processing efficiency and processing accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

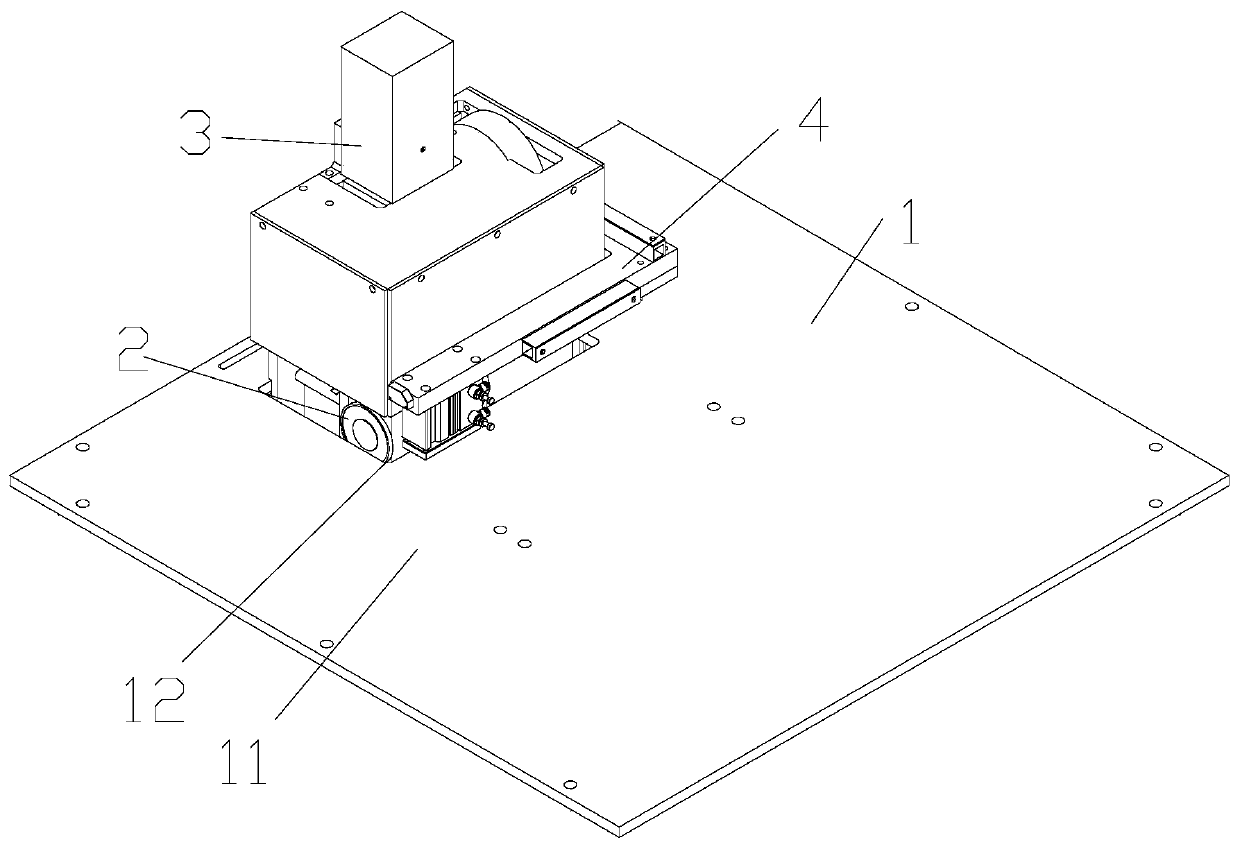

[0042] This embodiment is a kind of sawing numerical control equipment used for right-angle arc chamfering in plates, and its structure is as follows Figure 1 to Figure 4 As shown, the right-angled arc chamfering of the plate that needs to be sawed is as follows Figure 5 Shown; sawing CNC equipment includes:

[0043] Rack 1;

