Topological optimization design method for stand column structure of friction stir welding robot

A technology of friction stir welding and topology optimization, applied in mechanical equipment, instruments, calculations, etc., can solve problems such as welding position deviation, affecting welding quality, welding equipment structure deformation, etc., and achieve the effect of shortening the time of iterative calculation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be described in further detail below in conjunction with the accompanying drawings.

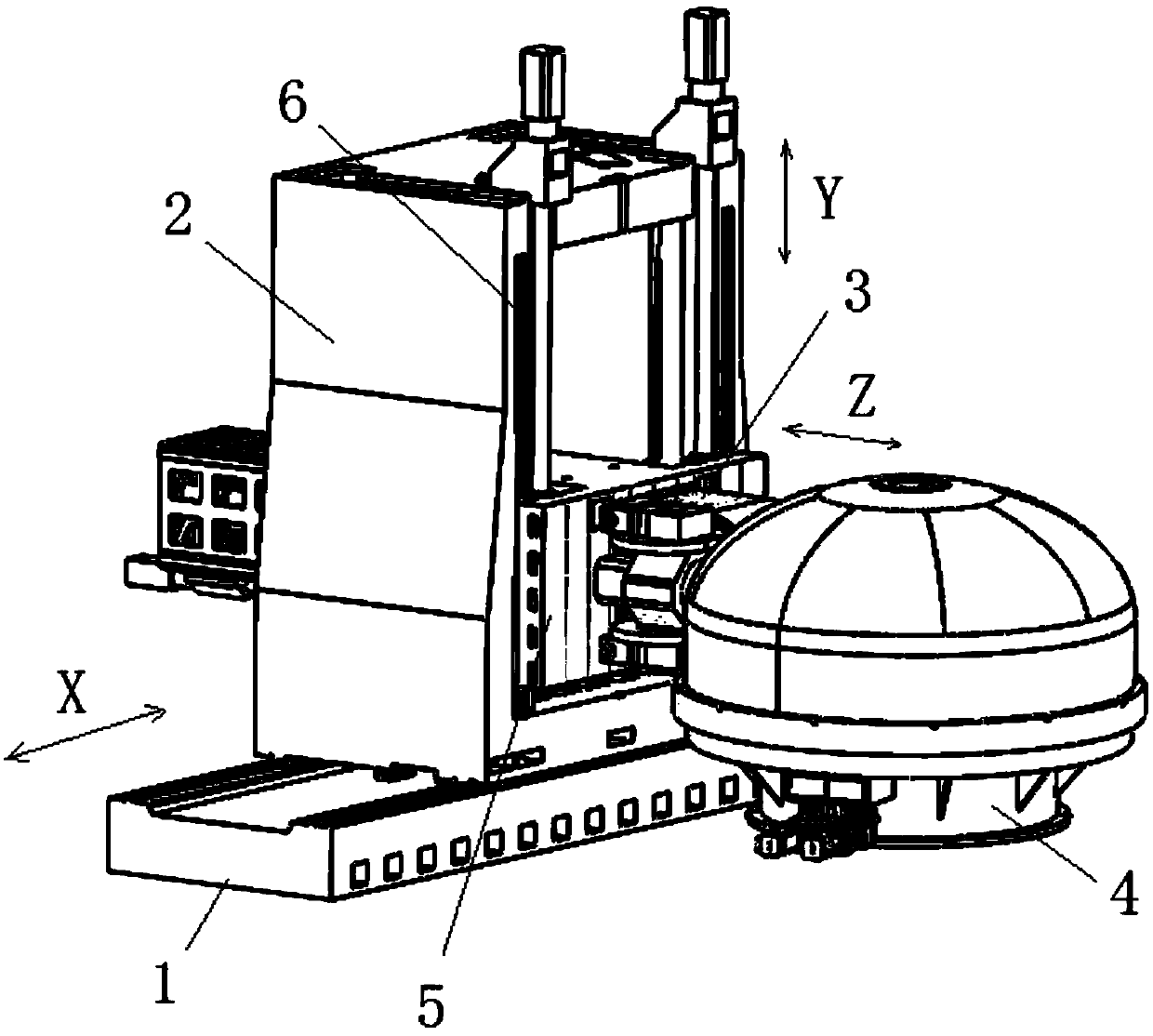

[0042] Such as figure 1 As shown, the welding body part of the friction stir welding robot includes a base 1, a column 2, a ram 3, a turntable 4 and other structures, wherein the column 2 as the Y axis is located between the base 1 of the X axis and the ram 3 of the Z axis. Since the column 2 has many connection positions with other large-scale components, its load situation is relatively complicated. The two ends are also connected to the saddle 5 on the ram 3 through the guide rail slider pair 6 and the ball screw pair, and the above connection structures are known technologies in the art.

