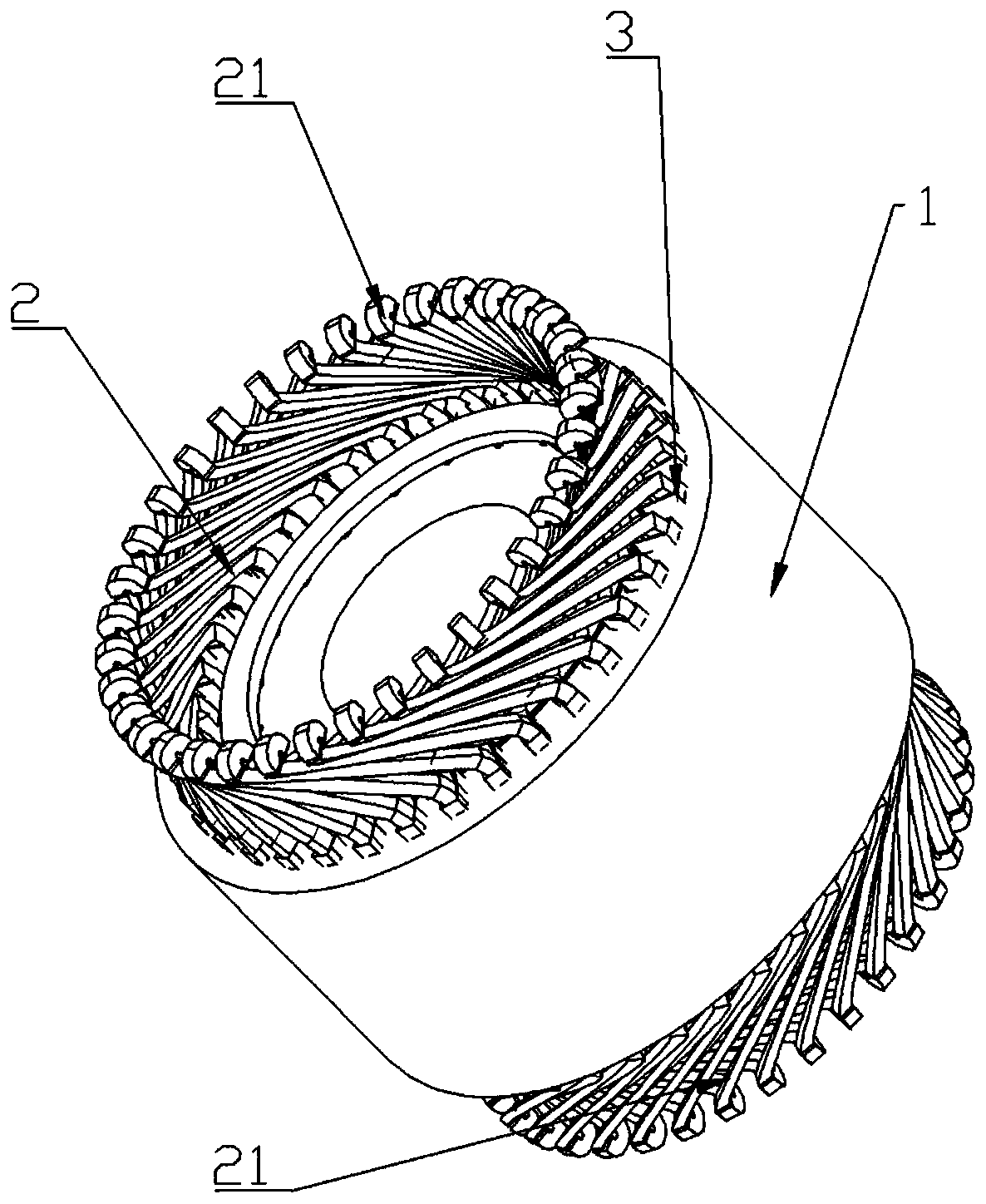

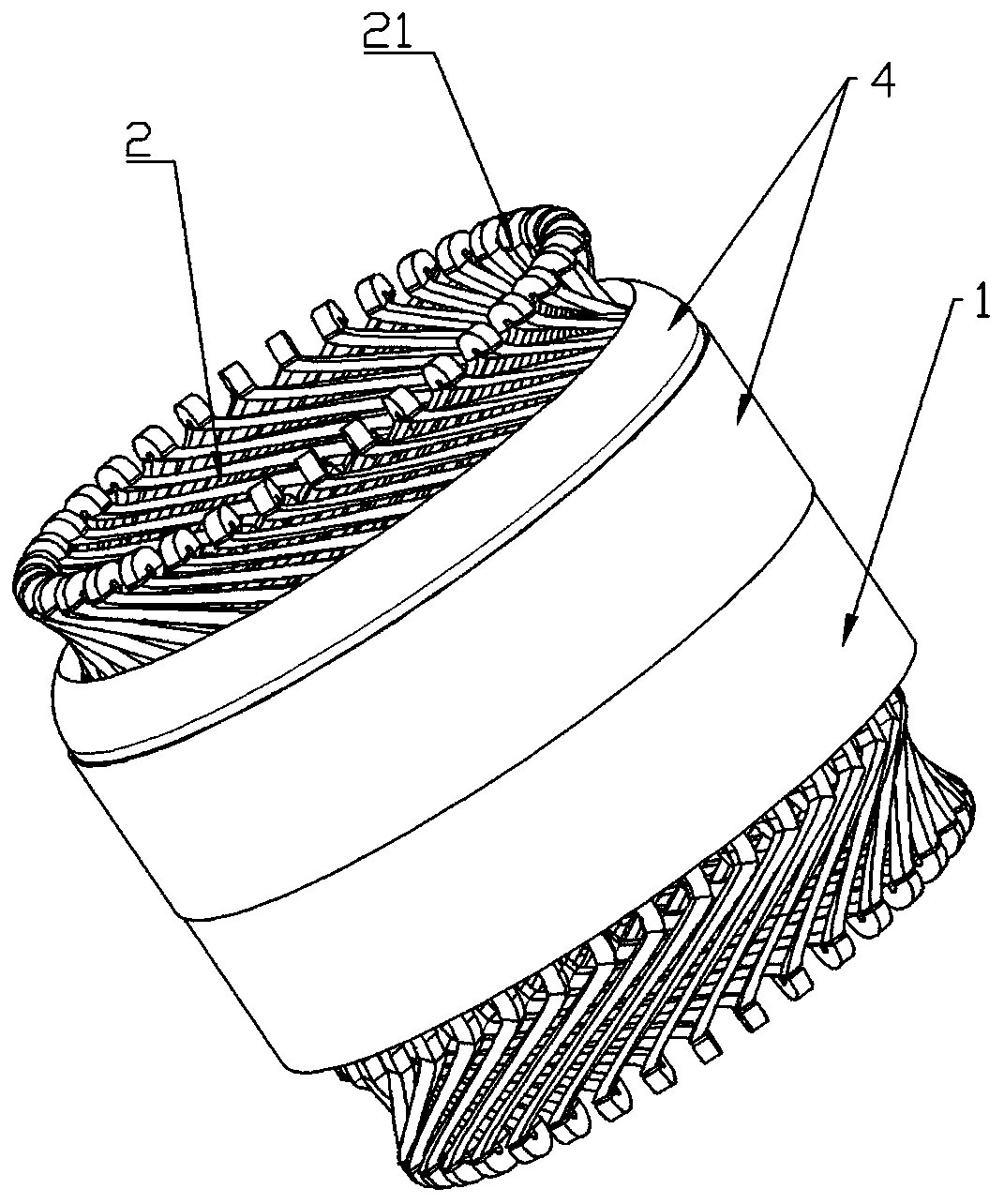

Heat radiation structure of motor stator winding

A technology of motor stator and heat dissipation structure, which is applied to windings, electric components, electrical components, etc., and can solve problems such as low efficiency and complex heat dissipation structure of the motor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The Maer wind motor is used as the test motor stator winding, and the centralized winding method is adopted, and the motor insulation level is B; the test is carried out by the resistance temperature measurement method, and the ambient temperature is 28°C during the test; and two motors are prepared as this test. The samples of the second experiment are numbered as motor No. 1 and motor No. 2; among them:

[0034] Motor No. 1: It is an unprocessed blank motor, and there is no other additional heat dissipation structure;

[0035] Motor No. 2: a processing motor with a heat-conducting structural layer arranged between the end of the winding and the stator core;

[0036] The thermally conductive structure layer uses thermally conductive silicone grease, and the test is carried out after the thermally conductive silicone grease is completely cured.

[0037] On No. 1 motor and No. 2 motor, there are 9 temperature measuring points, numbered A, B, C, D, E, F, G, H, I. On the...

Embodiment 2

[0042] Wenzhou Weipu Motor is used as the test motor stator winding, and the distributed winding method is adopted, and the insulation level of the motor is Class E; the test is carried out by directly applying voltage to the stator winding, and two motors are prepared as samples for this experiment. And numbered as No. 1 motor and No. 2 motor; the test time is 120min, of which:

[0043] Motor No. 1: It is an unprocessed blank motor, and there is no other additional heat dissipation structure;

[0044] Motor No. 2: a processing motor with a heat-conducting structural layer arranged between the end of the winding and the stator core;

[0045] On the No. 1 motor and the No. 2 motor, there are 4 temperature measuring points, numbered A, B, C, and D. On the No. 1 motor, A and B are set at the winding end of one side and the temperature measuring points are equidistantly distributed; , D temperature measuring points, and C, D temperature measuring points are equally spaced and ev...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com