Preparation method for loading copper oxide nanoparticles on surface of in-situ synthesized carbon nanotube

A carbon nanotube and nanoparticle technology, which is applied in the field of nanomaterial preparation, can solve the problems of environmental hazards, poor adhesion of metal decoration layers, and difficult removal of heavy metal elements, and achieves the effect of strong interface adhesion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

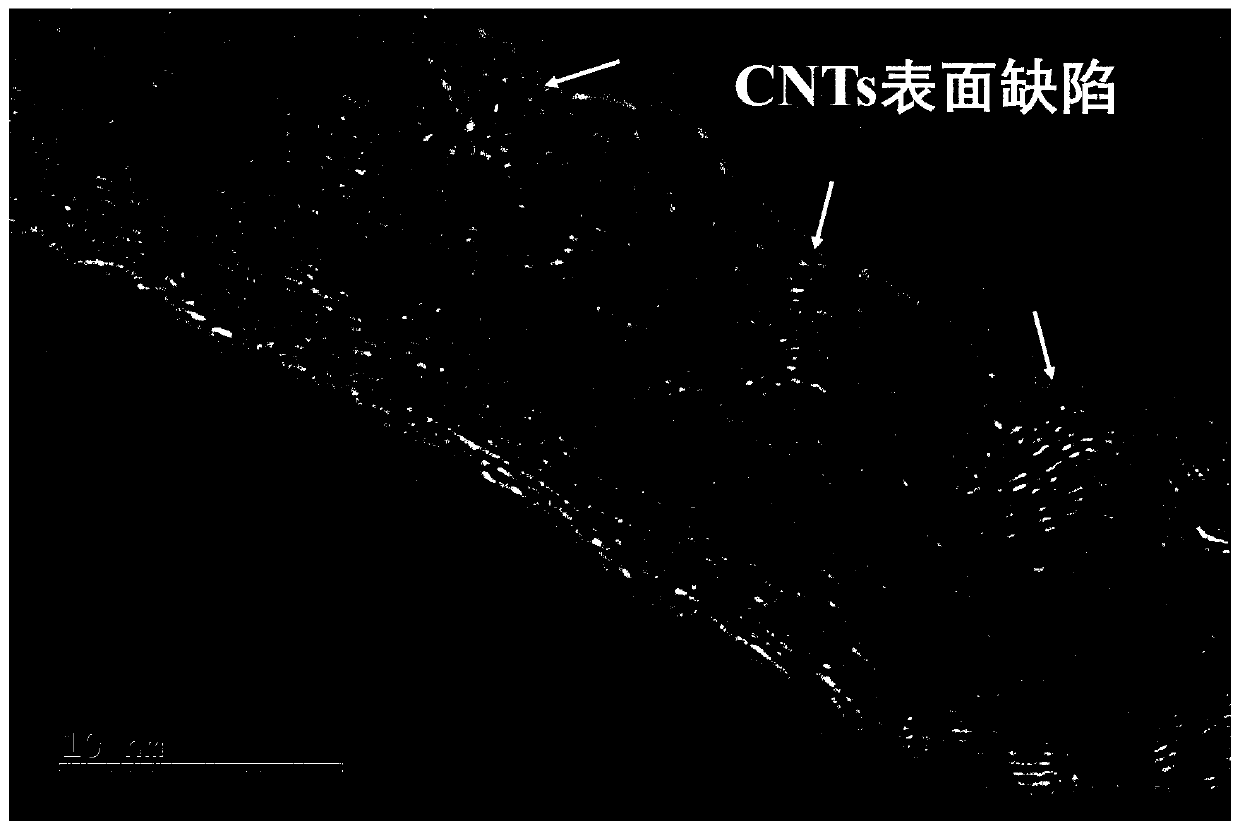

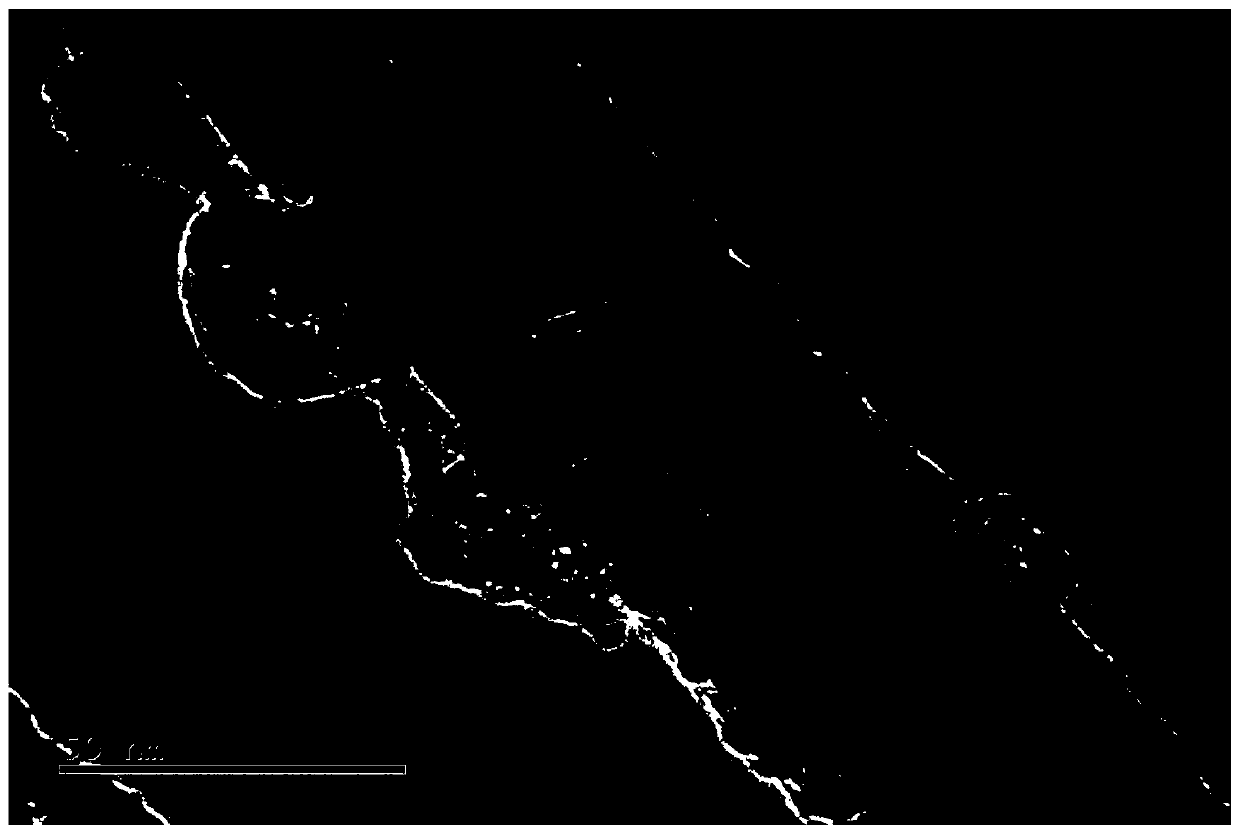

[0032] Weigh 0.8g hydroxylated CNTs (organization morphology as figure 1 Shown) and 1g copper sulfate crystal, be placed in the beaker that volume is 250ml, and add 150ml distilled water. The beaker was placed in a water bath, and magnetically stirred at room temperature for 2 hours to fully mix the hydroxylated CNTs and copper sulfate in the mixed solution. Raise the temperature of the water bath to 90°C, and add 20ml, 2mol / L sodium hydroxide solution dropwise after reaching the temperature. After the reaction is complete, the mixed solution is suction filtered, and the powder obtained by the suction filtration is washed with distilled water, and the washing and suction filtration are repeated 3 times. The obtained mixed powder was placed in a vacuum drying oven at a drying temperature of 80°C and a drying time of 12 hours. The morphology of the powder was as follows: figure 2 shown. It can be found that the copper oxide / copper hydroxide nanoparticles obtained by the prec...

