Layering pre-force-falling type door stop

A technology of pre-dropping and door suction, which is applied in the direction of building fastening devices, wing leaf fastening devices, buildings, etc., can solve the problems of force drop, etc., to prolong the service life, reduce the effect, improve the strength and The effect of hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

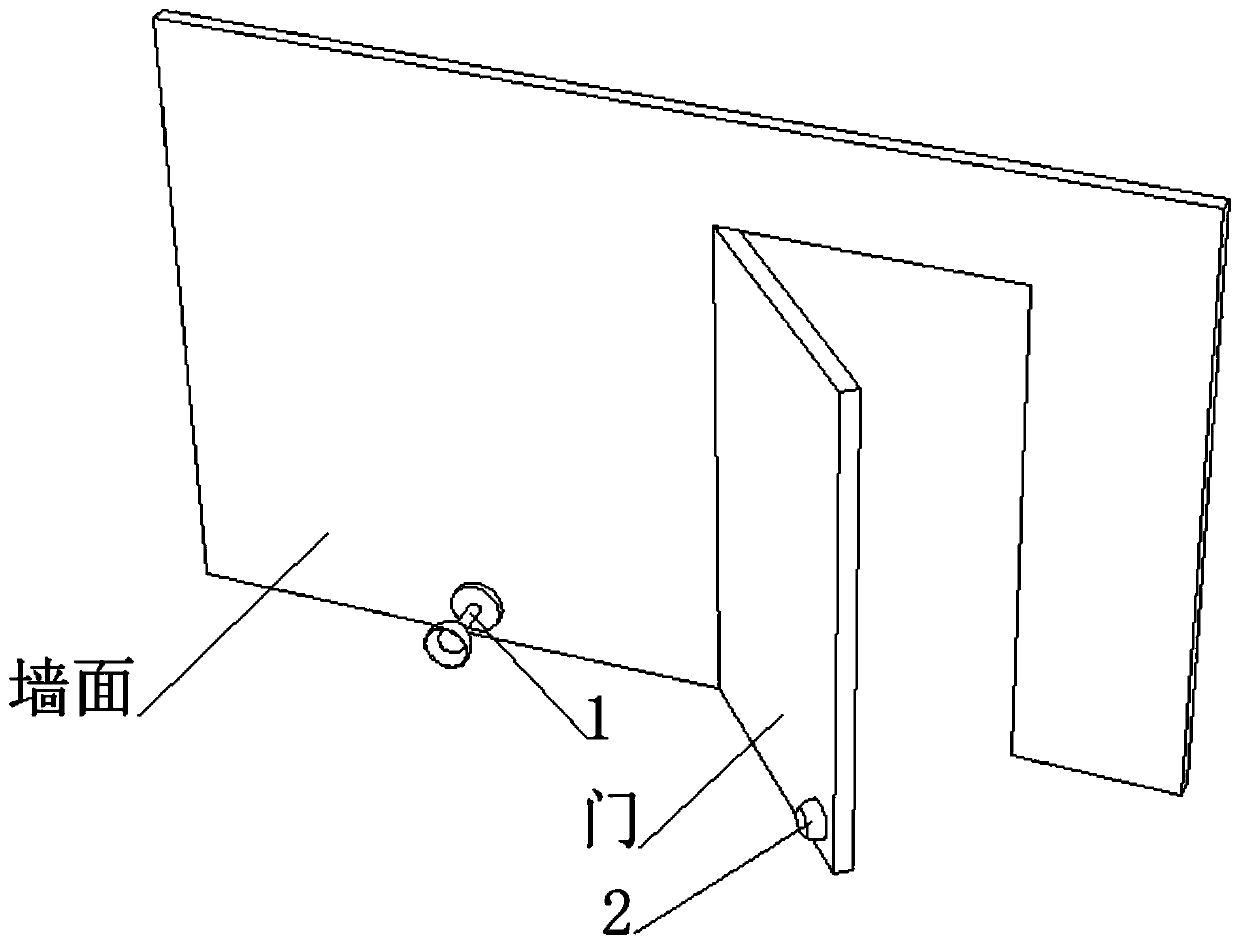

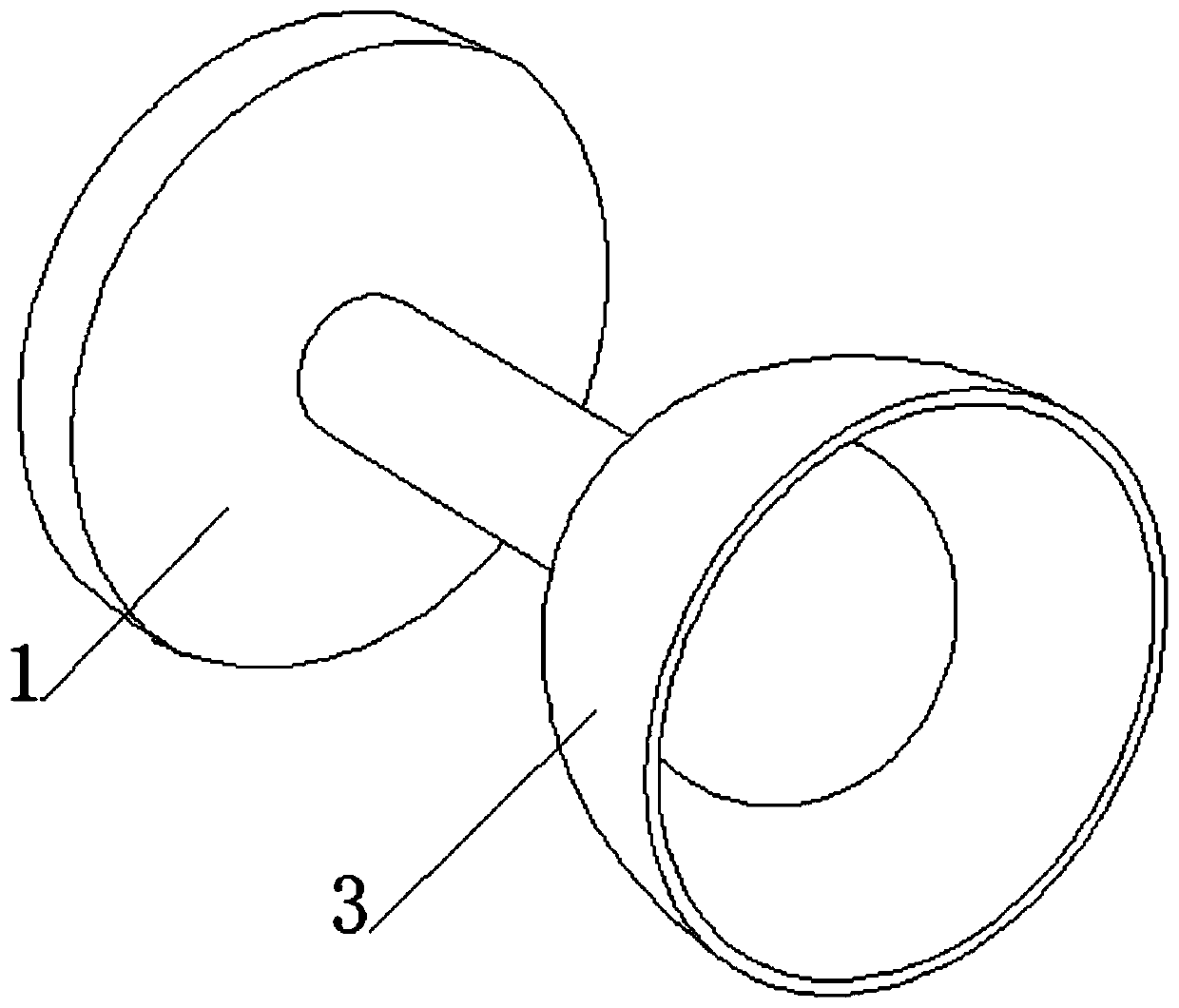

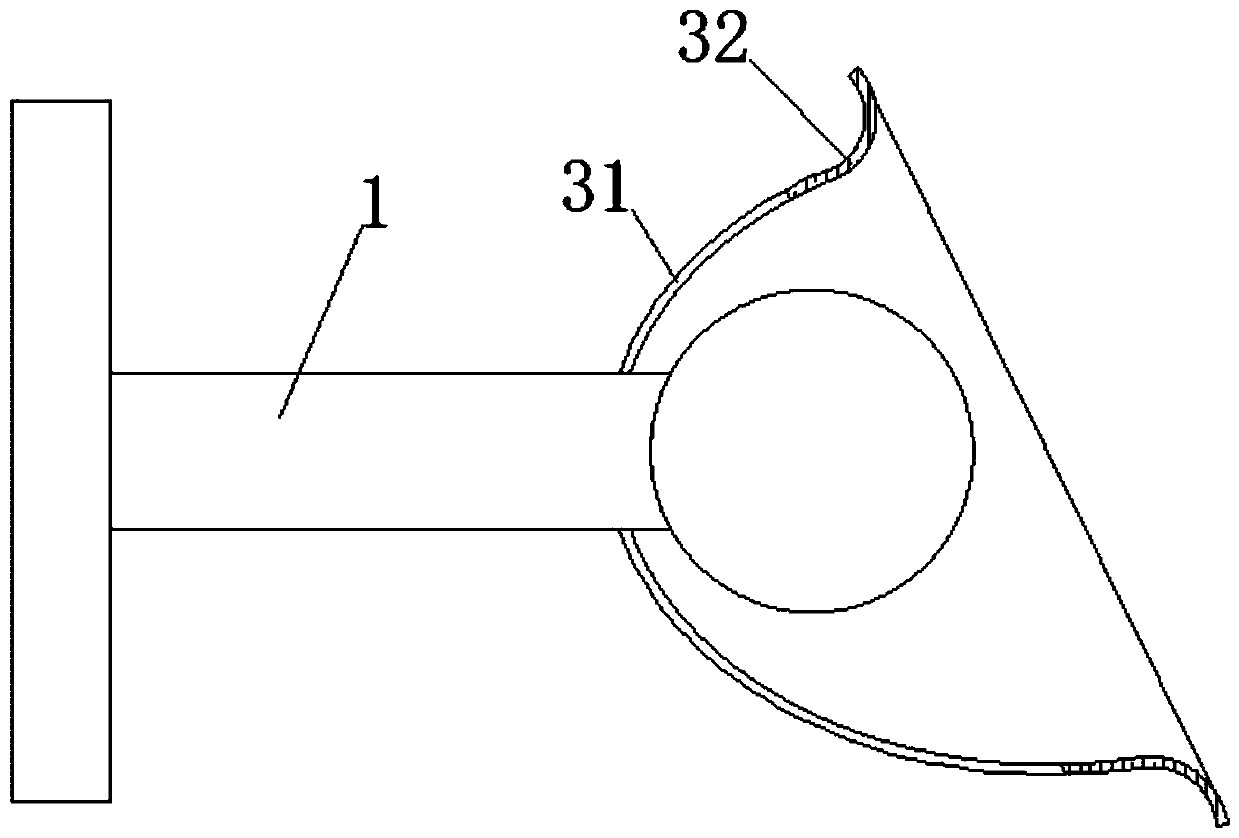

[0045] see Figure 1-3 , a layered pre-drop force door stopper, including a retractable suction head 1 installed on the wall and a built-in base 2 installed on the back of the door, the retracted suction head 1 and the built-in base 2 are matched, and the retracted The outer end of the suction head 1 is fixedly connected with an extension cover 3, the extension cover 3 includes a hard support section 31 and a flange section 32, the hard support section 31 is fixedly connected with the flange section 32, and the hard support section 31 is fixedly connected with the retractable suction head 1 .

[0046] see Figure 5-6 , the inside of the flanging section 32 is excavated with a buffer cavity 4, and the opposite inner walls of the buffer cavity 4 are fixedly connected with a plurality of fixed-point reinforcement blocks 5, and a buffer gap is formed between the ends of the relative multiple fixed-point reinforcement blocks 5 that are close to each other. , it can effectively re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com