Longitudinal and transverse sliding construction process of steel box girder

A construction process and technology of steel box girder, applied in bridges, bridge materials, bridge construction, etc., can solve problems such as poor geological conditions, affecting the working space of hoisting machinery and equipment, affecting the walking of hoisting machinery and transportation vehicles, etc., to improve safety. production effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0051] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

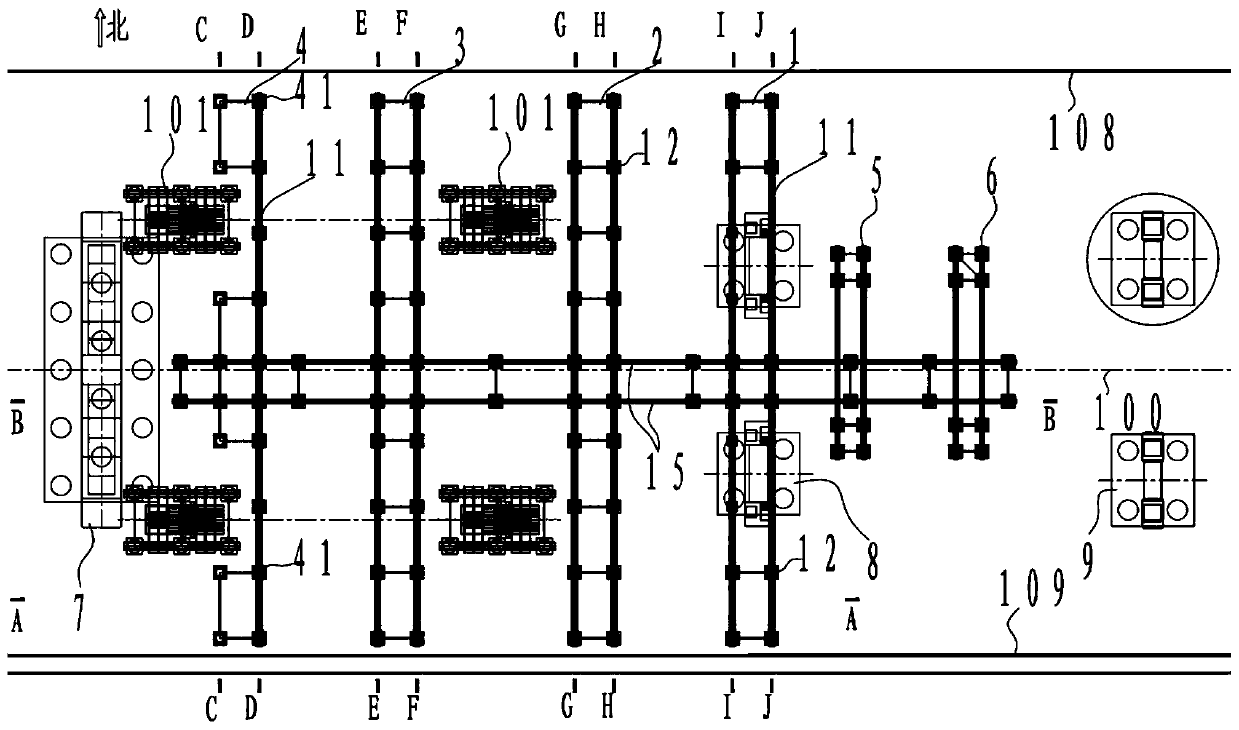

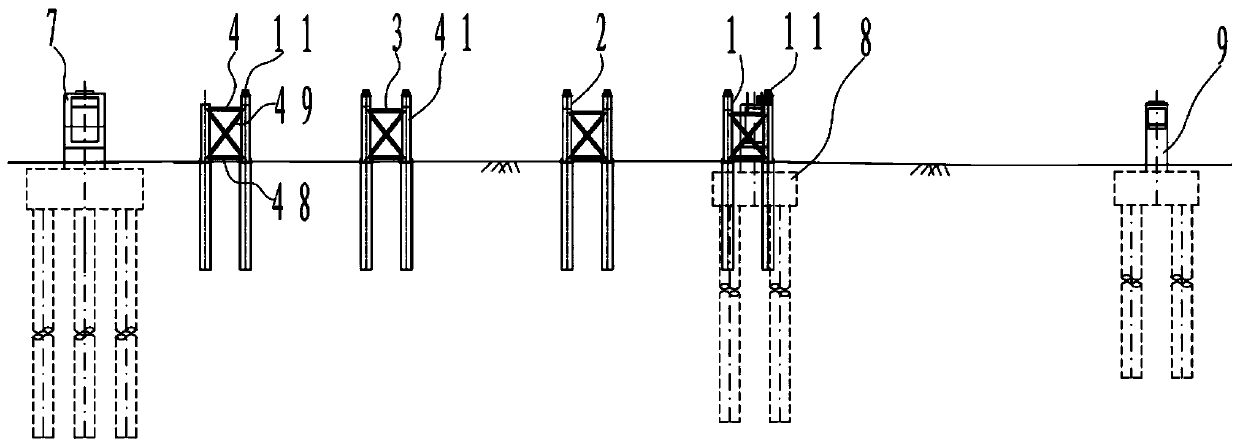

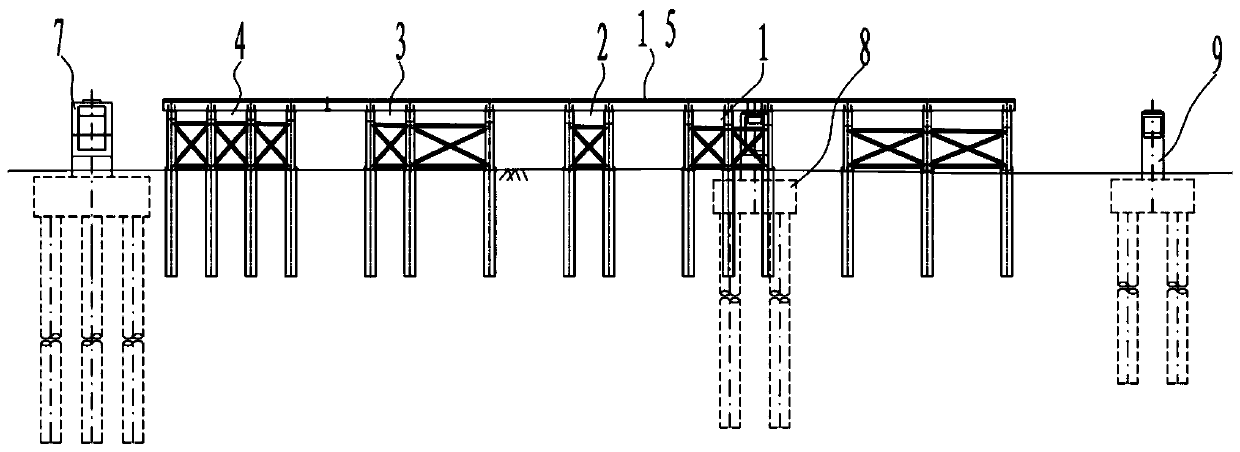

[0052] attached figure 1 - attached Figure 11 It is a schematic diagram of the vertical and horizontal structure of the steel box girder, with Figure 12 - attached Figure 19 It is a schematic diagram of the construction steps of vertical and horizontal sliding of steel box girder segment blocks, a construction technology of vertical and horizontal sliding of steel box girder, including the following steps:

[0053] 1) Pouring of pier piles, installation of brackets and preparation of gantry cranes, hoists, jacking machines, truck cranes, track trolleys, and three-axis roller trolleys 001. The north-south direction is horizontal, and the east-west direction is vertical.

[0054] The pier piles include a first pier pile 7, a second pier pile 8 and a third pier pile 9 arranged longitudinally in sequence, and the center distance be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com