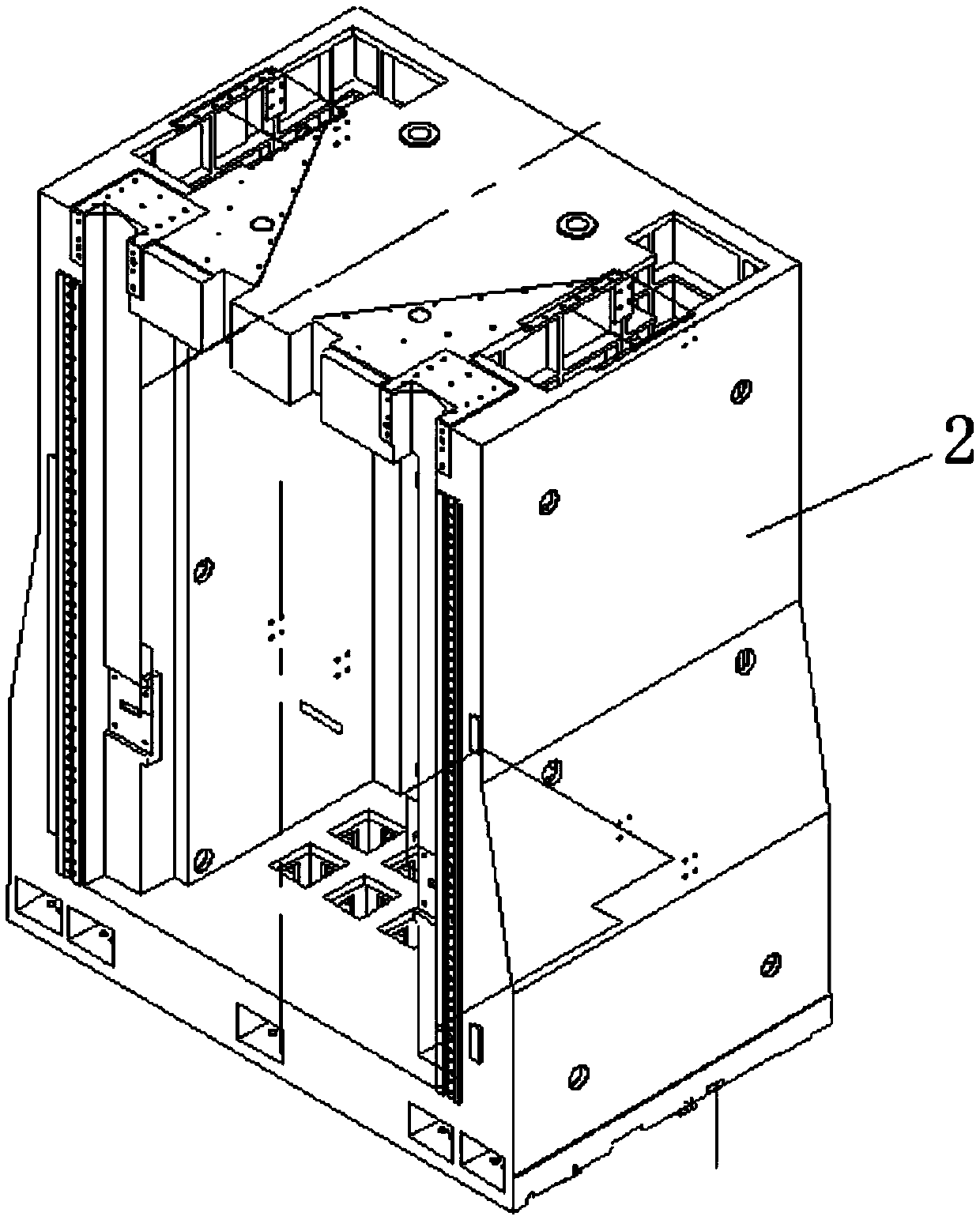

[0043] Such as figure 2 As shown, the present invention is mainly aimed at optimizing the design of the column 2 of the Y axis. The purpose of the design is to obtain a structure of the column 2 with better comprehensive dynamic characteristics. Various types of ribs a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com