Embodiment 2

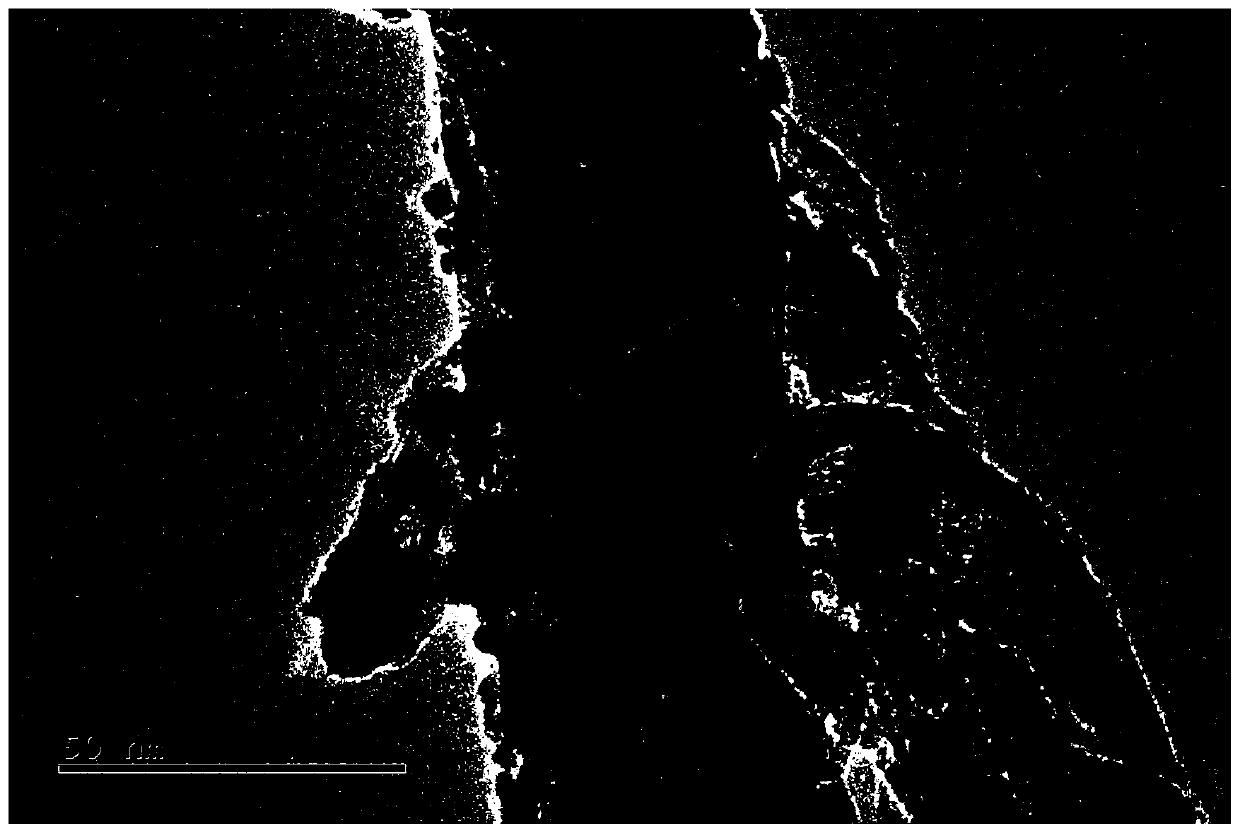

[0034] Weigh 1 g of hydroxylated carbon nanotubes and 1 g of copper sulfate crystals, place them in a beaker with a volume of 250 ml, and add 200 ml of distilled water. Place the beaker in a water bath, and stir magnetically for 2 hours at room temperature to fully mix the hydroxylated carbon nanotubes and copper sulfate in the mixed solution. Raise the temperature of the water bath to 90°C, and add 20ml, 2mol / L sodium hydroxide solution dropwise after reaching the temperature. After the reaction is complete, the mixed solution is suction filtered, and the powder obtained by the suction filtration is washed with distilled water, and the washing and suction filtration are repeated 3 times. The obtained mixed powder was placed in a vacuum drying oven at a drying temperature of 80° C. and a drying time of 12 hours. The dried mixed powder was placed in a muffle furnace for annealing treatment at an annealing temperature of 300 °C and a holding time of 2 h to obtain a CuO@CNTs com...

Embodiment 3

[0036] Weigh 0.8 g of hydroxylated carbon nanotubes and 1 g of copper sulfate crystals, place them in a beaker with a volume of 250 ml, and add 200 ml of distilled water. Place the beaker in a water bath, and stir magnetically for 2 hours at room temperature to fully mix the hydroxylated carbon nanotubes and copper sulfate in the mixed solution. Raise the temperature of the water bath to 100°C, and add 20ml, 2mol / L sodium hydroxide solution dropwise after reaching the temperature. After the reaction is complete, the mixed solution is suction filtered, and the powder obtained by the suction filtration is washed with distilled water, and the washing and suction filtration are repeated 3 times. The obtained mixed powder was placed in a vacuum drying oven at a drying temperature of 80° C. and a drying time of 12 hours. The dried mixed powder was placed in a muffle furnace for annealing treatment at an annealing temperature of 350 °C and a holding time of 2 h to obtain a CuO@CNTs ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elastic modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com