Press-fitting method and press-fitting system for assembling battery core into housing

A battery pre-pressing technology, which is applied in the field of pressing methods and systems for battery cells, can solve the problems of poor stability and low efficiency, achieve good stability, improve stability and efficiency, and press-fit The effect of high efficiency and cell excellent rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046]The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments. The descriptions of "first", "second" and so on in the present invention are only for the purpose of description, and should not be understood as indicating or implying their relative importance or implicitly indicating the quantity or order of the indicated technical features. Thus, the features defined as "first" and "second" may explicitly or implicitly include at least one of these features. In the description of the present invention, "plurality" means at least two, such as two, three, etc., unless otherwise specifically defined.

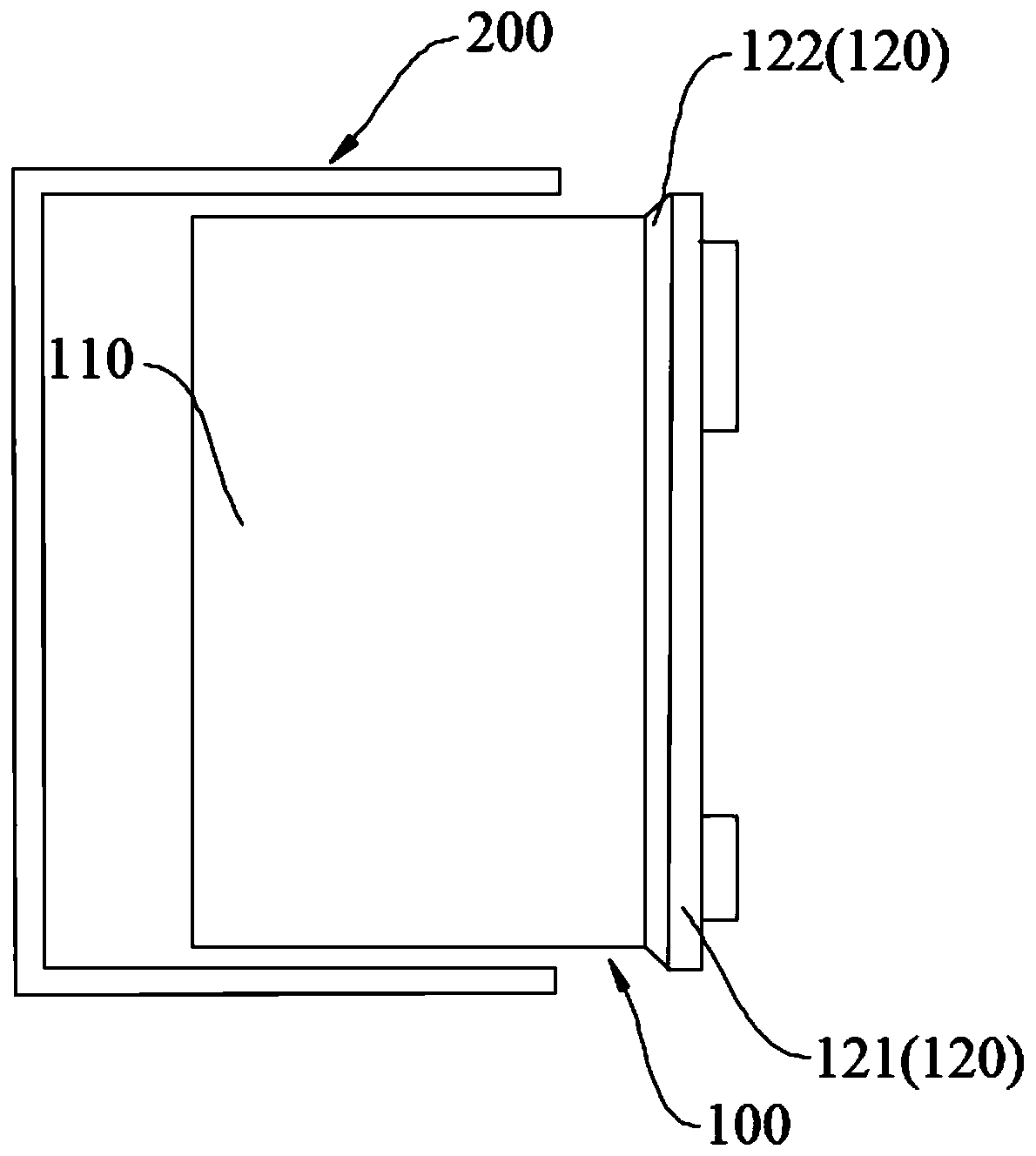

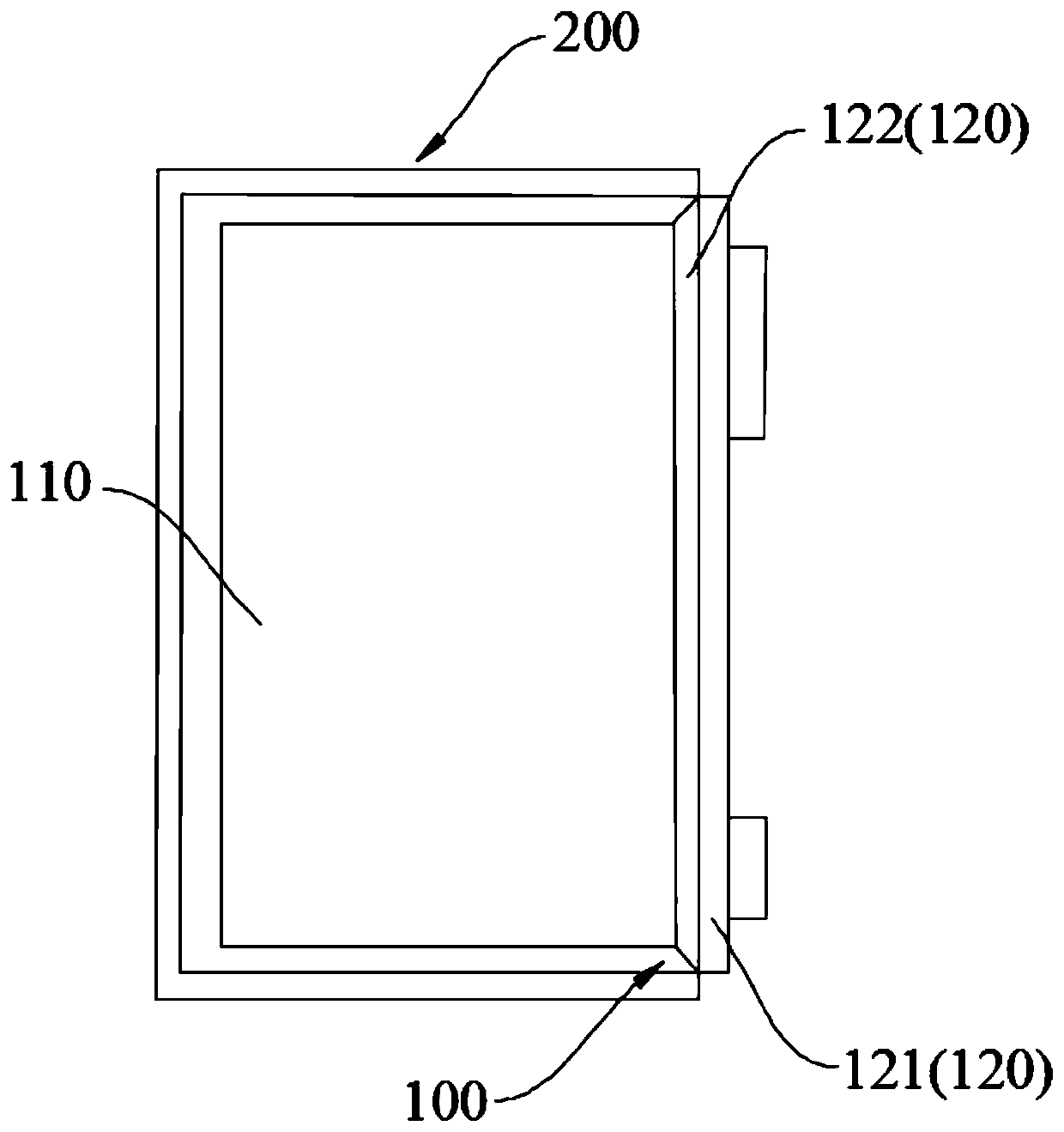

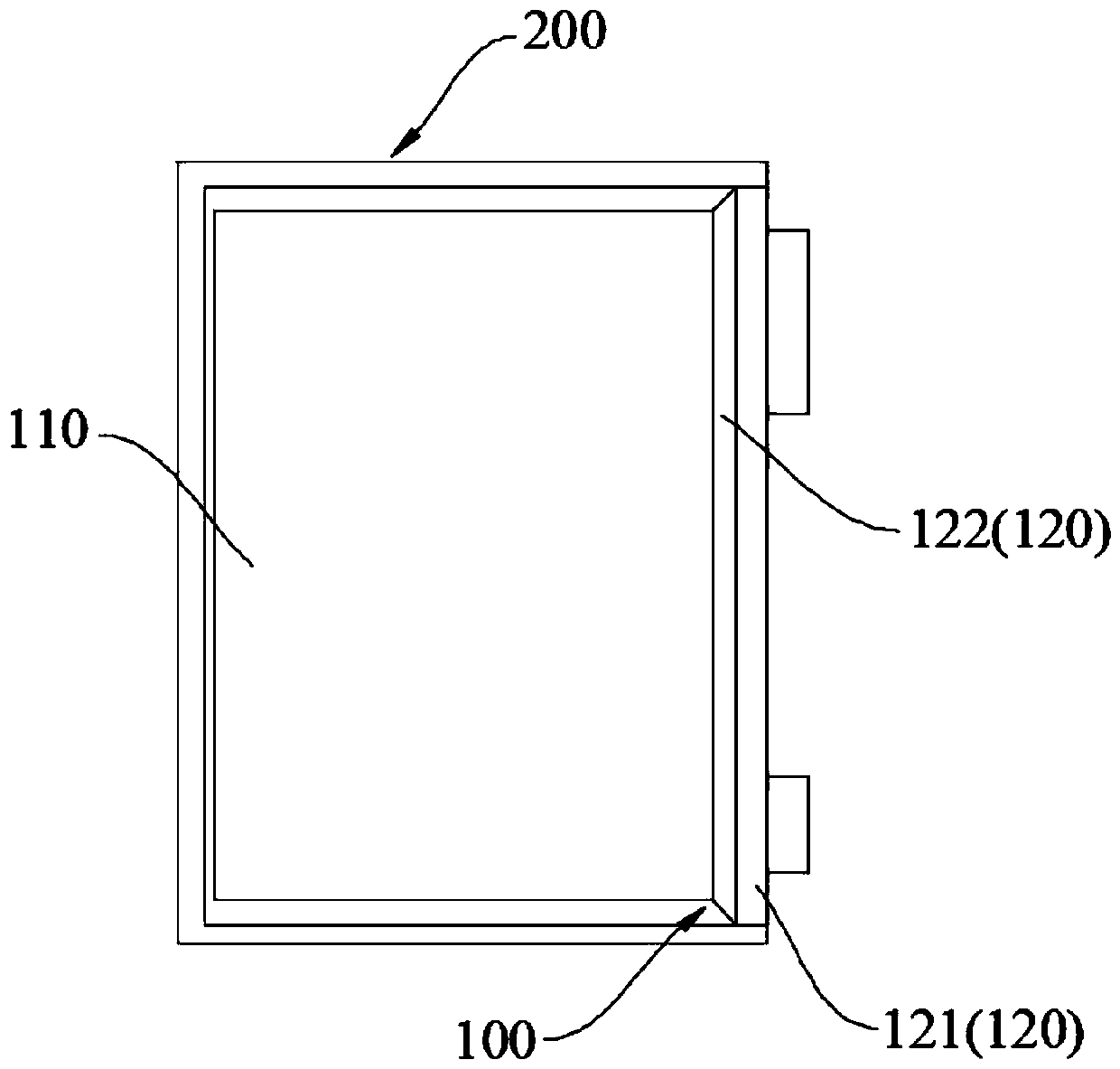

[0047] refer to Figure 2a , Figure 2b , the embodiment of the present application provides a method of press-fitting the cell into the shell, including the following steps: performing horizontal pre-press-fitting of the cell 100 and the casing 200, so that the guide area 122 of the top cover 120 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com