Preparation method of manganese dioxide/carbon-based flexible electrode material

A carbon-based flexible, electrode material technology, applied in the manufacture of hybrid/electric double-layer capacitors, hybrid capacitor electrodes, etc., to achieve the effects of good electrical conductivity, good chemical stability, and low preparation cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

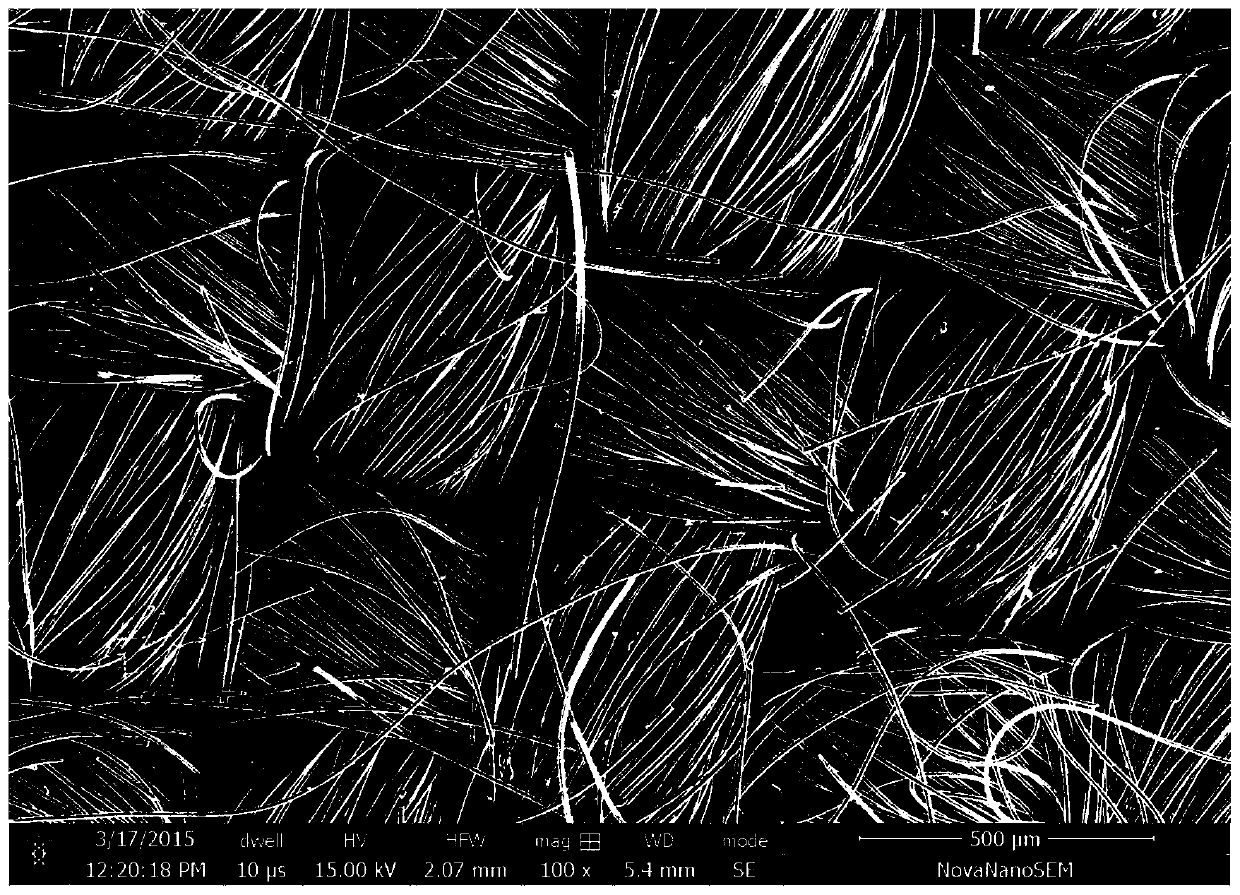

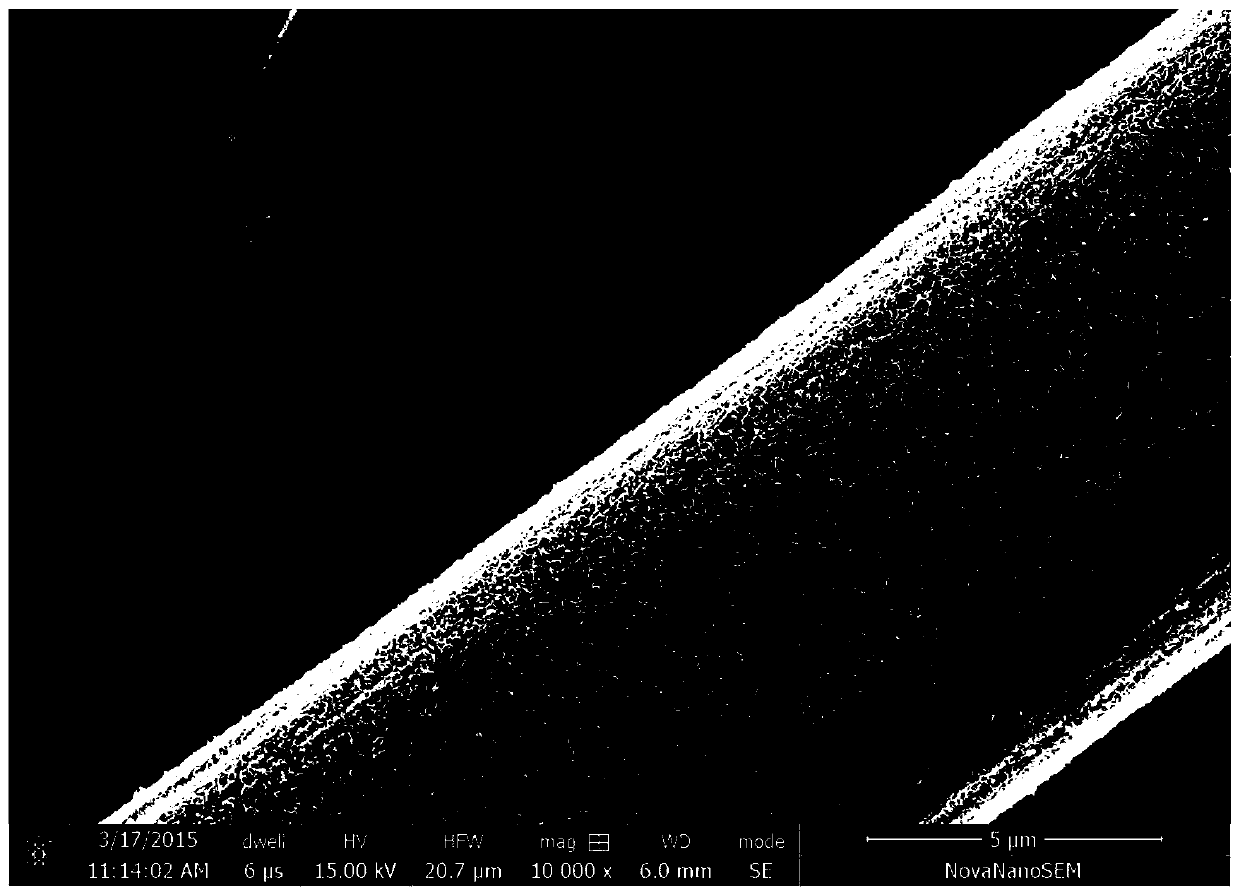

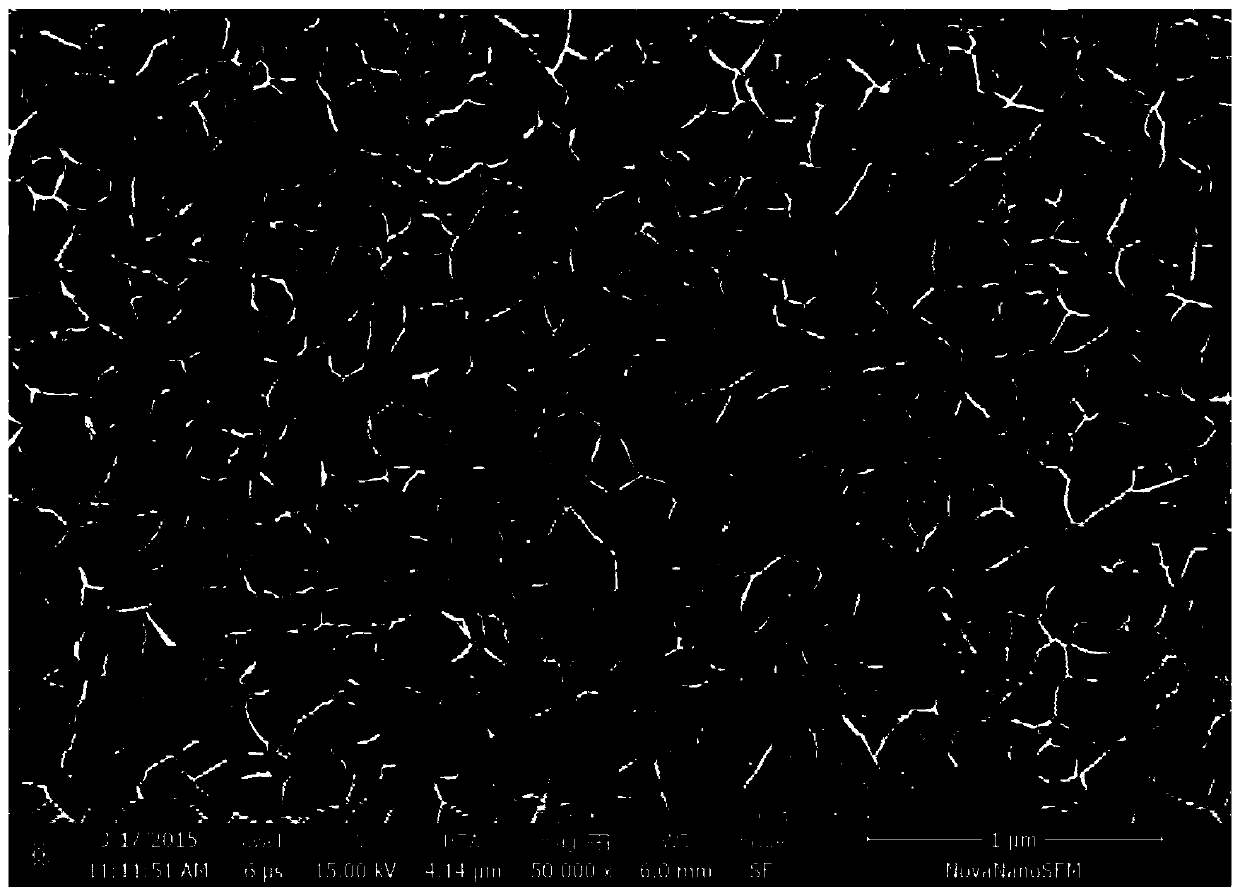

Image

Examples

Embodiment 1

[0051] (1) Divide 2×2cm 2 The carbon cloth was ultrasonically cleaned with acetone, deionized water, and ethanol for 30 minutes, and dried at 35°C;

[0052] (2) Place the cleaned carbon in a mixed acid solution of concentrated nitric acid:concentrated sulfuric acid=1:3, and immerse in ultrasonic for 30min;

[0053] (3) Potassium permanganate was weighed and dissolved in 30mL deionized water to obtain a solution with a concentration of 20mM. The solution was placed in a beaker and stirred for 20min to completely dissolve it;

[0054] (4) Put the mixed acid-treated carbon cloth into a beaker and ultrasonically treat it for 30 minutes;

