Structure and method for assembling battery top cover and pole

A technology of assembling structure and top cover, which is applied in the manufacture of secondary batteries, non-aqueous electrolyte batteries, electrolyte batteries, etc. The effect of reducing assembly cost, reducing assembly difficulty, and improving overcurrent capability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

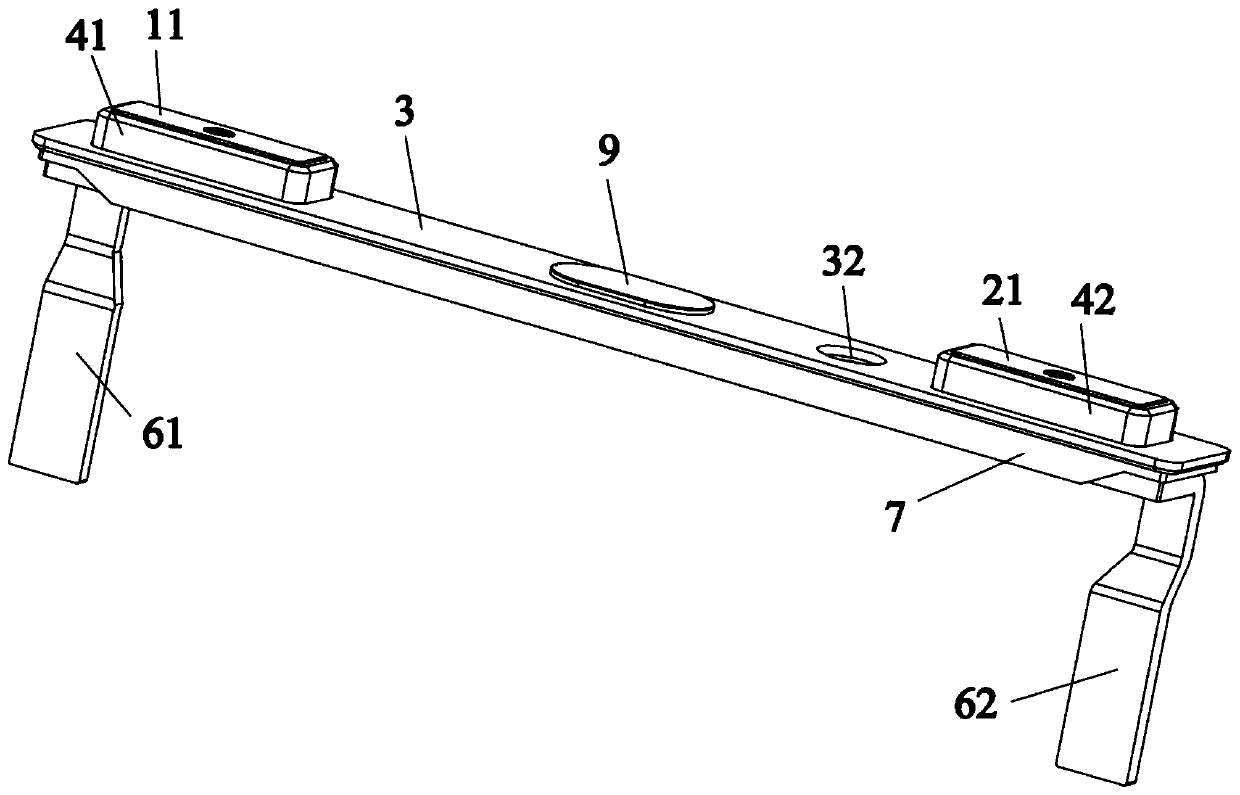

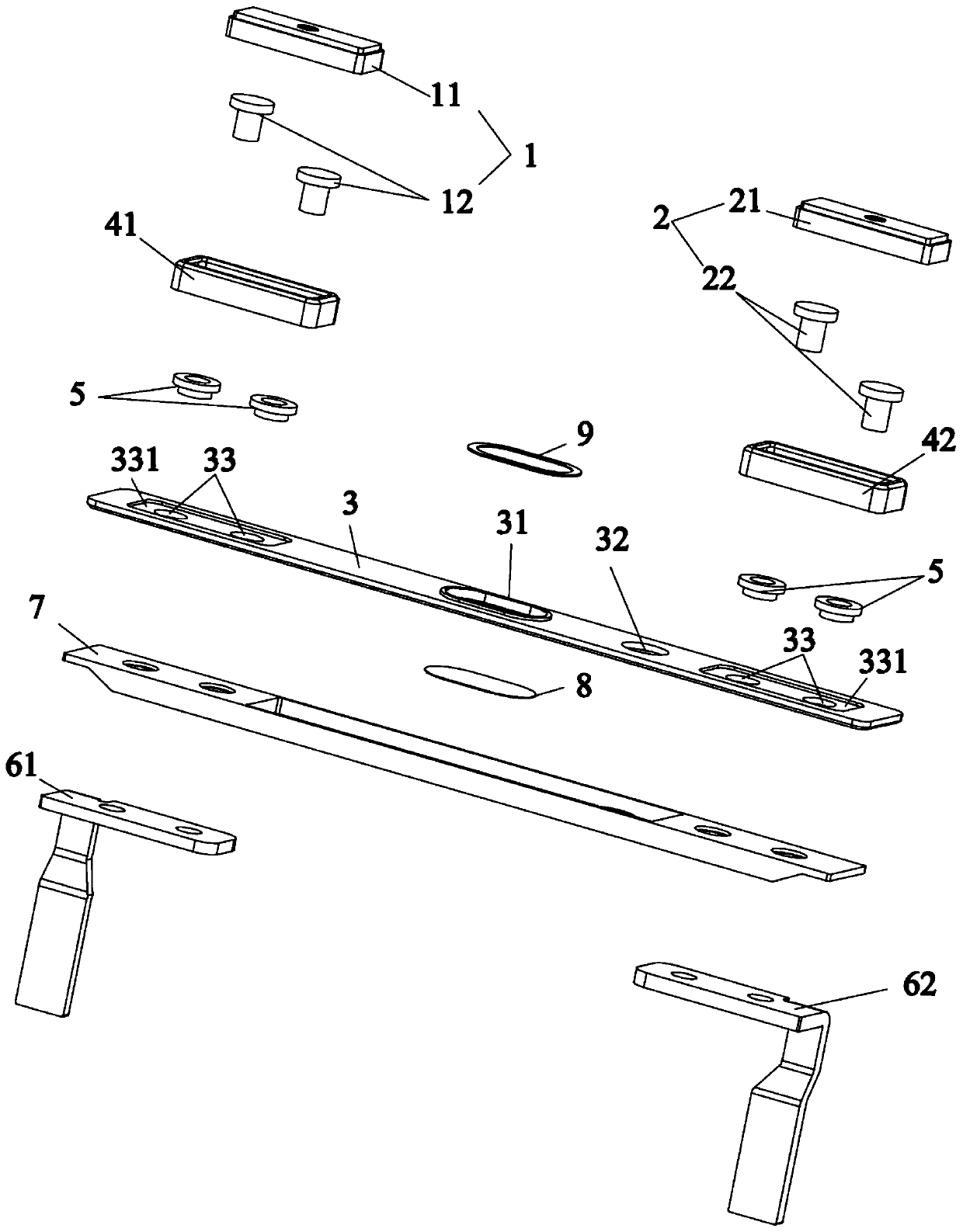

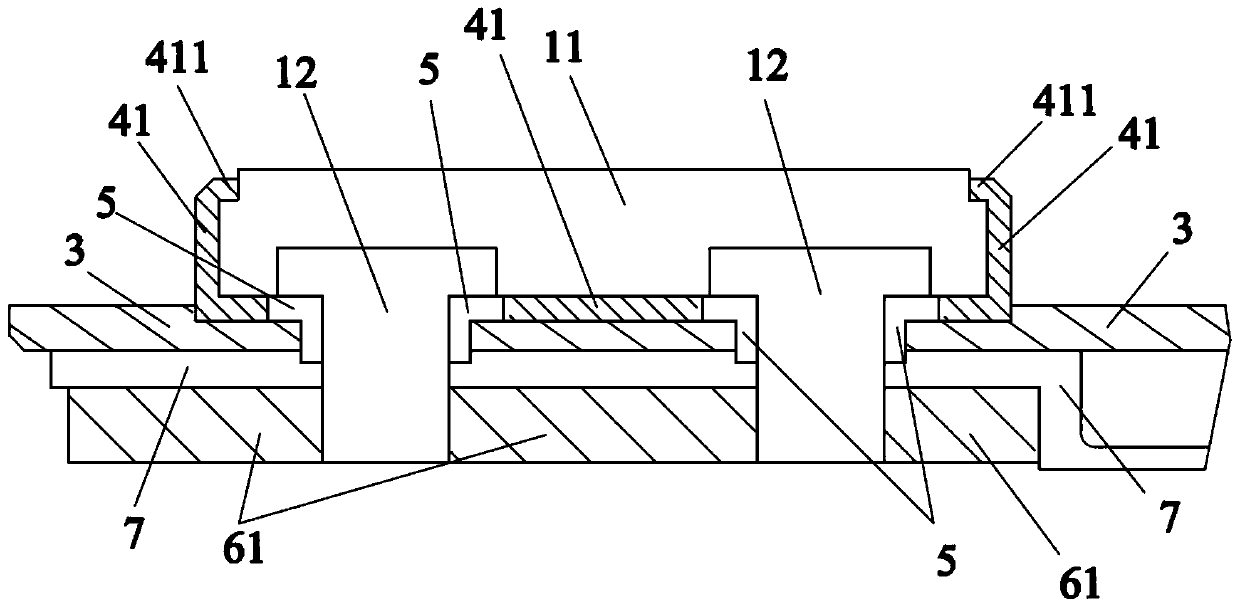

[0034] Such as Figure 1~6 As shown, an assembly structure of a battery top cover and a pole, including a top cover sheet 3, a first pole 1 and a second pole 2 installed on the top cover sheet 3, the first pole 1 and the top cover sheet 3 The first plastic part 41 is formed by encapsulation between the second pole 2 and the top cover sheet 3, and the second plastic part 42 is formed by encapsulation between the second pole 2 and the top cover sheet 3. The first pole 1 includes a first