A method of underground excavation construction of assembled corrugated steel plate underground comprehensive pipe gallery

A technology of integrated pipe gallery and corrugated steel plate, applied in earthwork drilling, shaft equipment, mining equipment, etc., can solve the problems of affecting urban traffic, increasing construction time, and large construction cost, saving construction steps and preventing wells. Wall collapse, easy disassembly effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

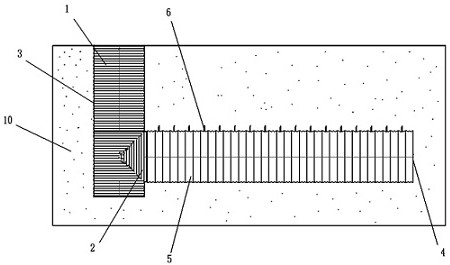

[0030] The main body of the comprehensive pipe gallery of the present invention is composed of a vertical shaft 3 and a horizontal pipe gallery 4 with a length of several meters. The construction method of the present invention has been successfully implemented in engineering.

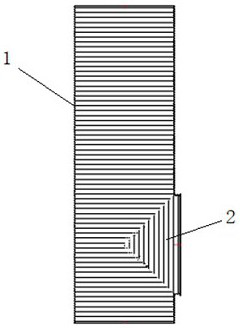

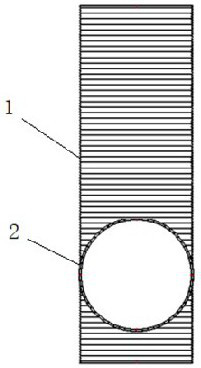

[0031] figure 1 , 2 It shows that the upper port of the shaft spiral corrugated pipe 1 is welded with four reinforcement rings for hoisting, the lower part of the shaft spiral corrugated pipe 1 is connected with the spiral corrugated pipe tee 2, and the diameter of the spiral corrugated pipe tee 2 is the same as that of the horizontal pipe gallery 4 Matching, there is a connection hole on the lower side of the shaft spiral corrugated pipe 1, the rear end of the spiral corrugated pipe tee 2 is welded to the connection hole of the shaft spiral corrugated pipe 1, and the front end of the spiral corrugated pipe tee 2 is welded with a connecting horizontal pipe The flange of the assembled corrugated steel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com