Antibacterial composite short fiber and preparation method thereof

A technology of short fiber and production method, which is applied in the field of antibacterial composite short fiber and its preparation, can solve the problems of poor moisture absorption and air permeability, unstable sterilization effect, short bacteriostatic time, etc., and achieves a small amount of re-infiltration and inhibits bacterial growth. , the appearance of less hair effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

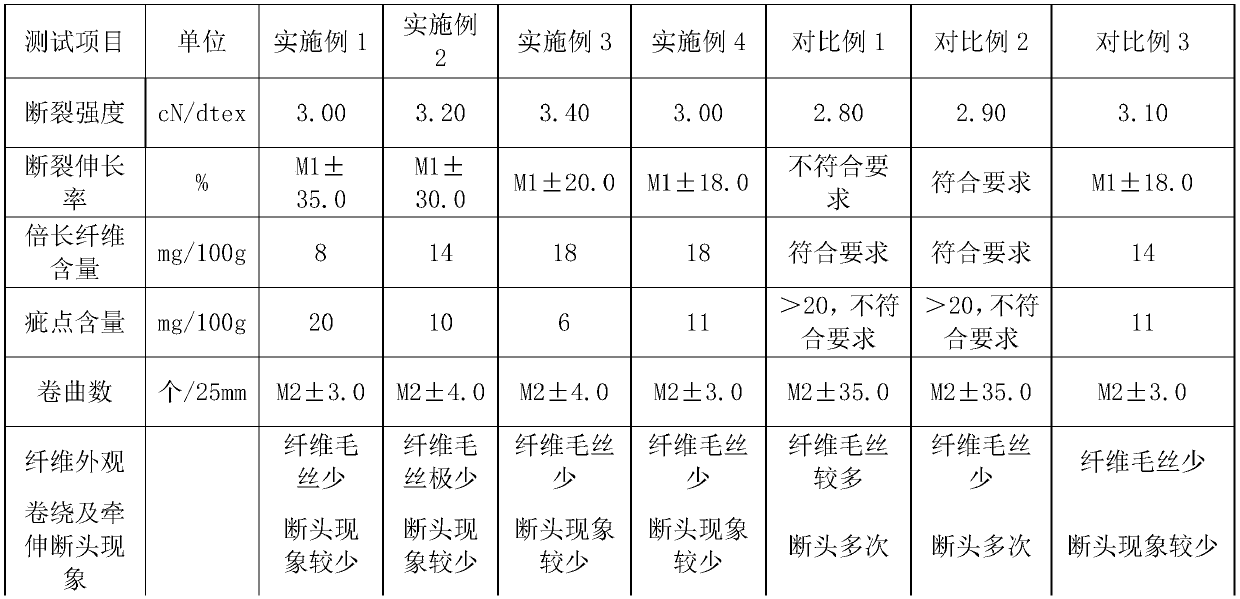

Examples

Embodiment 1

[0030] A preparation method of antibacterial composite staple fiber, comprising the following steps:

[0031] a, the nano-silver of 1 part by weight and the polyethylene particle of 8 parts are mixed uniformly, melted in electric heating pot, then obtain antibacterial polyethylene particle by granulator;

[0032] b. Weigh the following components by weight: 40 parts of polypropylene, 5 parts of ethylene-propylene copolymer, 4 parts of propylene block copolymer, 8 parts of starch-acrylic superabsorbent resin, 2 parts of titanium dioxide, and 4 parts of zinc oxide. ~8 parts, put starch-acrylic superabsorbent resin, titanium dioxide, and zinc oxide into a high-speed pulverizer, then mix them with polypropylene and ethylene-propylene copolymer, and send them into a screw extruder to melt into a polypropylene mixture;

[0033] c. Weigh the following components by weight: 20 parts of linear low density polyethylene, 20 parts of high density polyethylene, 20 parts of antibacterial po...

