Magnetic control nano-forming micromechanical device and three-dimensional fiber forming method

A nano-forming and micro-mechanical technology, applied in the field of spinning and forming, can solve the problems of messy fiber arrangement, long time-consuming, high conductivity of polymer solution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

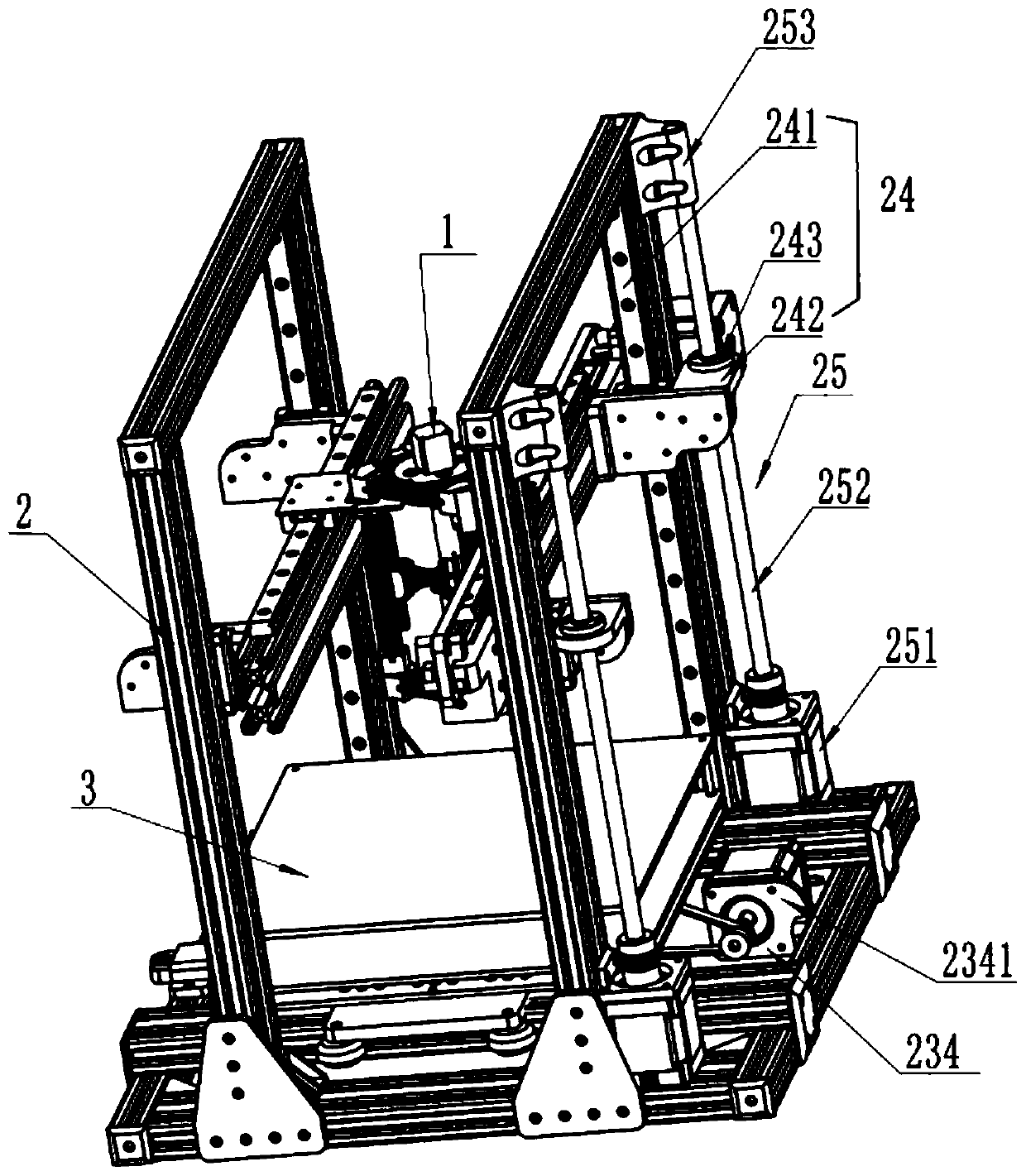

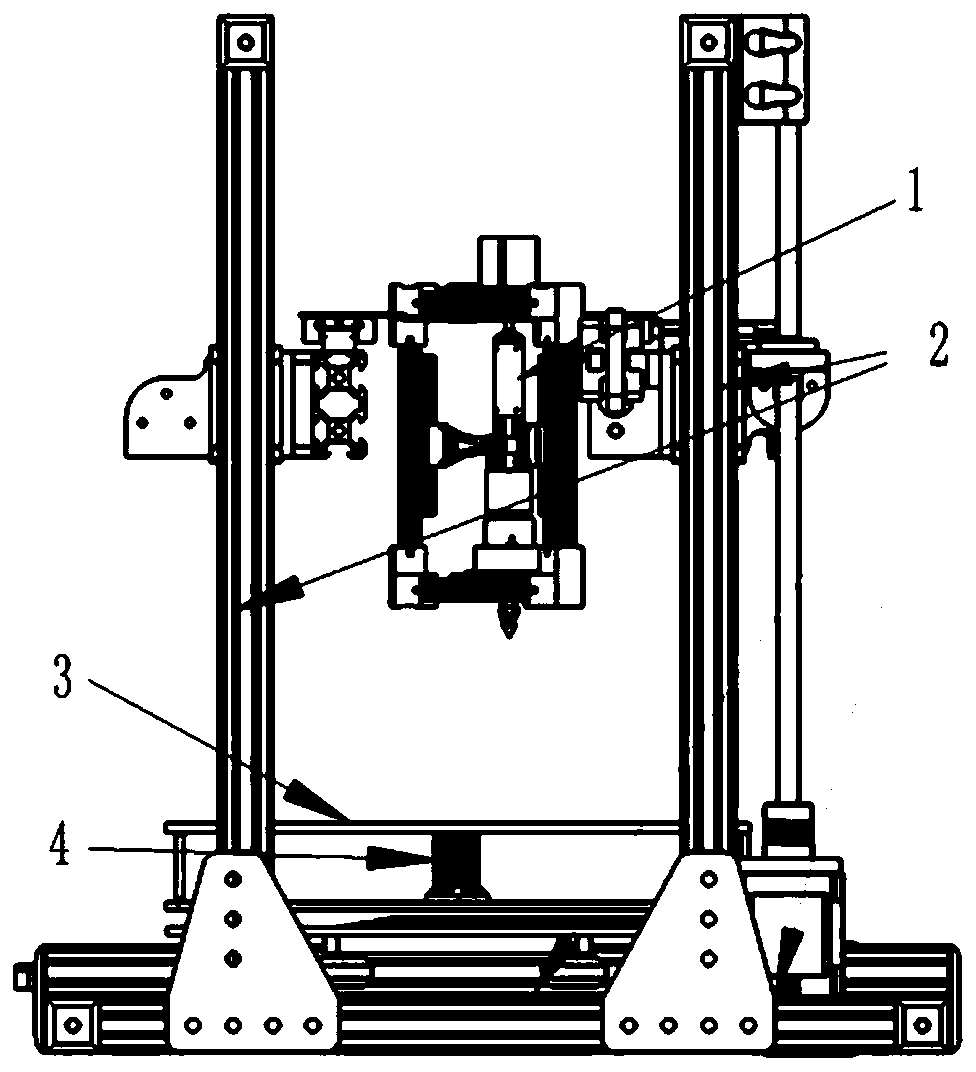

[0056] Based on the characteristics of magnetic fluid, this embodiment provides a magnetically controlled nano-molded micromechanical device, such as figure 1 and figure 2 As shown, it includes a magnetic fluid preparation device 1 for generating magnetic fluid, a three-dimensional control nano-table 2 for fixing the magnetic fluid preparation device, a working platform 3 below the magnetic fluid preparation device and a strong magnet 4 below the working platform . The present embodiment strong magnet adopts neodymium iron boron strong magnet.

