Microneedle array dry electrode based on flexible substrate and preparation method of microneedle array dry electrode

A microneedle array and flexible substrate technology, applied in the field of medical devices, can solve the problems of not being able to penetrate the skin well, not being able to fit the human skin well, and low strength, and achieve good safety, low cost, and high strength Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] refer to Figure 9 , the method for preparing a metal microneedle array dry electrode based on a flexible substrate in this embodiment includes the following steps:

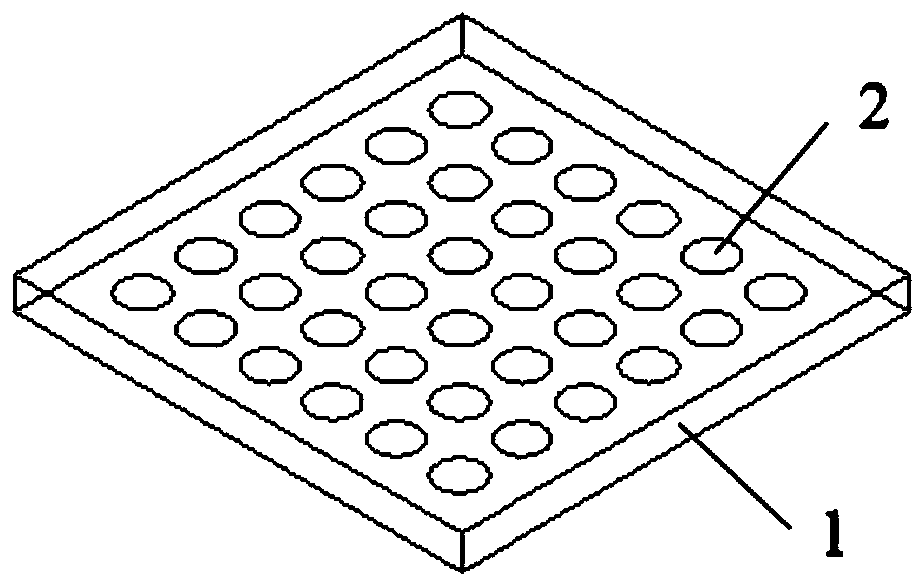

[0033] (1) if figure 1 As shown, a PDMS substrate 1 with multiple micro-through holes 2 that are not connected to each other is prepared by a one-time overmolding process, and the surface of the PDMS substrate 1 is silanized;

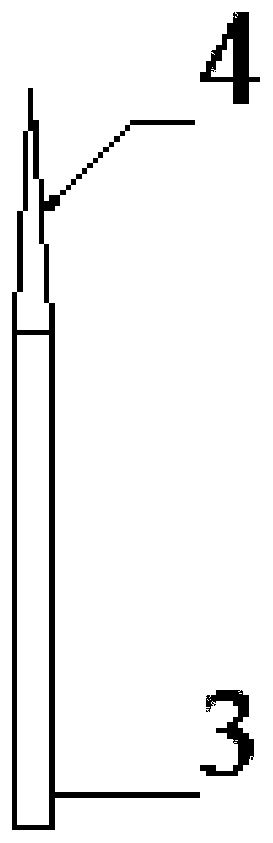

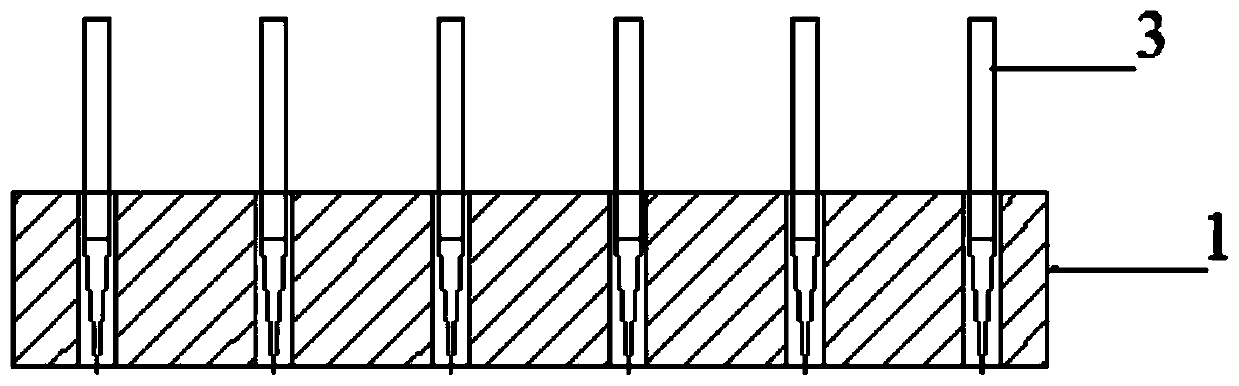

[0034] (2) Microneedles use commercial 0.12*5mm sterile stainless steel acupuncture needles, figure 2 The shown microneedles are arranged in a PDMS substrate 1 with micro-through holes 2, and the microneedles are perpendicular to the surface of the substrate 1 to form a square microneedle array; as image 3 As shown, each metal microneedle tip 4 is flush with the upper surface of the substrate 1, and the microneedle body 3 is located at the lower part of the substrate;

[0035] (3) Preparation of conductive prepolymer: mix conductive filler with PDMS or epoxy resin solution in a...

Embodiment 2

[0039] refer to Figure 9 , the method for preparing a metal microneedle array dry electrode based on a flexible substrate in this embodiment includes the following steps:

[0040] (1) Prepare substrate 1 with micro-through holes 2, such as Figure 6 Shown, preparation method is identical with embodiment 1;

[0041] (2) Microneedle fixation and arrangement: The microneedles are commercially available 0.12*5mm sterile stainless steel acupuncture needles, and the microneedles are arranged in the PDMS substrate 1 with micro-through holes 2 to form a circular microneedle array. The needle tip is flush with the upper surface of the substrate;

[0042] (3) Preparation of conductive prepolymer: mix conductive filler with PDMS or epoxy resin solution in a certain proportion; conductive filler can be carbon black, graphite, nano-silver. In this embodiment, conductive graphite is selected as the conductive filler, the main agent of PDMS and the curing agent are polymer solutions, and...

Embodiment 3

[0046] This embodiment is similar to Embodiment 2, except that the microneedles in this embodiment are titanium microneedles, and the heights of the microneedles exposed to the flexible substrate are different. Schematic diagram of the microneedle electrode Figure 8 shown.

[0047] It should be noted that the number, position, arrangement and height of the exposed flexible substrate are not limited to Figure 5 , Figure 7 , Figure 8 The situation shown can be adjusted arbitrarily according to actual needs.

[0048] In addition, in the prior art, silicon is generally used as the preparation material of microneedles, and the corresponding preparation method generally adopts photolithography and etching processes, but this method has the following disadvantages: (1) The preparation cost is high, and a clean room and photolithography are required. (2) The preparation process is complex, requiring steps such as gluing, exposure, development, and corrosion; (3) The material o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com