[0055] (5) Place the beaker in a water bath and heat it to 85°C for 3 hours;

[0056] (6) Naturally cool the carbon cloth after heat treatment to room temperature, wash it with deionized water and absolute ethanol in sequence, and dry it under vacuum at 60°C for 8 hours to obtain a loading capacity of about 2 mg cm -2 MnO 2 / carbon cloth com...

Embodiment 2

[0059] (1) Divide 2×2cm 2 The carbon felt was ultrasonically cleaned with acetone, deionized water, and ethanol for 90 minutes, and dried at 90°C;

[0060] (2) Place the cleaned carbon felt in a mixed acid solution of concentrated nitric acid:concentrated sulfuric acid=1:1, and immerse in ultrasonic for 30min;

[0061] (3) Dissolve sodium permanganate in 30 mL deionized water to obtain a solution with a concentration of 1000 mM, place the solution in a beaker, and stir for 60 min to completely dissolve it;

[0062] (4) Put the mixed acid-treated carbon felt into a beaker, and ultrasonically treat it for 40 minutes;

[0063] (5) Place the beaker in a water bath and heat it to 90°C for 8 hours;

[0064] (6) Naturally cool the carbon felt to room temperature after heat treatment, wash it with deionized water and absolute ethanol in sequence, and dry it under vacuum at 80°C for 12 hours to obtain a loading capacity of about 4.5 mg cm -2 MnO 2 / Carbon felt composite material, t...

Embodiment 3

[0067] (1) Divide 2×2cm 2 The flexible graphene paper was ultrasonically cleaned with acetone, deionized water, and ethanol for 10 minutes, and dried at 45°C;

[0068] (2) Place the cleaned graphene paper in a mixed acid solution of concentrated nitric acid:concentrated sulfuric acid=1:2, and immerse in ultrasonic for 30min;

[0069] (3) Weigh lithium permanganate and dissolve it in 30mL deionized water to obtain a solution with a concentration of 10mM. The solution is placed in a beaker and stirred for 20min to completely dissolve it;

[0070] (4) Put the graphene paper treated with mixed acid into a beaker, and ultrasonically treat it for 20 minutes;

[0071] (5) Place the beaker in a water bath and heat it to 40°C for 0.5h;

[0072] (6) Naturally cool the graphene paper after heat treatment to room temperature, wash it sequentially with deionized water and absolute ethanol, and dry it in vacuum at 40°C for 4 hours to obtain a loading capacity of about 0.5 mg cm -2 MnO 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com