Niobic acid-based sulfide composite material and preparation method thereof

A composite material and sulfide technology, applied in chemical instruments and methods, chemical/physical processes, special compound water treatment, etc. The effect of reducing the difficulty of synthesis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

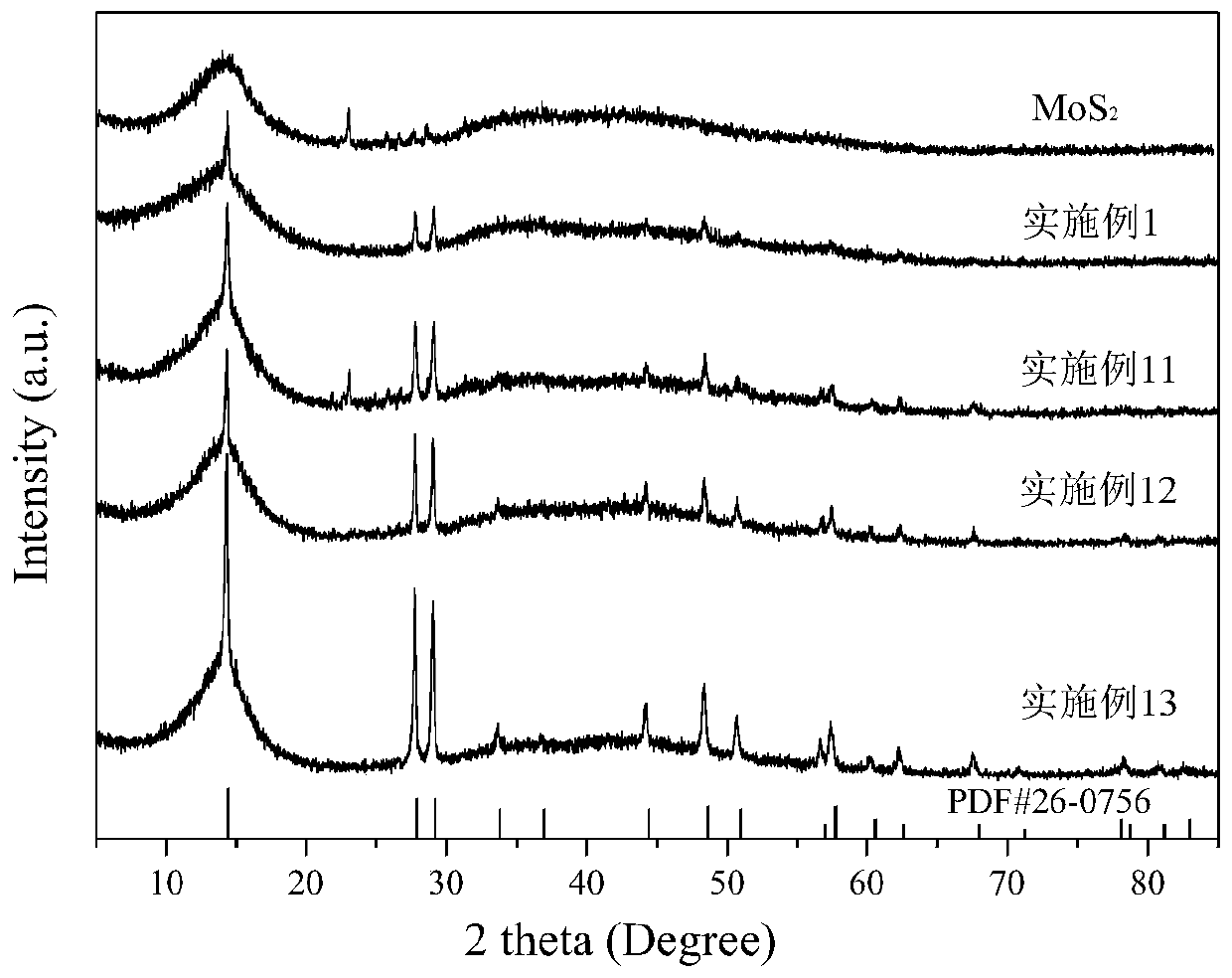

[0026] MoS 2 -H 4 Nb 2 o 7 preparation of

[0027] 1) Weigh 0.1g of tin niobate and add it to the PTFE lining, add 1.84g of ammonium molybdate and 2.4g of thiourea, add 30mL of 0.12mol / L hydrochloric acid solution to adjust the pH to 0.9, and put it into the kettle , reacted at 160°C for 12h to obtain a black precipitate;

[0028] 2) The black precipitate obtained after the reaction in 1) was filtered and washed, and dried in a vacuum oven at 60°C for 6 hours to obtain MoS 2 -H 4 Nb 2 o 7 composite material.

Embodiment 2

[0030] CoS 2 -H 4 Nb 2 o 7 preparation of

[0031] 1) Weigh 0.2g of tin niobate and add it to the PTFE lining, add 2.9g of cobalt nitrate hexahydrate and 2.4g of thiourea, add 60mL of 0.12mol / L hydrochloric acid solution to adjust the pH to 0.9, and put it into the kettle In the reaction at 200°C for 2 hours, a black precipitate was obtained;

[0032] 2) The black precipitate obtained after the reaction in 1) was filtered and washed, and dried in a vacuum oven at 60°C for 6 hours to obtain CoS 2 -H 4 Nb 2 o 7 composite material.

Embodiment 3

[0034] FeS 2 -H 4 Nb 2 o 7 preparation of

[0035] 1) Weigh 0.15g tin niobate and add it to the polytetrafluoroethylene lining, add 2.8g ferrous sulfate and 1.2 thiourea, add 0.12mol / L hydrochloric acid solution 45mL to adjust the pH to 0.9, put it into the kettle, React at 200°C for 12 hours to obtain a black precipitate;

[0036] 2) The black precipitate obtained after the reaction in 1) was filtered and washed, and dried in a vacuum oven at 60°C for 6 hours to obtain FeS 2 -H 4 Nb 2 o 7 composite material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com