Method for producing adiponitrile

A technology of adiponitrile and adipic acid, applied in the field of chemical product synthesis, can solve the problems of long reaction residence time, unfavorable continuous reaction process, etc., and achieve the effects of easy industrialization, high safety and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

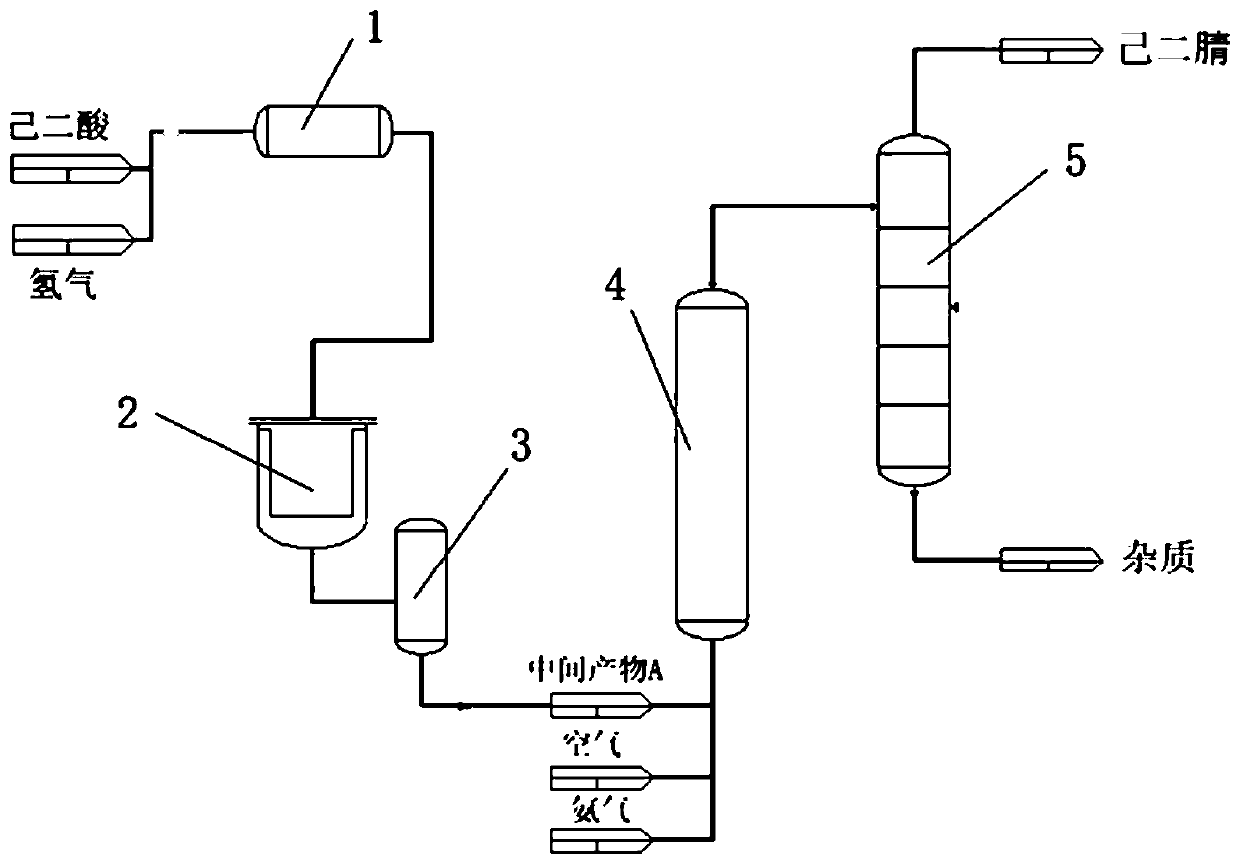

Image

Examples

Embodiment 1

[0027] Use low hydrogen 5% (mole ratio, the remaining 95% is nitrogen), reduce the Ru / activated carbon catalyst at normal pressure in the pipeline reactor, the reduction temperature is 500°C, the reduction time is 10h, and the volume space velocity during reduction is 8000h -1 ·ml / gcat. Adipic acid uses 1 times the number of moles of methanol as a solvent, the reaction pressure is 5MPa, the reaction temperature is 200°C, and the feed space velocity is 5h -1 ·ml / gcat, the molar amount of hydrogen continuously fed is 10 times that of adipic acid, the reaction products are all liquid, the output rate control is consistent with the feed, and the product and a small amount of catalyst that may be brought out are separated in the filter to achieve solid-liquid separation . The intermediate product A (including a mixture of hexanediol and a small amount of 6-hydroxyl-1-hexanal and methanol) generated by the first step reaction is gaseous at 200 degrees under normal pressure (contain...

Embodiment 2

[0029] Use low hydrogen 5% (mole ratio, the remaining 95% is nitrogen), reduce the Ru / activated carbon catalyst at normal pressure in the pipeline reactor, the reduction temperature is 500°C, the reduction time is 10h, and the volume space velocity during reduction is 8000h -1 ·ml / gcat. Adipic acid uses 1 times the number of moles of methanol as a solvent, the reaction pressure is 5MPa, the reaction temperature is 200°C, and the feed space velocity is 30h -1 ·ml / gcat, the molar amount of hydrogen continuously fed is 10 times that of adipic acid, the reaction products are all liquid, the output rate control is consistent with the feed, and the product and a small amount of catalyst that may be brought out are separated in the filter to achieve solid-liquid separation . The intermediate product A (comprising a small amount of hexanediol, a large amount of adipaldehyde, 6-hydroxyl-1-hexanal, and methanol) produced by the first step reaction is gaseous at 200 degrees under normal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com