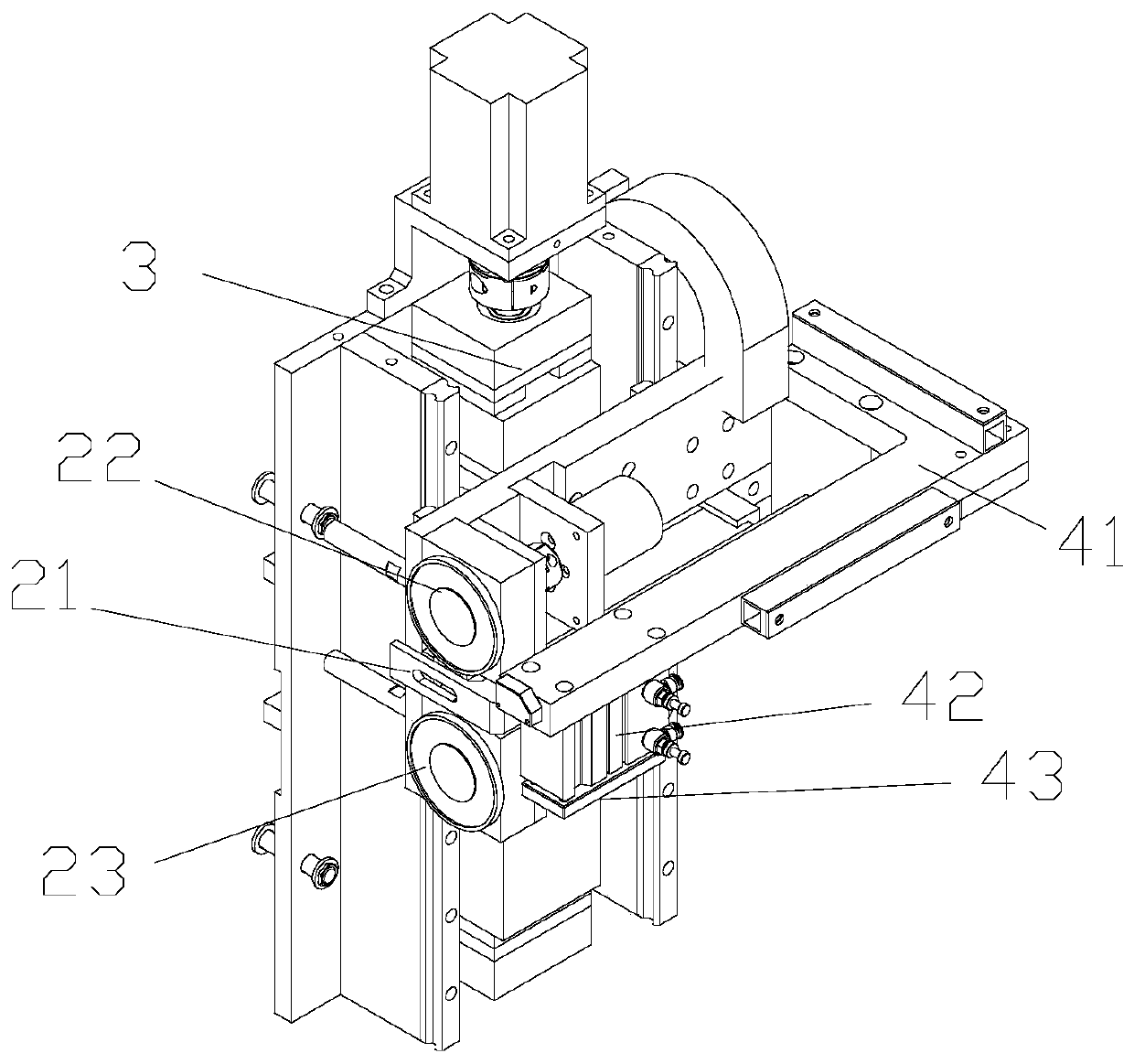

[0044] Saw mechanism 2 for plate positioning and sawing processing;

