Bag type dust remover monitoring and diagnosis analysis system

A bag filter, diagnostic analysis technology, applied in the analysis of materials, permeability/surface area analysis, suspension and porous material analysis, etc., can solve the problem that the diagnostic function of the pulse valve cannot be realized, the leakage of the pulse valve cannot be judged, and it is easy to cause tinnitus. and other problems, to achieve the effect of simple structure, reduced manpower, and increased detection range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

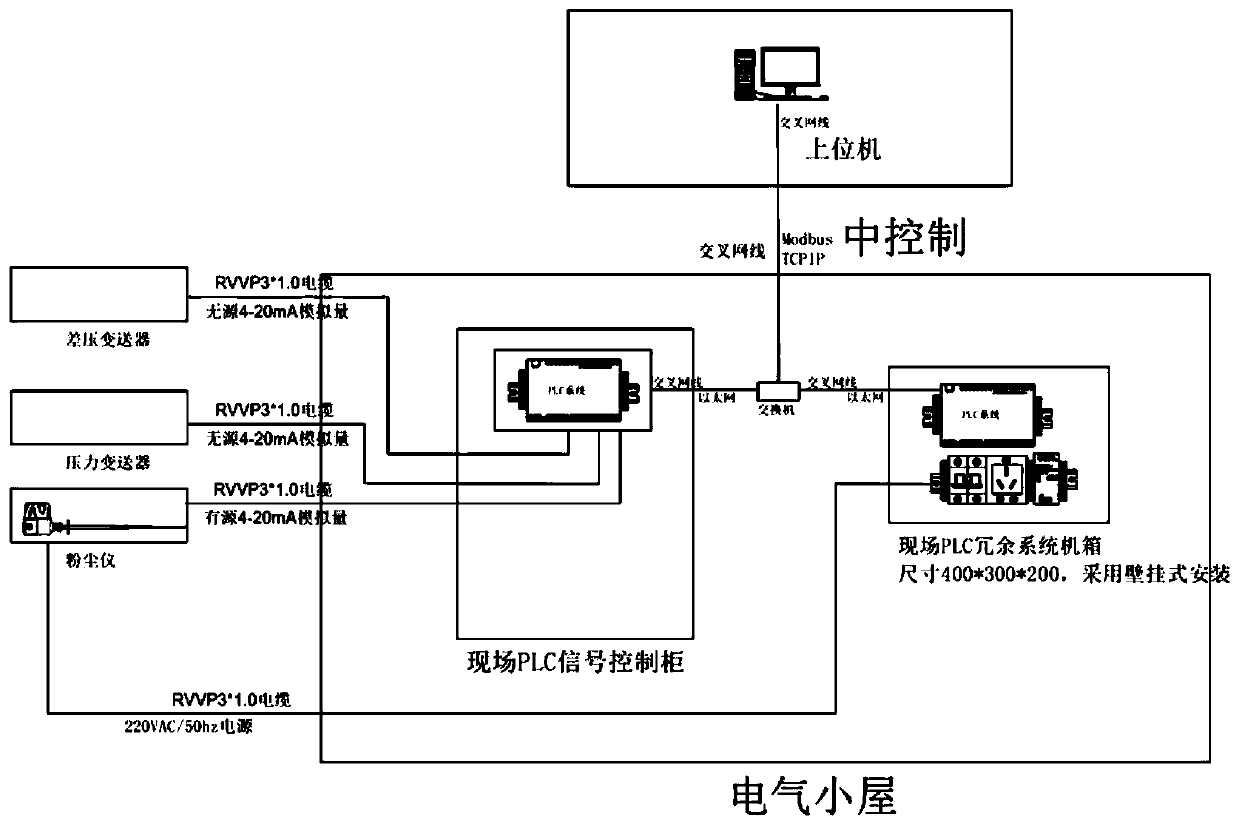

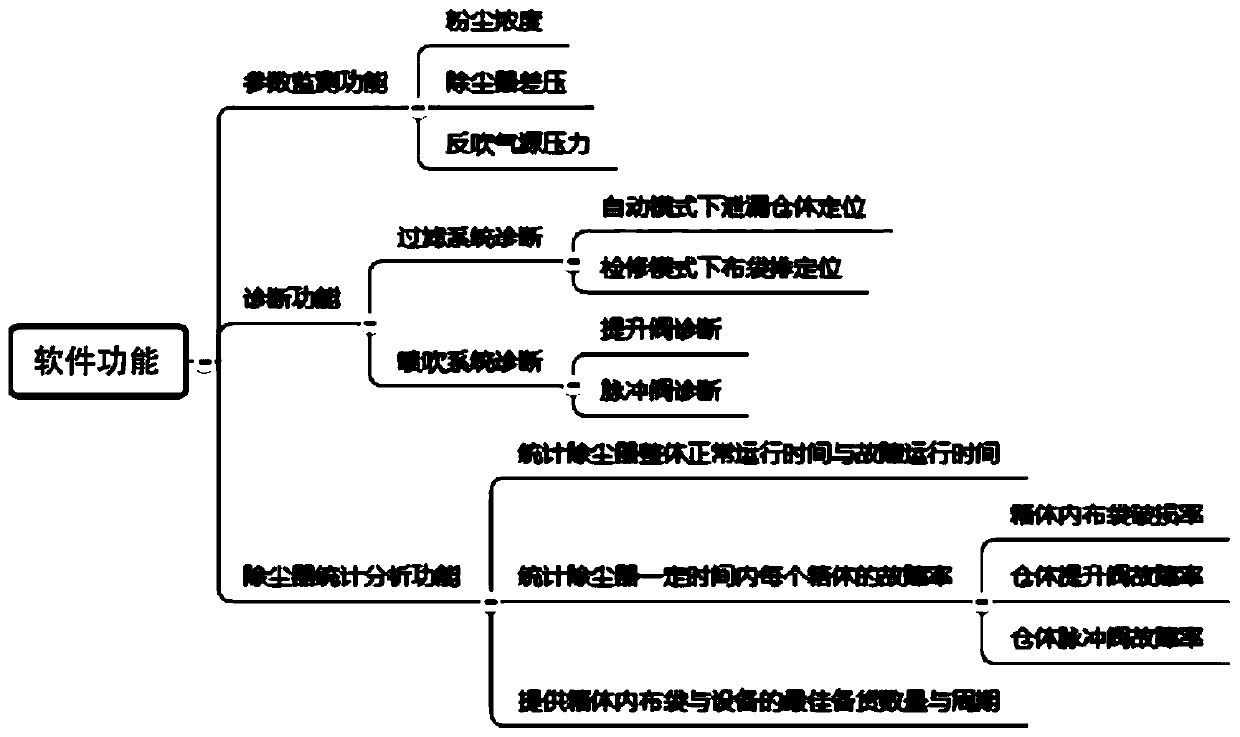

[0068] 1. System composition:

[0069] 1.1 The dust collector monitoring hardware is: a double-probe high-precision dust meter; a single crystal silicon differential pressure transmitter; two single crystal silicon pressure transmitters.

[0070] 1.2 Data acquisition equipment: data acquisition cabinet, including PLC and switching power supply.

[0071] 1.3 Host computer: PC mainframe (such as industrial computer); PC mainframe is equipped with dust collector online monitoring and diagnosis software.

[0072] 2. System installation:

[0073] 2.1 Dust collector end: The double-probe high-precision dust meter is installed at the outlet pipe of the dust collector, the pressure point of the monocrystalline silicon differential pressure transmitter is installed at the inlet and outlet of the dust collector, and the monocrystalline silicon pressure transmitter is installed at the gas storage Tank outlet header.

[0074] 2.2 Data acquisition cabinet: The data acquisition cabinet a...

specific approach 2

[0083] 1. System composition:

[0084] 1.1 The monitoring hardware of the dust collector is: one double-probe high-precision dust meter; thirty-two dust concentration meters; one single crystal silicon differential pressure transmitter; two single crystal silicon pressure transmitters.

[0085] 1.2 Data acquisition equipment: data acquisition cabinet, including PLC and switching power supply.

[0086] 1.3 Host computer: PC mainframe (such as industrial computer); PC mainframe is equipped with dust collector online monitoring and diagnosis software.

[0087] 2. System installation:

[0088] 2.1 Dust collector end: The double-probe high-precision dust meter is installed at the outlet pipe of the dust collector, 32 dust concentration meters are installed on each bin of the dust collector, and the pressure point of the monocrystalline silicon differential pressure transmitter is installed on the dust collector The inlet and outlet of the single crystal silicon pressure transmitt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com