Preparation method and purpose of chitosan-Zn compound nano-particle preservative film

A nanoparticle and chitosan technology, which is applied in the preservation of fruits and vegetables, and the preservation and application of food ingredients as antimicrobials, can solve the problems of cumbersome extraction process of natural extracts and poor freshness preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

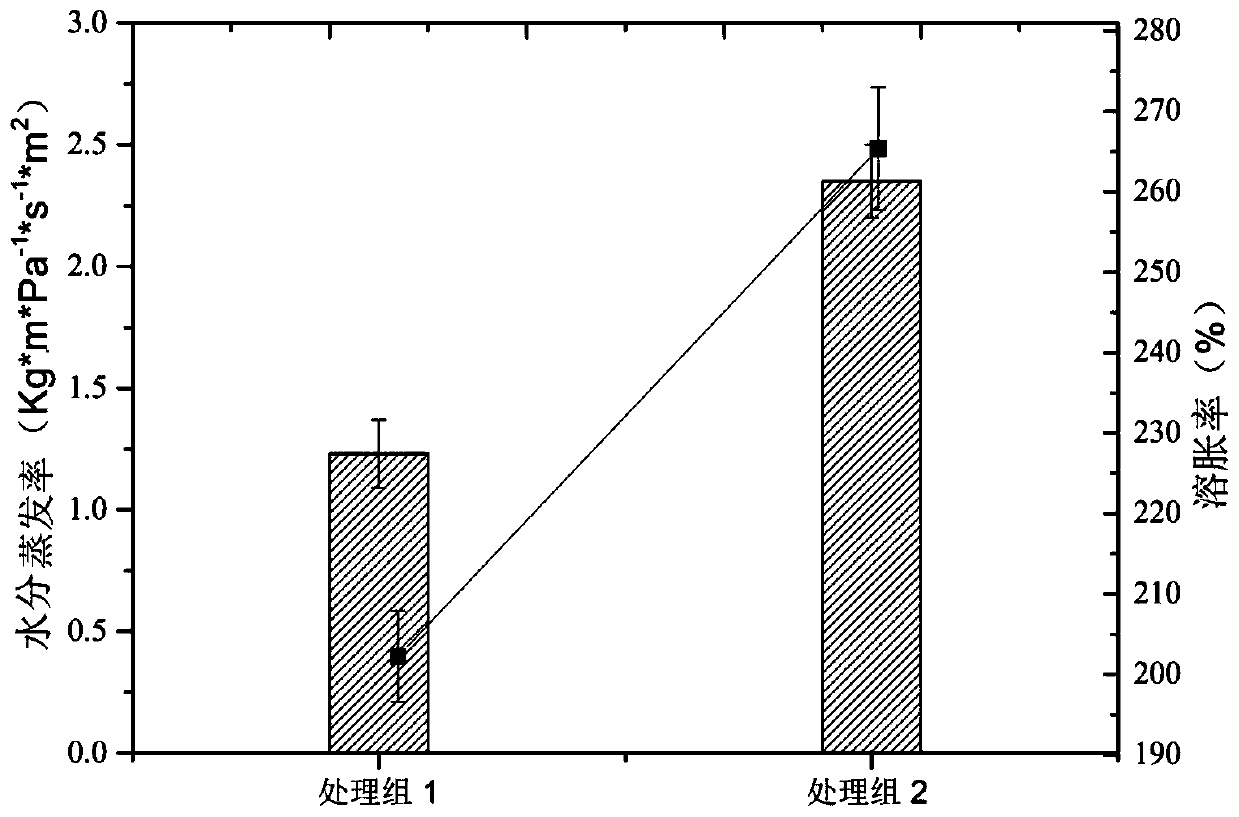

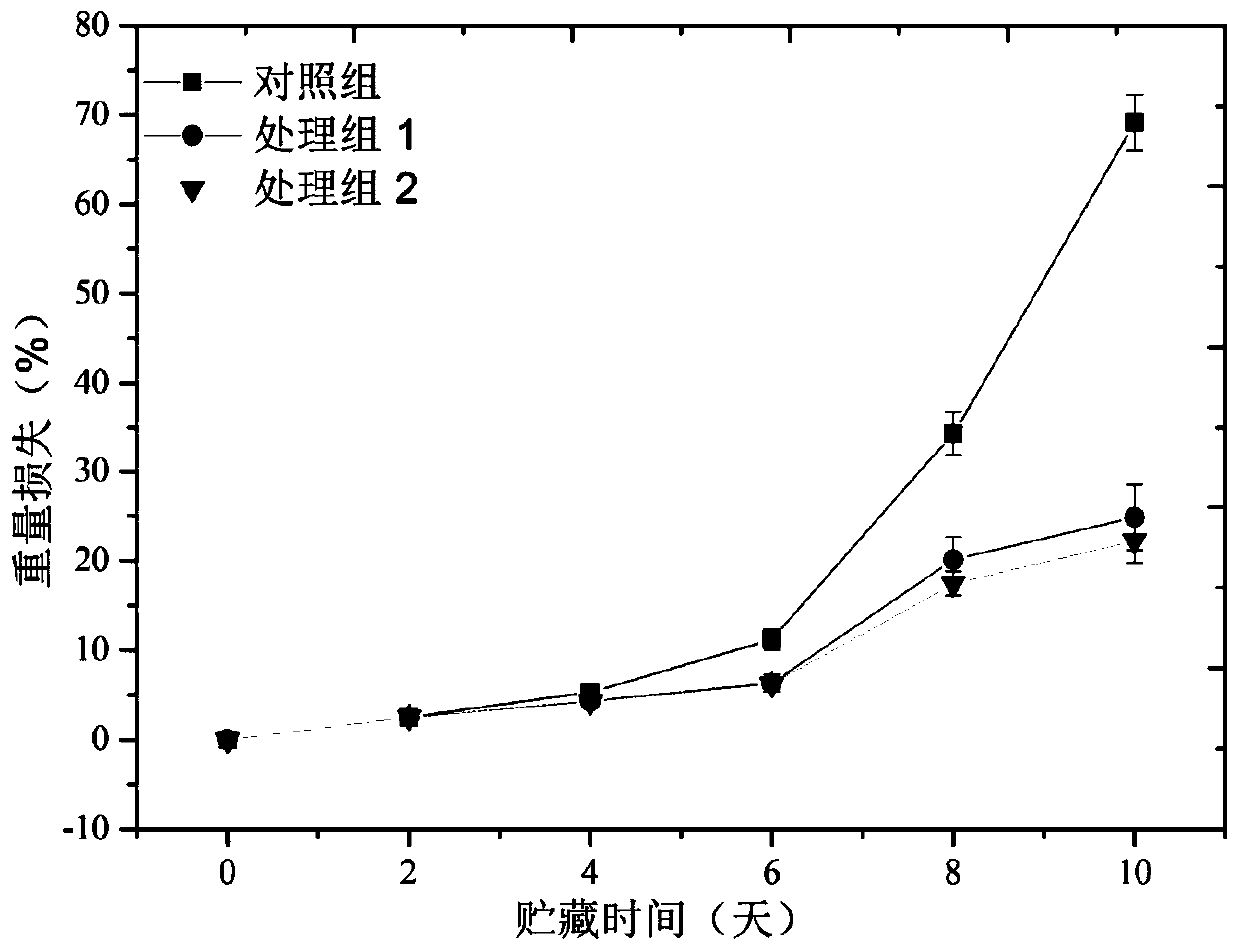

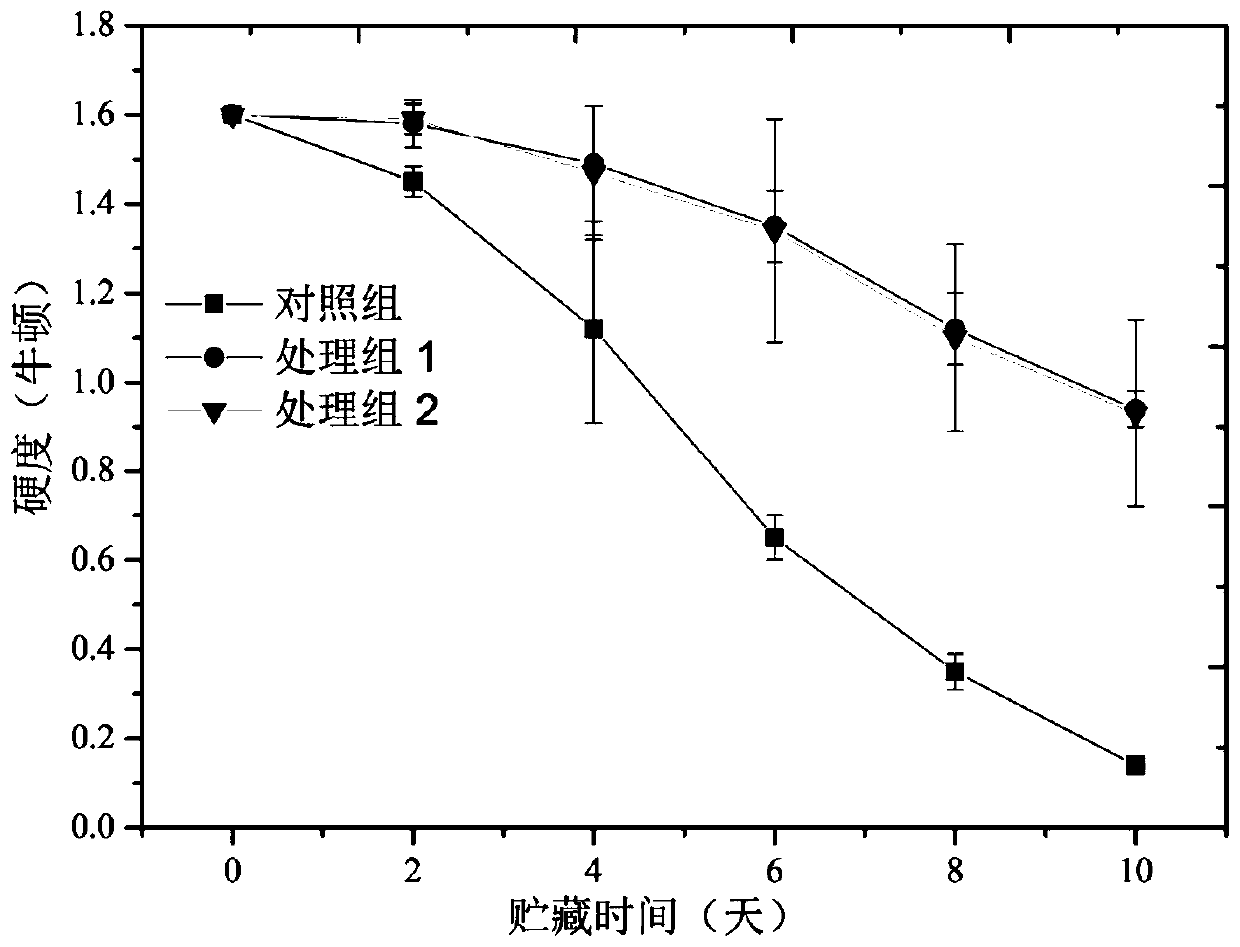

[0032] Concerning the shortcomings of the prior art and packaging fresh-keeping materials that have appeared on the market, the inventors of the present application have invented a chitosan-Zn composite nanoparticle fresh-keeping film and its preparation method and application after in-depth research. The antibacterial property of chitosan is relevant to its molecular weight and degree of deacetylation etc., so the fresh-keeping film of the present invention uses low molecular weight chitosan and Zn 2+ The composite nanoparticles, and in order to improve the adhesion performance of the plastic wrap, a certain amount of starch is added to the film