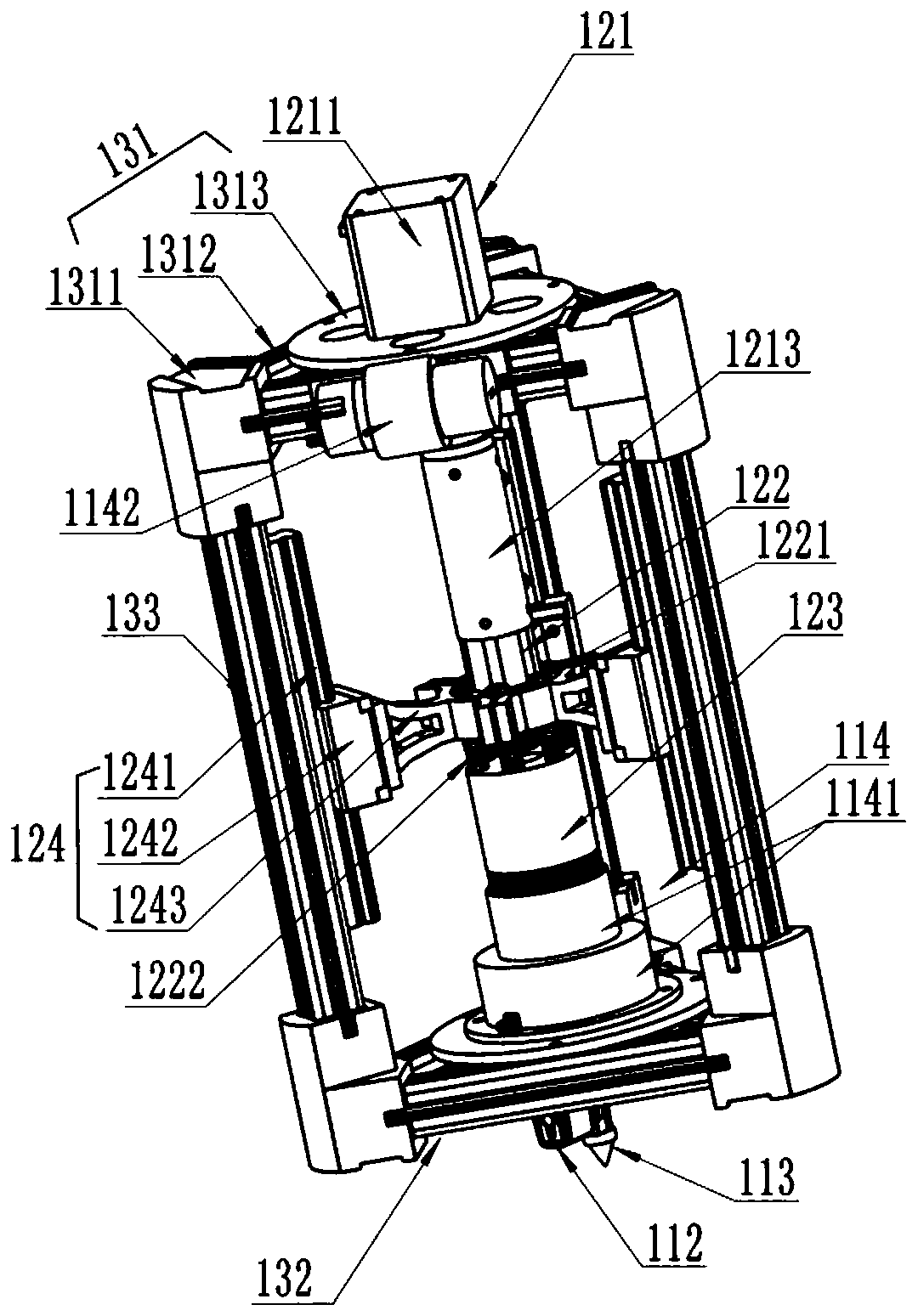

[0057] Such as image 3 and Figure 4 As shown, the magnetic fluid preparation device 1 used in this embodiment includes a magnetic fluid generating mechanism 11 , a pushing mechanism 12 and a fixing mechanism 13 . The magnetic fluid generating mechanism 11 includes a container chamber 111, a nozzle 113 configured with a solenoid valve 112 is installed at the liquid outlet position of the container chamber, and the container chamb...

Embodiment 2

[0081] This embodiment provides another spinning three-dimensional molding method. The spinning raw material for this example is obtained by uniformly mixing citrate-stabilized magnetic nanoparticle dispersion and polyethylene oxide (PEO) solution with a concentration of 14 wt% in a volume ratio of 1:1.

[0082] Magnetic nanoparticles are prepared by conventional co-precipitation method (see A.Tokarev, W.–k., I.Sevonkaev, D.Goia, K.G.Kornev, Soft Matter 2014,10,1917, etc.). During the synthesis process, under stirring conditions, 1.625g (8mmol) FeCl 2 4H 2 O and 4.43g (16mmol) FeCl 3 ·6H 2 O was dissolved in 190 mL of water. 10 mL of aqueous ammonia at a concentration of 25 wt% was added to the solution, which resulted in the formation of a black magnetite precipitate. After stirring for 10 minutes, the precipitate was magnetically separated from the solution, and the precipitate was washed three times with deionized (DI) water to obtain magnetic nanoparticles.

[0083] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com