metal block 11 and at least one A metal block 11 is a first metal nail 12 with a concave-convex fit. The first metal nail 12 is welded to the first metal block 11. The second pole 2 includes a second metal block 21 and at least one second metal block 21 with a concave-convex fit. Two metal nails 22 , the second metal nails 22 are welded to the second metal block 21 . Since the pole is generally composed of a bottom base and a cylinder connected to the bottom base, if the materials of the two are...

Embodiment 2

[0044] The difference from Example 1 is that the resistance of the conductive plastic in this example is 1001Ω~30000Ω. The resistance of the conductive plastic is further limited, so that when the battery fails, the positive pole and the negative pole are connected to form an internal protection circuit, while ensuring the safety performance of the battery.

[0045] Other structures are the same as those in Embodiment 1, and will not be repeated here.

Embodiment 3

[0047] Such as Figure 1~6 As shown, an assembly method of a battery top cover and a pole, comprising:

[0048] Insert at least one first metal nail 12 into the first groove 111 at the bottom of the first metal block 11, and then weld along the gap formed between the first groove 111 and the first metal nail 12, so that the first metal nail 12 welded to the first metal block 11 to form the first pole 1;

[0049] Insert at least one second metal nail 22 into the second groove 211 at the bottom of the second metal block 21, and then weld along the gap formed between the second groove 211 and the second metal nail 22, so that the second metal nail 22 welded to the second metal block 21 to form the second pole 2;

[0050] The first pole 1 and the second pole 2 are accommodated in the recess 331 of the pole installation hole 33, and then the first plastic part 41 is glued between the first pole 1 and the top cover sheet 3, and the second The plastic part 42 is glued between the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com