Double-station cast tube surface zinc spraying machine

A double-station, casting tube technology, applied in the direction of fusion spraying, metal material coating process, coating, etc., can solve the problems of prone to failure, radial deviation, and jamming of the pushing and rotating mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0112] The present invention will be further described in detail with reference to the accompanying drawings and embodiments. The following embodiments are for explaining the present invention and the present invention is not limited to the following embodiments.

[0113] Examples.

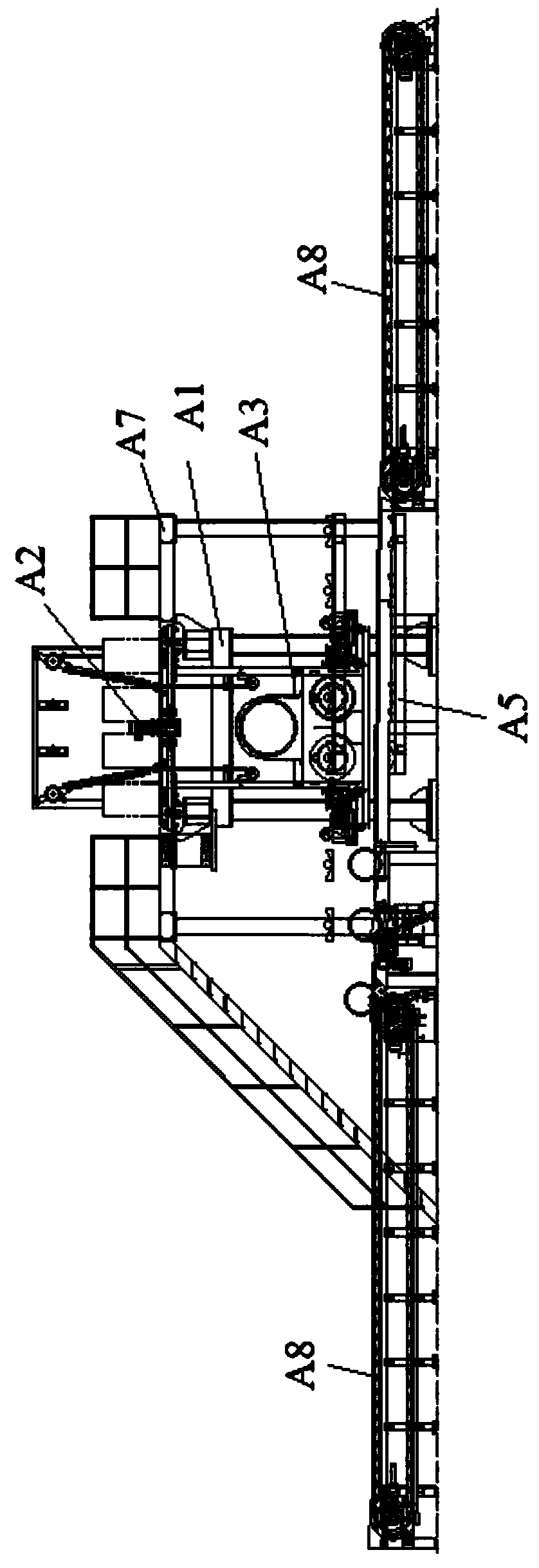

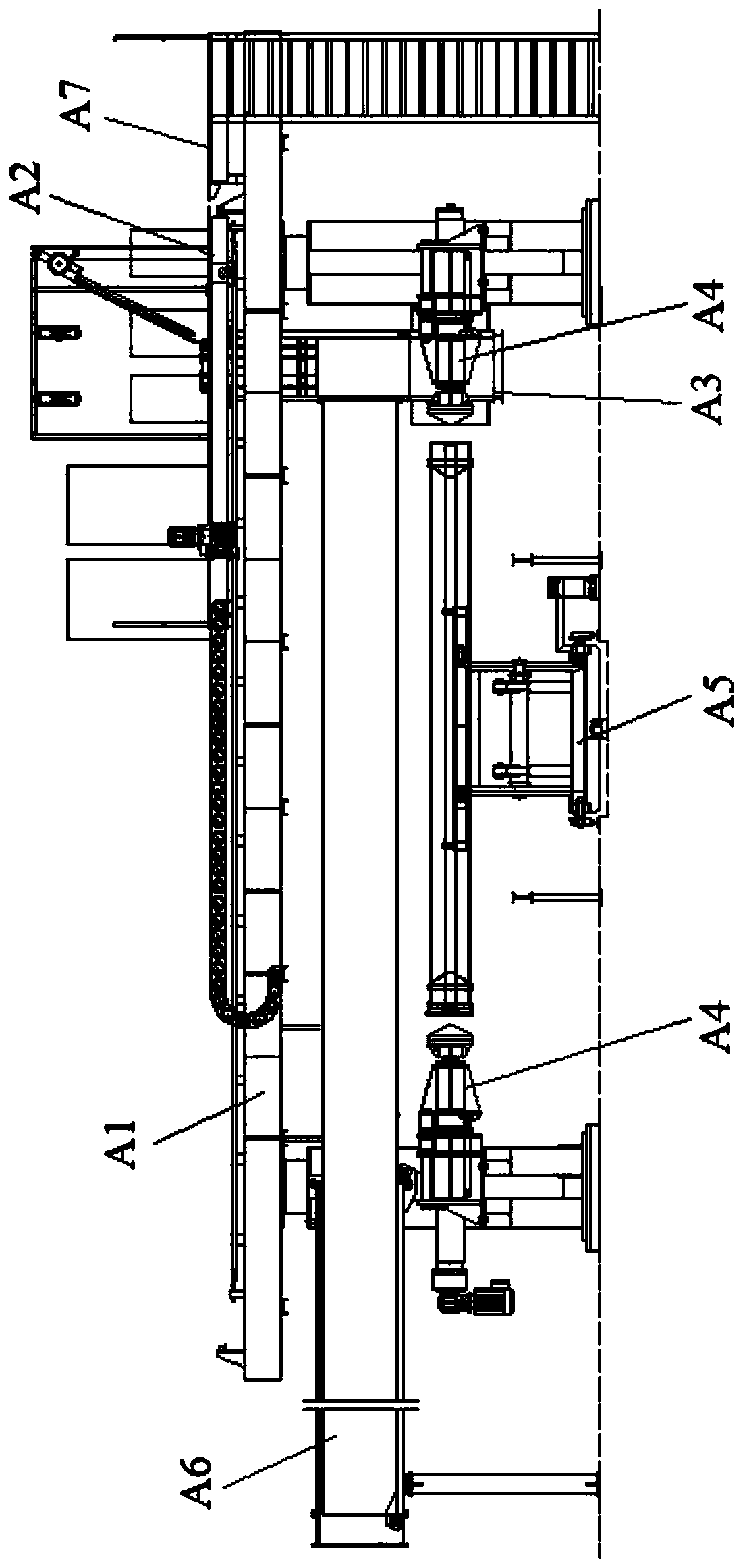

[0114] See Figure 1 to Figure 47 .

[0115] This embodiment discloses a double-station cast pipe surface zinc spraying machine, which includes a frame A1, a zinc spraying trolley A2, a wire feed adjustment device A3, two sets of pushing and rotating mechanisms A4, a casting pipe loading and unloading mechanism A5, and dust removal Device A6, zinc sprayer working platform A7 and conveyor chain mechanism A8.

[0116] The top of the frame A1 is provided with a rail A1-1 for the zinc spray cart, and the zinc spray cart A2 is installed on the frame A1 and moves laterally along the rail A1-1 for the zinc spray cart. The wire feeding adjusting device A3 is arranged under the zinc spraying trolley A2 and connec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com