substrate. The preparation method of chitosan-Zn composite nano particle preservative film of the present invention comprises: 1) prepare chitosan-Zn composite nano particle solution by ion cross-linking method; 2) prepare nanocrystalline cellulose, 3) step 1) The prepared chitosan-Zn composite nanoparticle solution, the nanocrystalli...

Embodiment 1

[0062] 1) Preparation of chitosan-Zn composite nanoparticle cling film

[0063] 1.1) Preparation of chitosan-Zn composite nanoparticles solution

[0064] β-chitosan was depolymerized by cellulase (3%, w / w) at 55°C for 7h to prepare low molecular weight chitosan (80kDa, measured by laser dynamic particle size analyzer)

[0065] Dissolve 6g of low-molecular-weight chitosan in 100mL of distilled water, adjust the pH to 4.5, at room temperature, under nitrogen protection, under the condition of electromagnetic stirring and avoiding light, slowly add 10mL of 0.1mol / L zinc acetate dropwise, precipitation occurs, react for 1h, and statically place, filter, wash and dry to obtain a deep reddish brown product, i.e. chitosan-Zn composite nanoparticles;

[0066] Weigh 25 mg of chitosan-Zn composite nanoparticles and dissolve in 100 mL of 1% acetic acid solution, and adjust the pH of the solution containing chitosan-Zn composite nanoparticles to about 4.6-4.7. Then 0.25 mg / mL sodium tri...

Embodiment 2

[0095] 1) Preparation of chitosan-Zn composite nanoparticle cling film

[0096] 1.1) Preparation of low molecular weight chitosan-Zn composite nanoparticles solution

[0097] The above chitosan was depolymerized by cellulase (3%, w / w) at 55° C. for 7 h to prepare low molecular weight chitosan (80 kDa, measured by a laser dynamic particle size analyzer).

[0098] Dissolve 6g of low-molecular-weight chitosan in 100mL of distilled water, adjust the pH to 4.5, at room temperature, under nitrogen protection, under the condition of electromagnetic stirring and avoiding light, slowly add 10mL of 0.1mol / L zinc acetate dropwise, precipitation occurs, react for 1h, and statically Set, filter, wash and dry dark reddish brown product, that is, low molecular weight chitosan-Zn composite nanoparticles;

[0099] Weigh 25 mg of low molecular weight chitosan-Zn composite nanoparticles and dissolve in 100 mL of 1% acetic acid solution, adjust the pH of the chitosan-Zn composite nanoparticle so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com