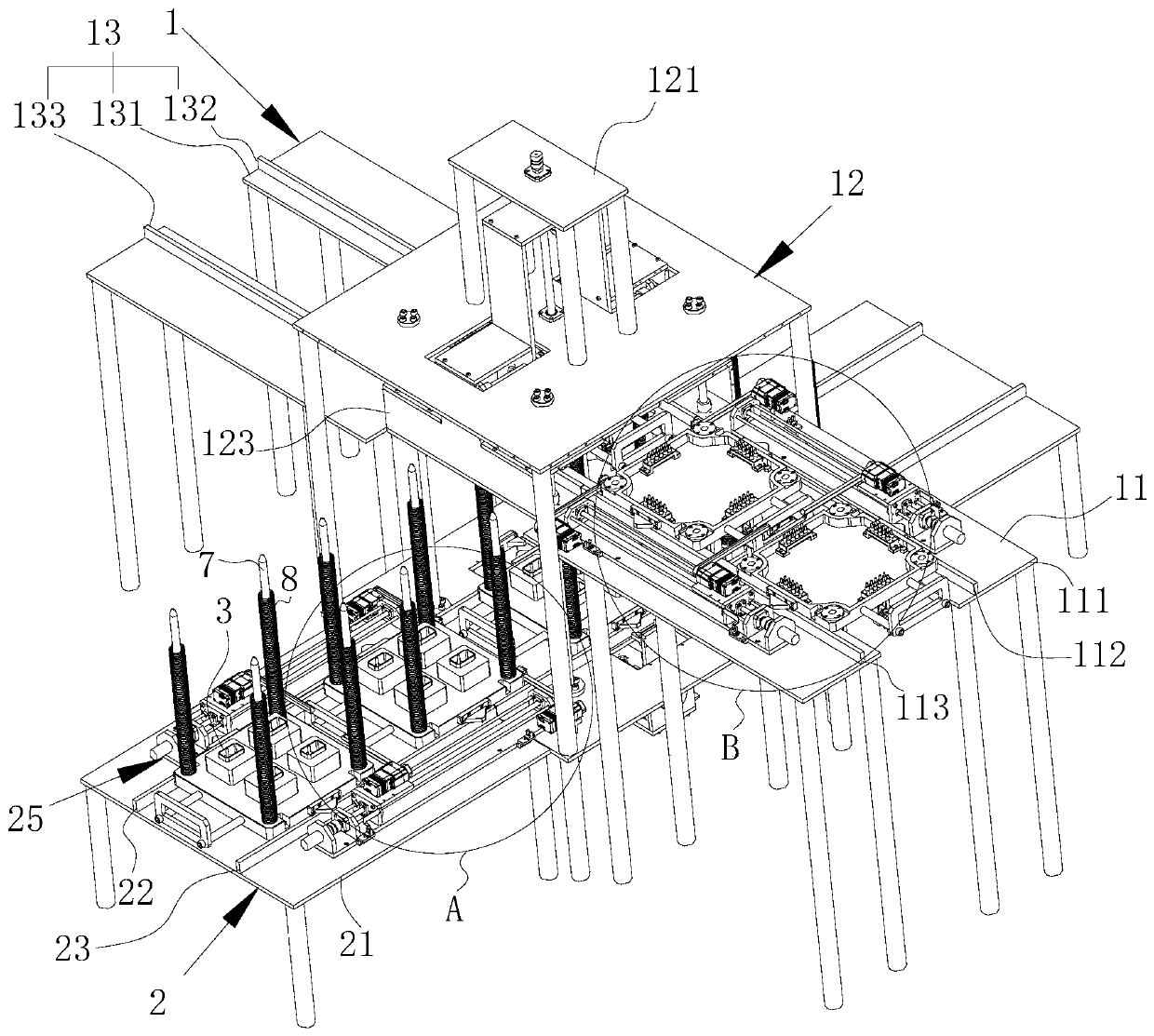

Automatic production device and system

A production device and driving device technology, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of high cost and complicated process of automatic production equipment, and achieve the effect of simplifying processing steps, ensuring continuity and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

