A kind of 3,3'-diaminodiphenyl sulfone continuous synthesis method

A technology of diaminodiphenylsulfone and dinitrodiphenylsulfone, which is applied in the field of fine chemicals, can solve the problems of not meeting the requirements of aviation composite materials, unfavorable large-scale production, and low yield, and achieves easy washing, filtration and product separation , improve production capacity and equipment utilization, and overcome the effect of excessive iron ions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

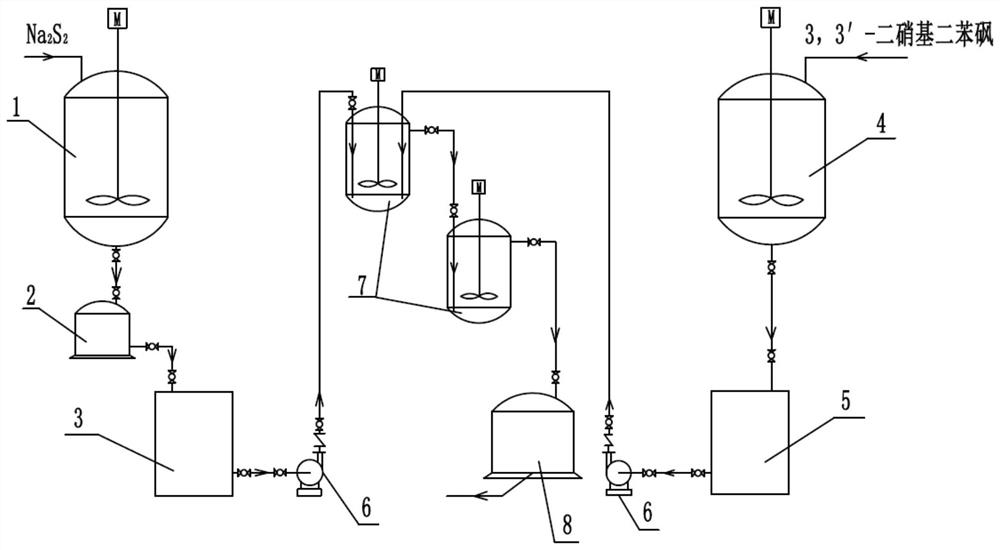

Method used

Image

Examples

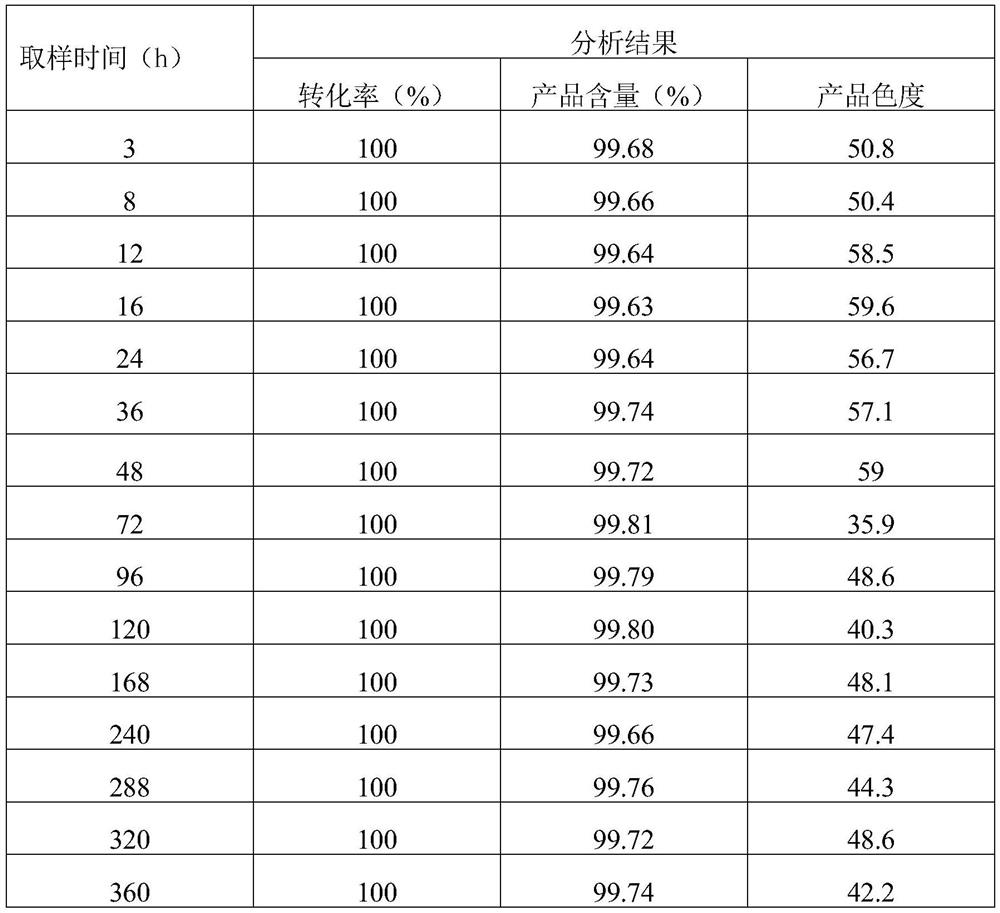

Embodiment 1

[0030] Preparation of sodium disulfide reducing solution:

[0031] first to 5m 3 Add 3.4m 3of water, start stirring, and 1300kg of sodium sulfide (mass content is 60%) is added in batches in the first raw material preparation still, and then in the first raw material preparation still, add the solid sulfur of 310kg, in order to prevent the reaction system from generating The highly toxic hydrogen sulfide gas overflows and hurts employees. The system uses the induced draft fan to maintain a slight negative pressure in the first raw material preparation kettle, and at the same time the gas discharged by the induced draft fan is absorbed by spraying sodium hydroxide solution. The tail gas produced by the reaction is absorbed by the lye. The first raw material preparation kettle is slowly heated to 90°C, after the sodium sulfide and sulfur are completely dissolved, continue to keep warm for 1 hour, then cool the reaction system to 75°C, filter through the filter 2 while it is ho...

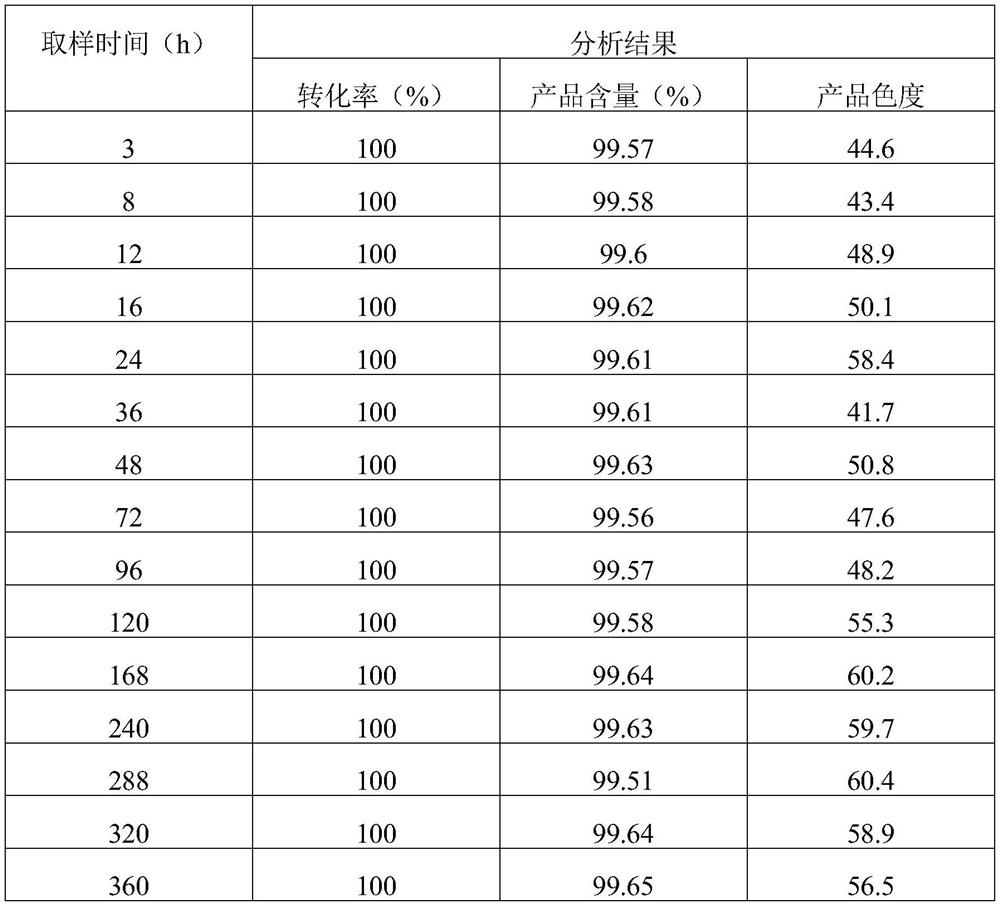

Embodiment 2

[0039] Preparation of sodium disulfide reducing solution:

[0040] first to 5m 3 Add 3.4m 3 of water, start stirring, and 1300kg of sodium sulfide (mass content is 60%) is added in batches in the first raw material preparation still, then in the first raw material preparation still, add the solid sulfur of 330kg, in order to prevent the reaction system from generating The highly toxic hydrogen sulfide gas overflows and hurts employees. The system uses the induced draft fan to maintain a slight negative pressure in the first raw material preparation kettle, and at the same time the gas discharged by the induced draft fan is absorbed by spraying sodium hydroxide solution. The tail gas produced by the reaction is absorbed by the lye. The first raw material preparation kettle is heated slowly to 95°C. After the sodium sulfide and sulfur are completely dissolved, continue to keep warm for 1.5 hours. Then, after the reaction system cools down to 75°C, it is filtered through the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com