Signal processing method and system for blast furnace lining impact echo detection

A technology of shock echo and blast furnace lining, which is applied in the field of blast furnace smelting, can solve the problems of not considering the elastic wave aliasing effect, large deviation of detection results of blast furnace lining erosion state, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

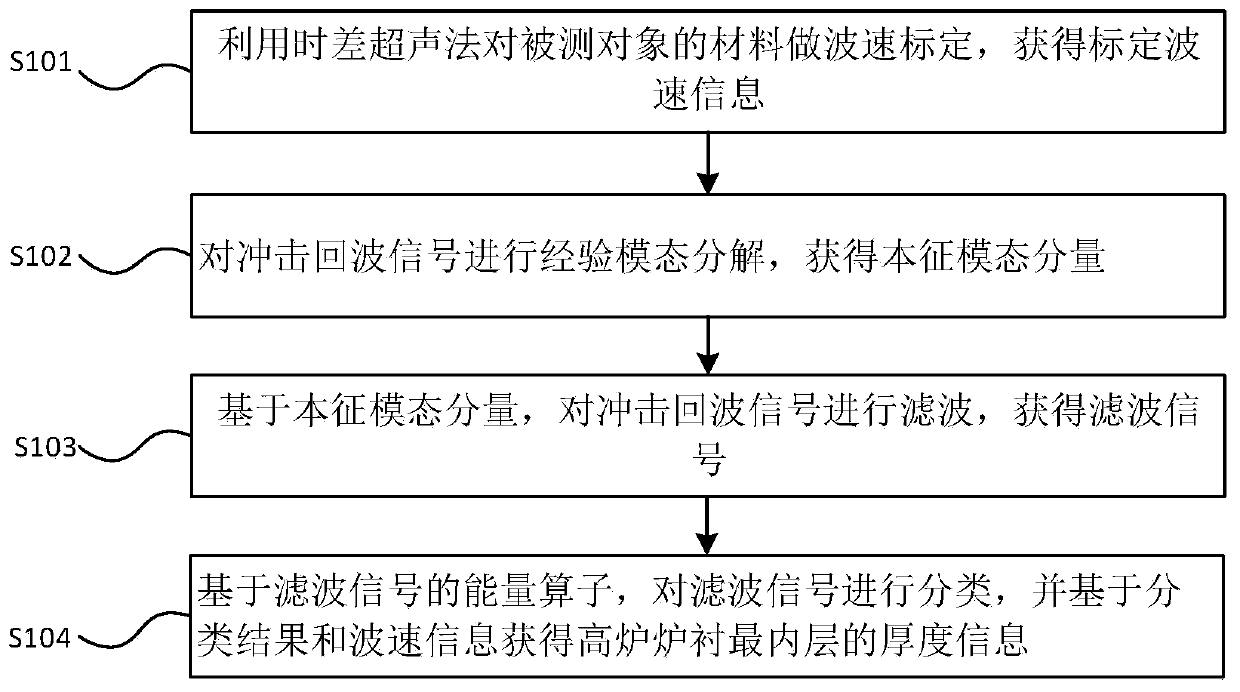

[0056] refer to figure 1 The signal processing method for blast furnace lining shock echo detection provided by Embodiment 1 of the present invention includes:

[0057] Step S101, using the time-of-flight ultrasonic method to calibrate the wave velocity of the material of the measured object, and obtain the calibrated wave velocity information;

[0058] Step S102, performing empirical mode decomposition on the shock echo signal to obtain eigenmode components;

[0059] Step S103, based on the eigenmode component, the shock echo signal is filtered to obtain a filtered signal;

[0060] Step S104, classify the filtered signal based on the energy operator of the filtered signal, and obtain the thickness information of the innermost layer of the blast furnace lining based on the classification result and the wave velocity information.

[0061] The signal processing method for blast furnace lining shock echo detection provided by the embodiment of the present invention uses the tim...