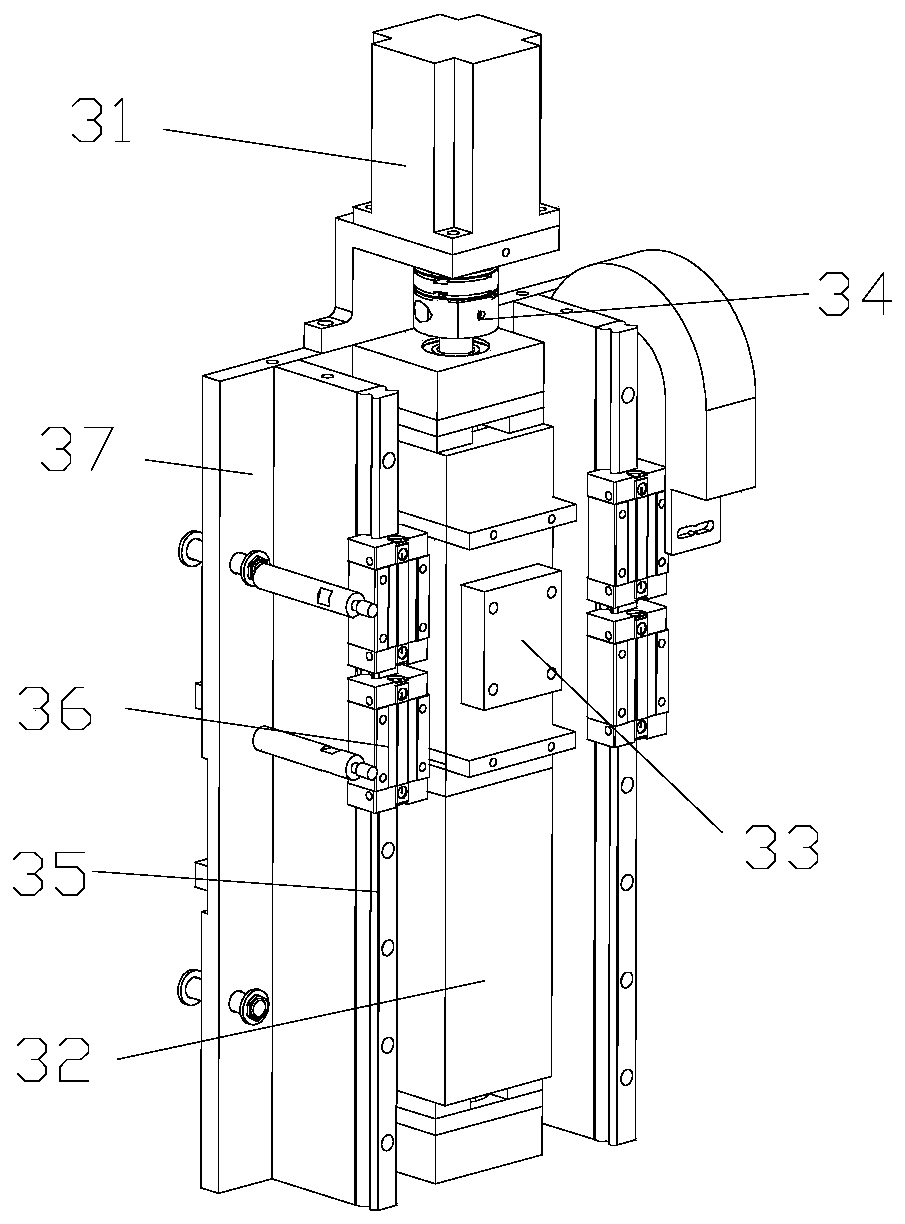

[0045] A z-axis mechanism 3 for driving the sawing mechanism 2 to reciprocate along the z-axis;

[0046] And a pressing plate mechanism 4 for pressing and fixing the plate.

[0047] The frame 1 is provided with a support platform 11 for supporting plates; the support platform 11 preferably has a corner position 12 . The support platform 11 has a corner position 12 to better support and position the plates.

[0048] The pressing plate mechanism 4 is located above the supporting platform 11 . The pressing plate mechanism 4 includes a supporting frame 41 arranged on the frame 1 , ...

Embodiment 2

[0062] This embodiment is a kind of sawing numerical control equipment used for right-angled arc chamfering in plates. The difference from Embodiment 1 is that in this embodiment, the positioning structure does not use a right-angle stopper, but other existing methods; the positioning structure Whether it is set on the saw mounting plate or not, it only needs not to block the movement of the upper saw assembly and the lower saw assembly. The rest of the structure of this embodiment is the same as that of Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com