Substrate cleaning device

A technology for cleaning devices and substrates, applied in the direction of electrostatic cleaning, cleaning methods and utensils, cleaning methods using gas flow, etc., can solve problems such as long paths, improve quality and efficiency, prevent dust particles from scattering, and save The effect of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] In order to further illustrate the technical means and effects adopted by the present invention, the following describes in detail in conjunction with the embodiments of the present invention and the accompanying drawings.

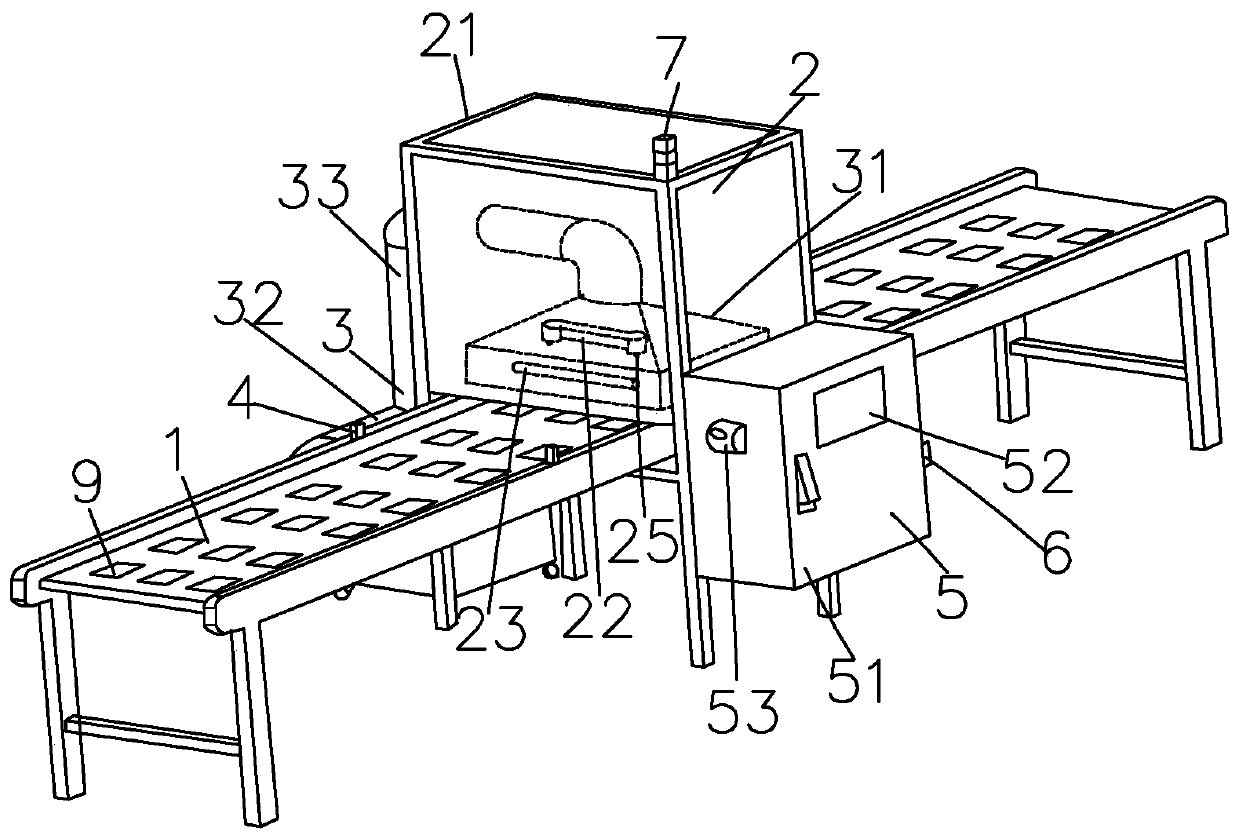

[0035] see figure 1 , the present invention provides a substrate cleaning device, including a conveyor belt 1 for transporting a substrate 9, a cleaning system 2 for cleaning the substrate 9 on the conveyor belt 1, and a device for collecting particles removed from the substrate 9. Dust collection system 3 , grating sensor 4 for detecting whether substrate 9 enters cleaning system 2 , and electrical box 5 electrically connected to cleaning system 2 , dust collection system 3 , and grating sensor 4 .

