A fiber grating sensor calibration device based on liquid nitrogen -based cooling cooler

A fiber grating and conduction cooling technology, applied in measurement devices, instruments, scientific instruments, etc., can solve the problems of long heating and cooling time, no unique sensor design, expensive refrigerators, etc., and achieve the effect of reducing heat leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

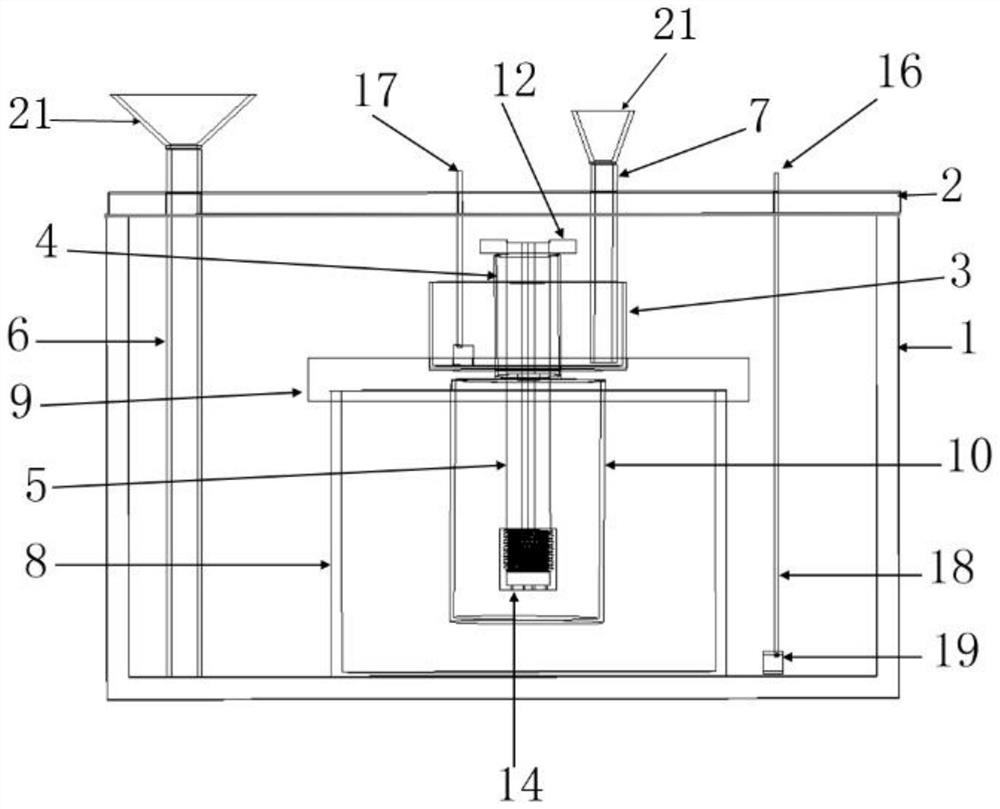

[0038] Such as Figure 1 to Figure 3 As shown, the embodiment of the present invention provides a fiber grating sensor calibration device based on liquid nitrogen conduction cooling, which includes a liquid storage tank 1 , and a liquid storage tank cover 2 is arranged on the top of the liquid storage tank 1 . The liquid storage barrel 1 and the barrel cover 2 are sealed with epoxy resin, which can reduce the temperature exchange between the inside of the tank and the outside.

[0039] The liquid storage barrel 1 is provided with a heat insulating device, a temperature regulating barrel 3, a fiber grating sensor and a temperature reference sensor; Temperature barrel 3; an isolation tube 4 is provided inside the temperature adjustment barrel 3, and the lower end of the isolation tube 4 runs through the bottom of the temperature adjustment barrel 3 and communicates with the heat insulation device.

[0040] The heat insulation device includes a heat insulation barrel 8, the heat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com