Graphene/silica/natural rubber composite material, and preparation method and application thereof

A technology of natural rubber and silicon dioxide, applied in the field of rubber materials, can solve the problems of poor dispersibility, poor dispersibility and easy precipitation of white carbon black, and achieve the effects of improving electrostatic conductivity, reducing rolling resistance and improving tearing performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

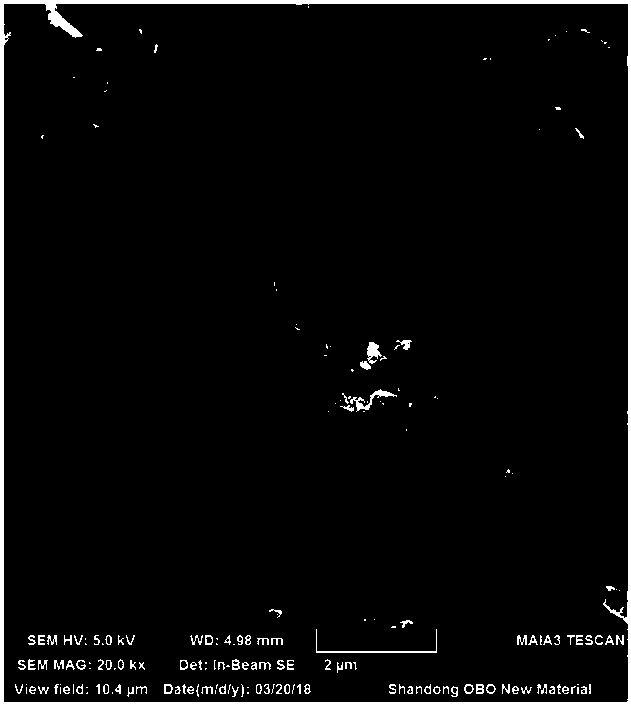

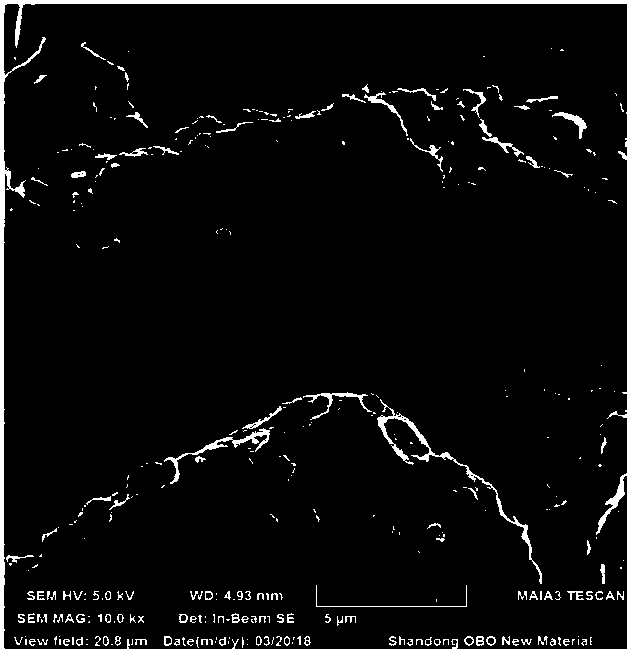

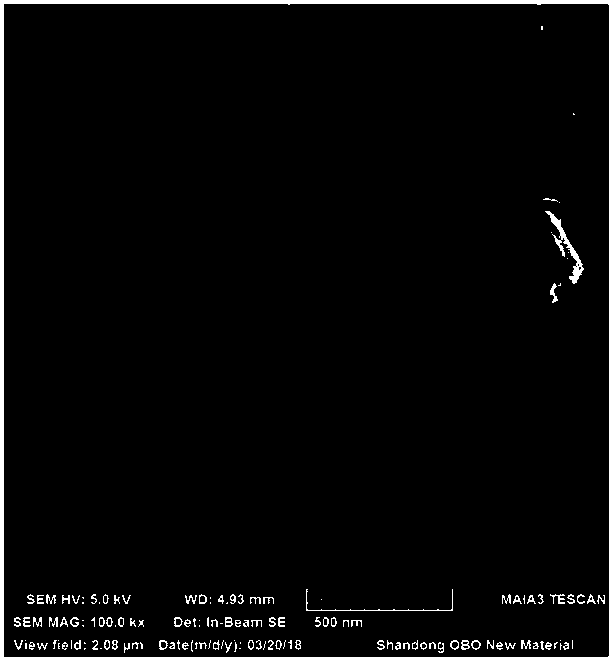

Image

Examples

preparation example Construction

[0063] The present invention also provides a kind of preparation method of graphene / silicon dioxide / natural rubber composite material, comprises the following steps:

[0064] 1) After the graphene oxide aqueous solution and the silica sol are ultrasonically dispersed, a dispersion is obtained;

[0065] 2) After ultrasonically dispersing the dispersion obtained in the above steps and the natural rubber again, a mixed slurry is obtained;

[0066] 3) after reacting the mixed slurry obtained in the above steps and reducing agent, obtain graphene / silica sol / natural rubber composite liquid;

[0067] 4) After the graphene / silica sol / natural rubber composite liquid obtained in the above steps is demulsified, a graphene / silica / natural rubber composite material is obtained.

[0068] The present invention is to the selection, composition and structure of the material in the above-mentioned preparation method, and corresponding optimal principle, and the selection, composition and struct...

Embodiment 1

[0102] Take 10g of graphene oxide, add water to dilute to 3‰, and ultrasonically stir for 1h;

[0103] Add 50 ml of silica sol (40% solid content) dropwise to the graphene oxide slurry at a rate of 10 ml / min, and ultrasonically stir for 1 hour after the addition, to obtain a mixed solution of graphene oxide and silica sol;

[0104] Then the mixed solution of graphene oxide and alkaline silica sol was added dropwise in 150g natural rubber latex with the dropping speed of 15ml / min. Continue ultrasonic stirring for 1 h after the dropwise addition;

[0105] Move the prepared sample to an oil bath, add 10 g of hydrazine hydrate, and react for 24 hours. Add demulsifier dilute sulfuric acid or acetic acid after 24h to demulsify. After breaking the emulsion, it is washed 4 to 6 times by means of suction filtration, and after the washing is completed, it is dried in a vacuum oven to obtain a graphene / silicon dioxide / natural rubber composite material.

[0106] The graphene / silica / nat...

Embodiment 2

[0116] Take 10g of graphene oxide, add water to dilute to 3‰, and ultrasonically stir for 1h;

[0117] Add 100 ml of silica sol (40% solid content) dropwise to the graphene oxide slurry at a dropping rate of 10 ml / min, and ultrasonically stir for 1 h after the addition is complete. Obtain the mixed solution of graphene oxide and silica sol;

[0118] Then the mixed solution of graphene oxide and alkaline silica sol was added dropwise in 150g natural rubber latex with the dropping speed of 15ml / min. Continue ultrasonic stirring for 1 h after the dropwise addition;

[0119]Move the prepared sample to an oil bath, add 10 g of hydrazine hydrate, and react for 24 hours. Add demulsifier dilute sulfuric acid or acetic acid after 24h to demulsify. After breaking the emulsion, it is washed 4 to 6 times by means of suction filtration, and after the washing is completed, it is dried in a vacuum oven to obtain a graphene / silicon dioxide / natural rubber composite material.

[0120] The g...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com