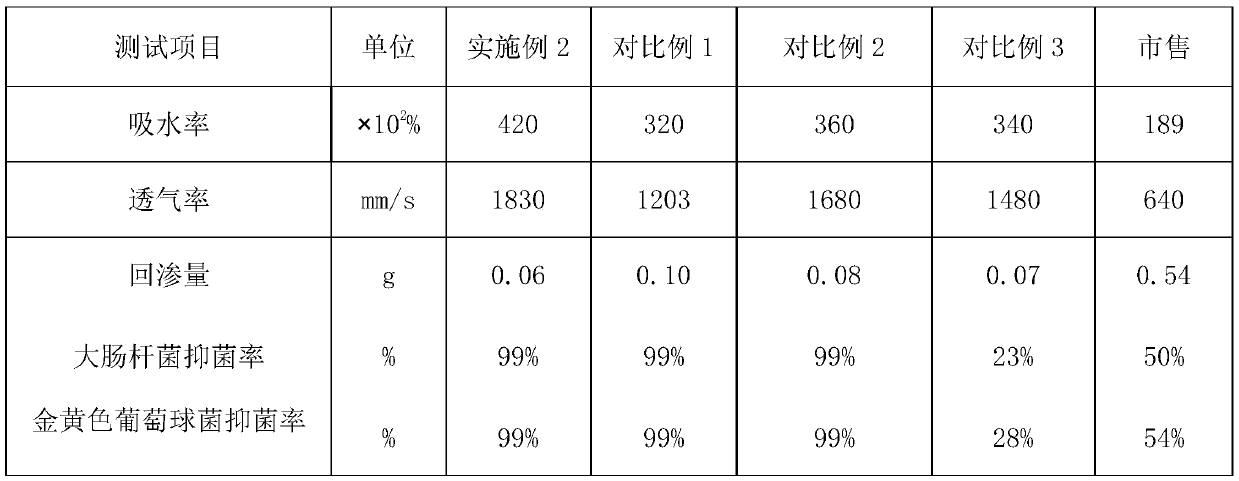

Embodiment 2

[0038] A preparation method of antibacterial composite staple fiber, comprising the following steps:

[0039] a, the nano-silver of 1 part by weight is mixed with 9 parts of polyethylene particles, melted in an electric heating pot, and then the antibacterial polyethylene particles are obtained by a granulator;

[0040] b. Weigh the following components by weight: 42 parts of polypropylene, 6 parts of ethylene-propylene copolymer, 4 parts of propylene block copolymer, 8 parts of starch-acrylic superabsorbent resin, 2 parts of titanium dioxide, 5 parts of zinc oxide Put starch-acrylic superabsorbent resin, titanium dioxide, and zinc oxide into a high-speed pulverizer, mix them with polypropylene and ethylene-propylene copolymer, and send them to a screw extruder to melt into a polypropylene mixture;

[0041] c. Weigh the following components by weight: 24 parts of linear low density polyethylene, 24 parts of high density polyethylene, 22 parts of antibacterial polyethylene part...

Embodiment 3

[0046] A preparation method of antibacterial composite staple fiber, comprising the following steps:

[0047] a, the nano-silver of 1 part by weight is mixed with 10 parts of polyethylene particles, melted in an electric heating pot, and then the antibacterial polyethylene particles are obtained by a granulator;

[0048]b. Weigh the following components by weight: 46 parts of polypropylene, 7 parts of ethylene-propylene copolymer, 5 parts of propylene block copolymer, 9 parts of starch-acrylic superabsorbent resin, 3 parts of titanium dioxide, and 7 parts of zinc oxide Put starch-acrylic superabsorbent resin, titanium dioxide, and zinc oxide into a high-speed pulverizer, mix them with polypropylene and ethylene-propylene copolymer, and send them to a screw extruder to melt into a polypropylene mixture;

[0049] c. Weigh the following components by weight: 28 parts of linear low density polyethylene, 28 parts of high density polyethylene, 25 parts of antibacterial polyethylene ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com