Suction nozzle for automatic chip mounter and automatic chip mounter

An automatic placement machine and motion technology, which is used in the assembly of printed circuits with electrical components, electrical components, and printed circuit manufacturing. The effect of increasing the amount of light transmitted and improving the placement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 4 example

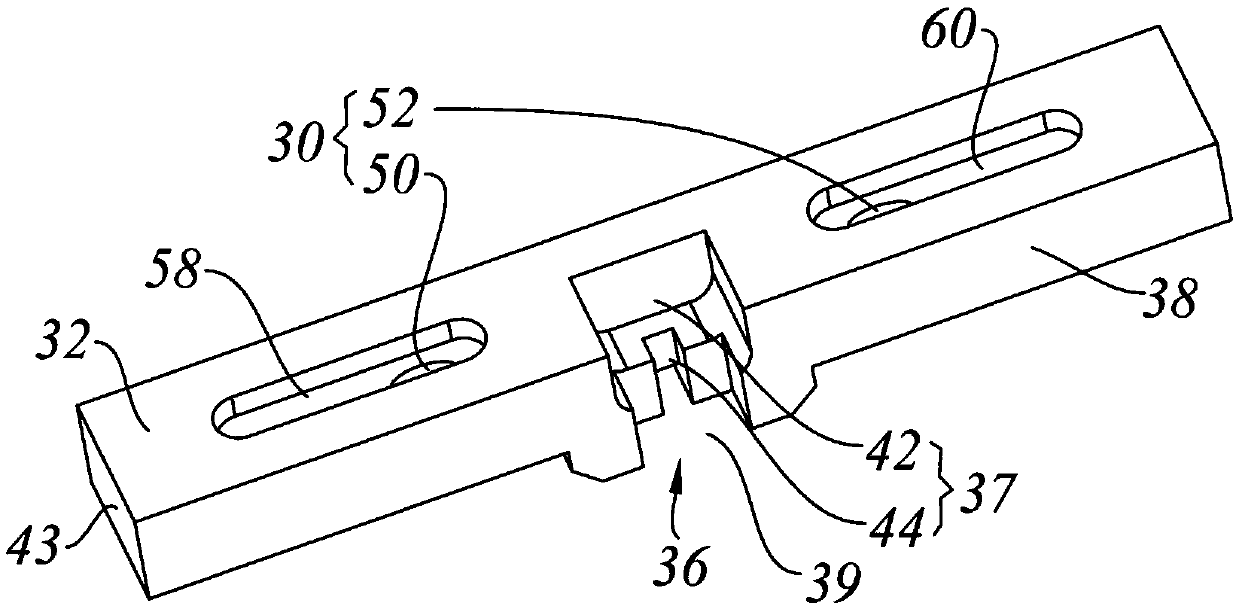

[0053] Such as Figure 11 As shown, the fourth embodiment provided by the present invention is different from the first embodiment in that the location of the negative pressure port is different. In the following, only the different parts will be introduced in detail, and the parts that are the same as those in the first embodiment will not be introduced again.

[0054] In this embodiment, the negative pressure port 74 is located on the second side surface 76 . Of course, the negative pressure port 74 can also be disposed on the first side surface. There are two negative pressure ports 74. Specifically, the negative pressure port 74 includes a first negative pressure port 78 and a second negative pressure port 80, and both the first negative pressure port 78 and the second negative pressure port 80 are arranged on the second side. on surface 76. Certainly, both the first negative pressure port 78 and the second negative pressure port 80 may also be disposed on the first sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com