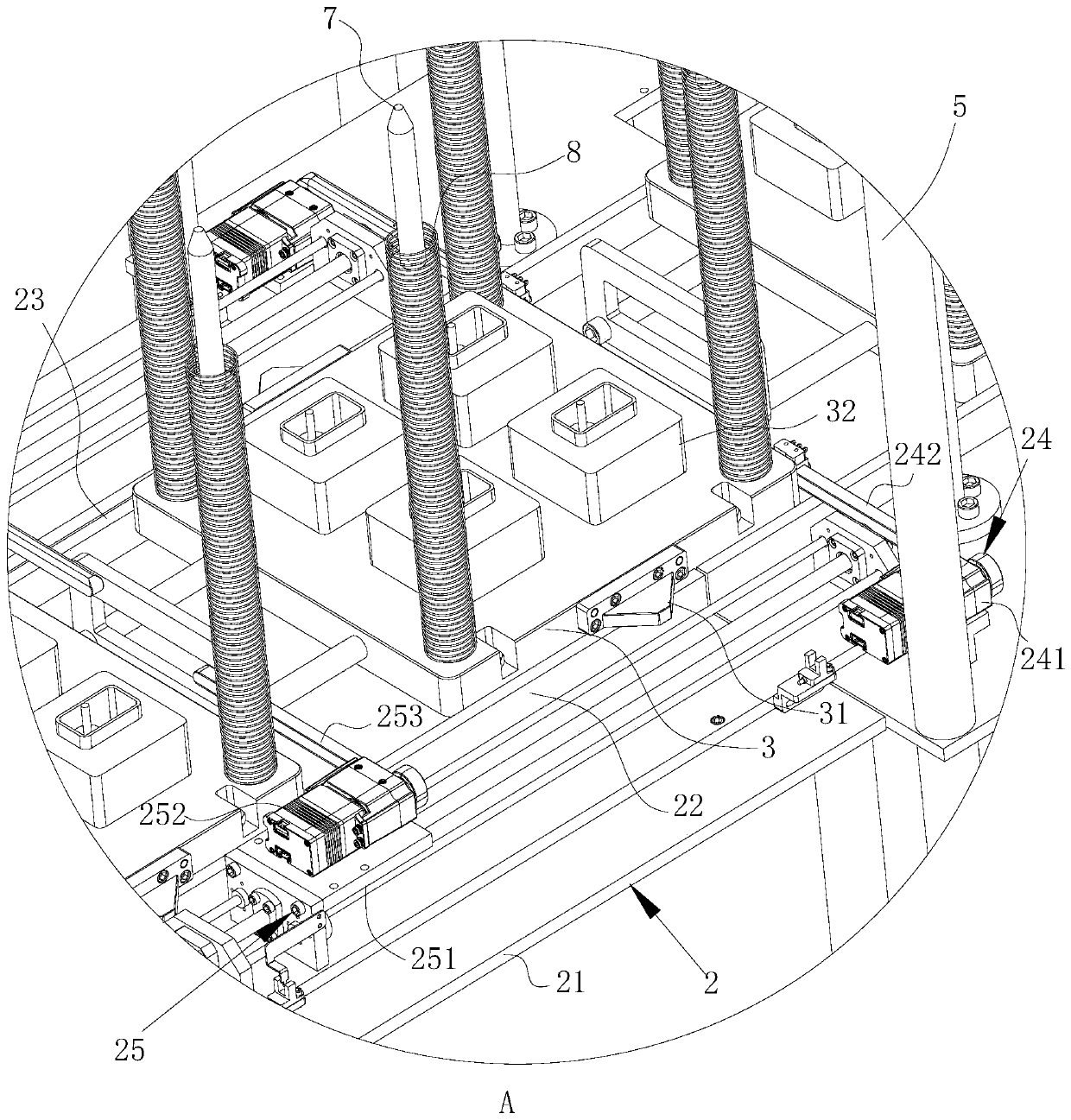

Method used

Image

Examples

specific Embodiment approach

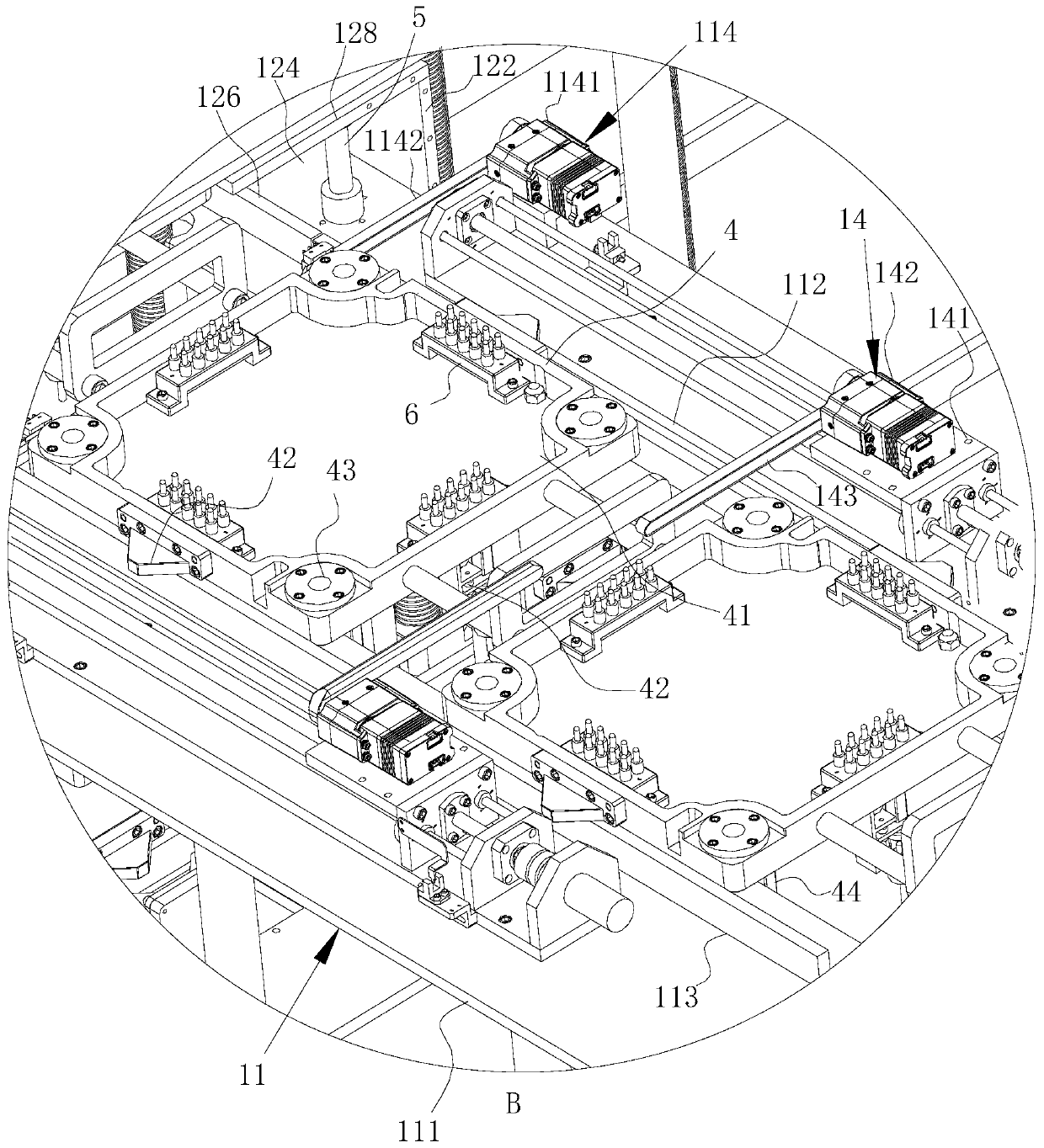

[0046] Further, see Figure 4 and Figure 5 , as a specific embodiment of an automated production device provided by the present invention, the lower assembly line 2 further includes a first clamping mechanism 9, and the first clamping mechanism 9 is arranged in the area where the pressing device 12 is facing the lower assembly line 2 , the first clamping mechanism 9 includes a first clamping plate 91 and a first clamping drive mechanism 92, the first clamping drive mechanism 92 is fixed on the first placement plate 21, two first clamping plates 91 are oppositely arranged and connected to the second On the output shaft of a clamping driving mechanism 92 , the first clamping driving mechanism 92 is used to drive the first clamping plate 91 to clamp or loosen the first carrier 3 .

[0047] The first clamping mechanism 9 makes it difficult for the first carrier 3 located in the area where the pressing device 12 is facing the lower assembly line 2 to move during processing.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com