Embodiment 2

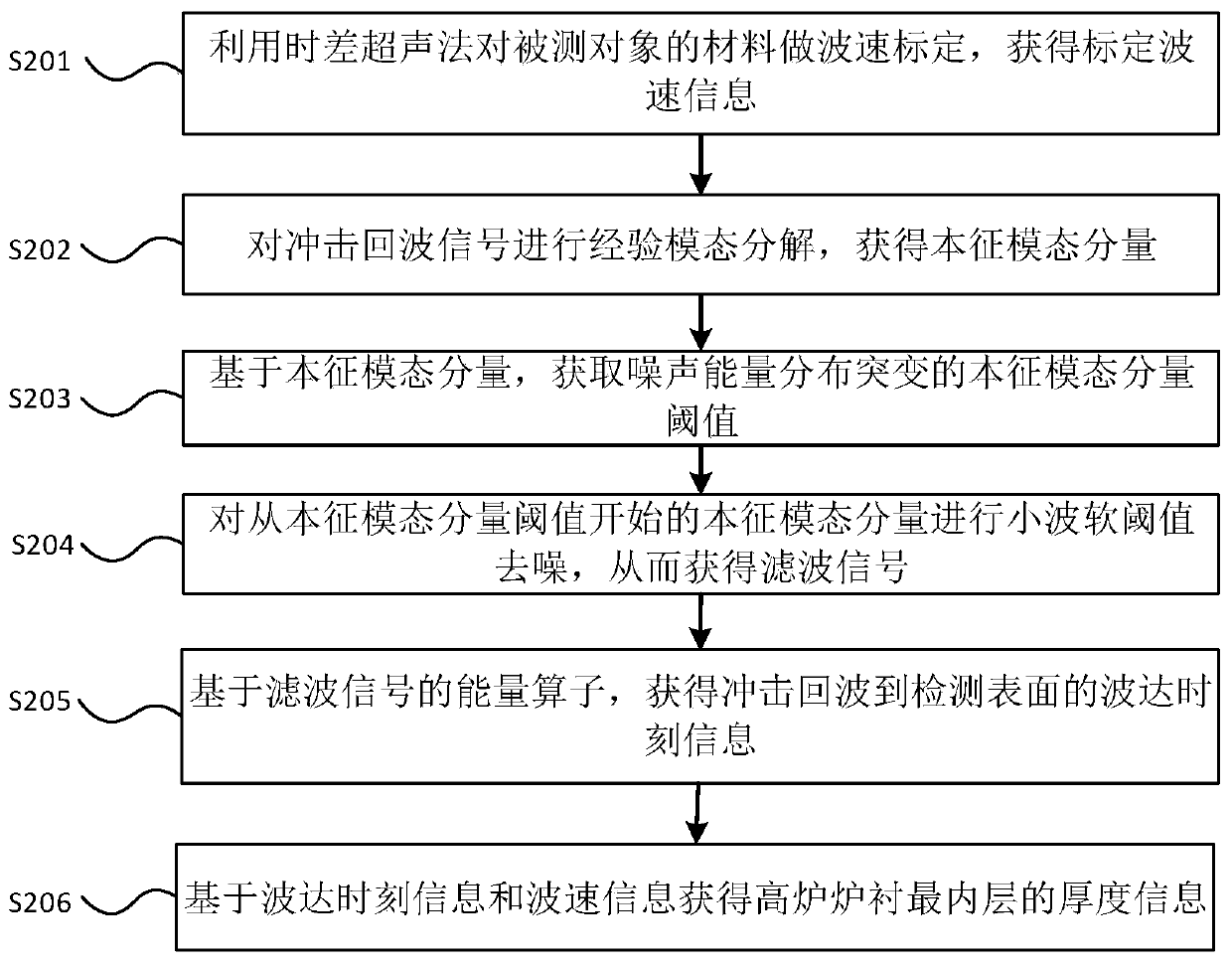

[0064] refer to figure 2 , the signal processing method for blast furnace lining impact echo detection provided by Embodiment 2 of the present invention includes:

[0065] Step S201, using the time-of-flight ultrasonic method to calibrate the wave velocity of the material of the object to be measured, and obtain the calibrated wave velocity information.

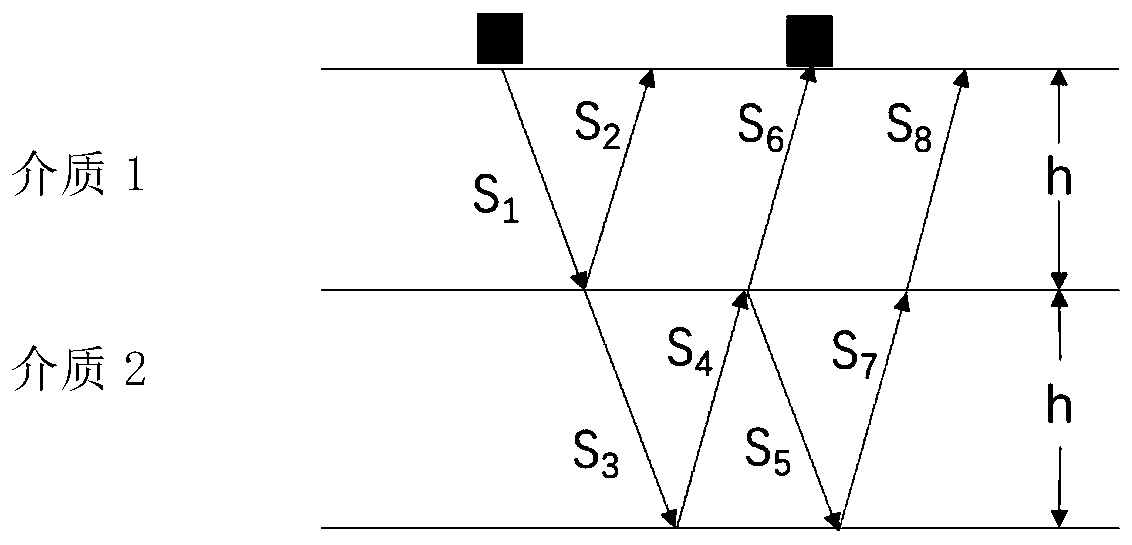

[0066] Specifically, in this embodiment, when the signal processing of blast furnace lining shock echo detection is performed, it is first necessary to study the propagation mode of waves in solids. The essence of using shock echo to measure thickness is calculated by using the characteristic frequency corresponding to the interface between the measured object and the environment and the propagation velocity of the shock wave in the measured object. And because the shock wave is reflected and transmitted at the heterogeneous interface of a heterogeneous medium such as a steel-concrete structure or a carbon-concrete structur...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com