Rotary moving workbench

A technology for moving workbenches and workbench bases, applied to workbenches, manufacturing tools, metal processing equipment, etc., can solve problems such as complex mechanical connection devices, complex control circuits, and low transmission efficiency, and improve positioning accuracy and response speed , fast response, short transmission line

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

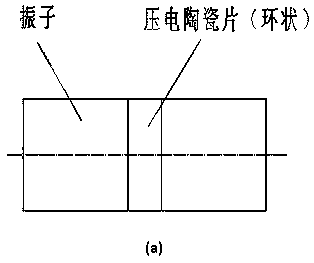

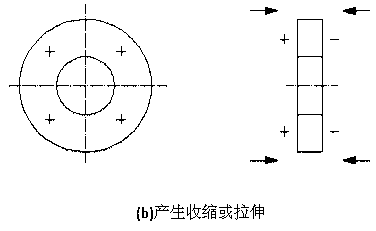

[0024] The following is a detailed description in conjunction with the accompanying drawings: As shown in the figure, in order to facilitate the description of the working principle, the driving device is simplified, and the ring-shaped driving foot is simplified into a single tooth shape, such as figure 1 As shown, when the piezoelectric ceramic group A passes through a periodic alternating electrical signal, the vibrator forms a second-order bending vibration mode, and the driving foot contacts the vibrator to exert pressure on the vibrator. When the piezoelectric ceramic group B is energized, the vibrator forms a torsional mode At this time, the bending and torsion are compounded, and under the action of friction, the mover can be freely driven to move back and forth.

[0025] The support seat 19 is fixed on the workbench base 1 by the set screw B24, the clutch device 15 is fixed on the support seat 19 by the positioning disc 23 and the positioning bolt B20, the clutch devic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com