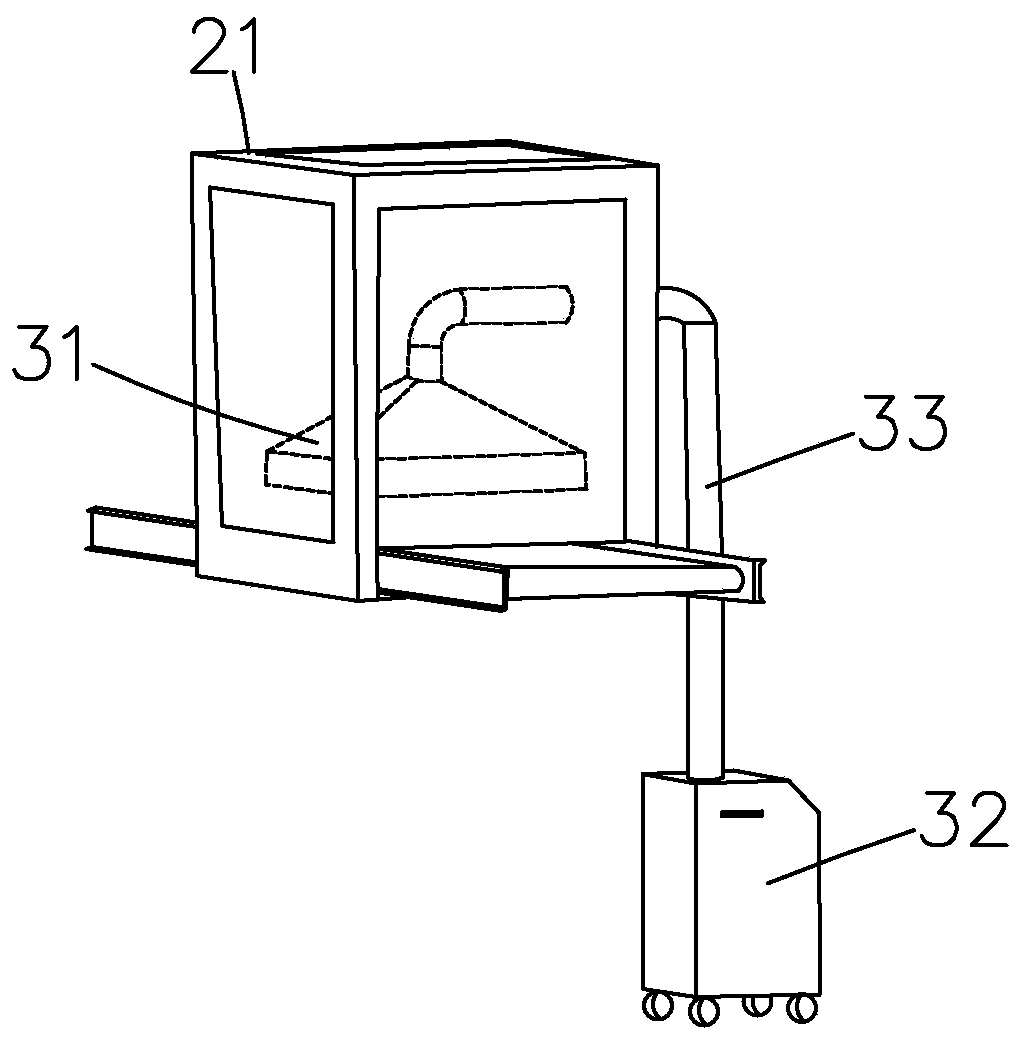

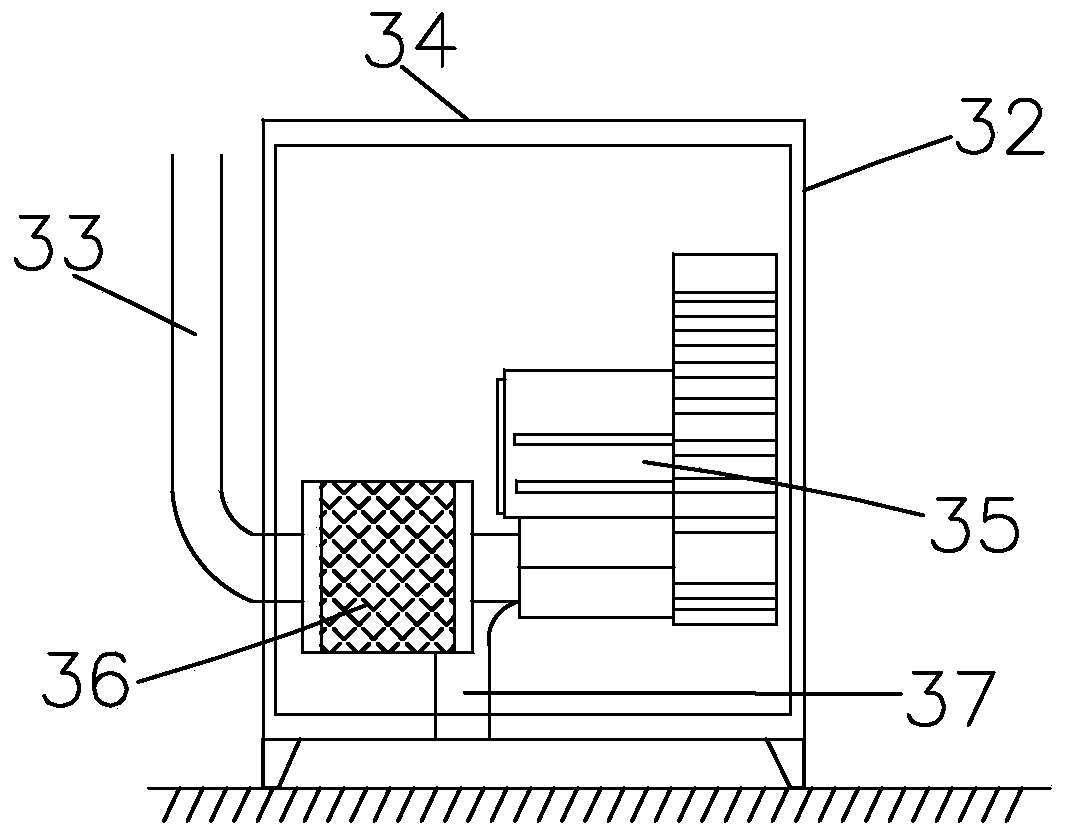

[0036] Specifically, the cleaning system 2 includes a cleaning frame 21 that is located above the conveyor belt 1 and defines a cleaning space above the conveyor belt 1 , and rollers that are sequentially arranged above the conveyor belt 1 in the clean...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com