Eutectic brazing fixture and eutectic brazing process for MCM

A brazing process and brazing technology, applied in the field of multi-chip module packaging, can solve the problems of difficult to achieve heat dissipation and microwave grounding effect, small process window, cumbersome process, etc., achieve difficult thickness control, avoid melt overflow, low surface The effect of tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

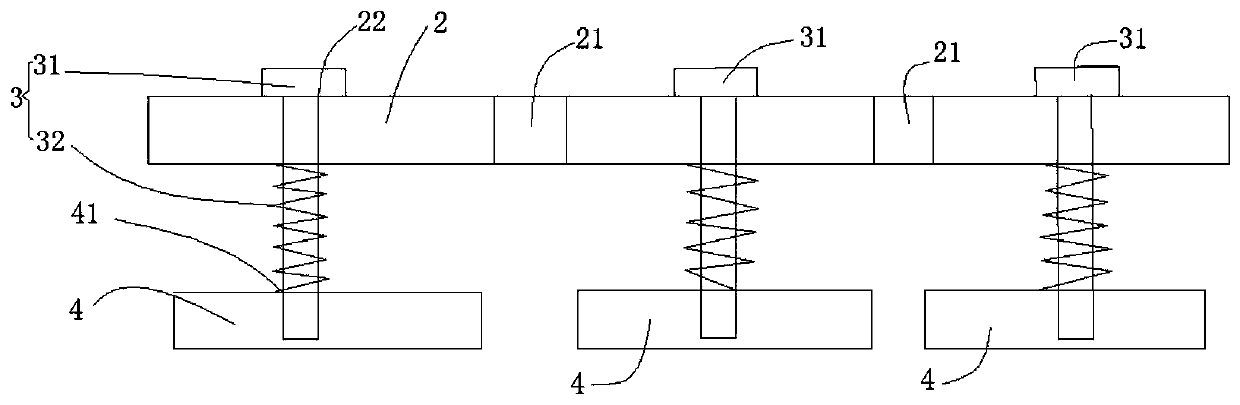

[0036] like figure 2 and image 3 As shown, this embodiment provides a kind of MCM eutectic brazing tooling, which is used to respectively apply uniform pressure, including a cover plate 2 at the mouth of the box body 11, and the side of the cover plate 2 close to the inside of the box is provided with a plurality of adjustment parts 3 parallel to the cover plate 2 Press block 4, and each of the adjustment parts 3 runs through the cover plate 2, and each microstrip 13, LTCC substrate 14 and copper-clad dielectric board 15 correspond to one press block 4, each of the The pressure block 4 adjusts the pressure applied to the corresponding microstrip sheet 13, LTCC substrate 14 or copper-clad dielectric board 15 through the corresponding adjustment member 3, and the cover plate 2 corresponds to the box body 11 The exposed upper end of the inner AlSiC carrier plate 12 is provided with a brazing hole 21 passing through it. Its structure is simple, and uniform and controllable pr...

Embodiment 2

[0049] like Figure 4 As shown, the present embodiment provides a MCM eutectic brazing process, which includes the following steps in sequence,

[0050] Step a: Take the box body 11, LTCC substrate 14, copper-clad dielectric board 15, AlSiC carrier board 12 and microstrip sheet 13 respectively according to the product structure, and place the LTCC substrate 14, copper-clad dielectric board 15, AlSiC carrier board 12 and microstrip The tape 13 is preset in the box body 11 according to the product structure, and the microstrip sheet 13 is electrically connected to the corresponding pins on the box body 11, and at the same time, between the AlSiC carrier board 12 and the inner bottom wall of the box body 11 Preset the first solder piece 16 between them, and preset the second solder piece 17 between the AlSiC carrier board 12 and each of the LTCC substrates 14, copper-clad dielectric board 15 and microstrip sheet 13;

[0051] Step b: Place the cover plate 2 horizontally at the bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com