Chain plate conveying device

A conveying device and chain plate technology, which is applied in the transmission field, can solve problems such as slippage, high gear cutting precision, and high installation precision requirements, and achieve the effects of no need for lubrication and maintenance, long transmission distance, and low maintenance cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

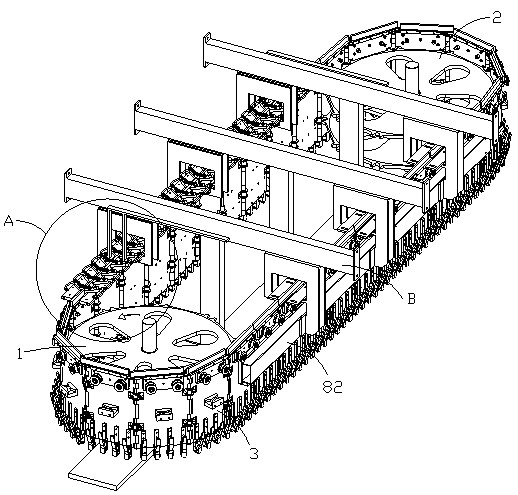

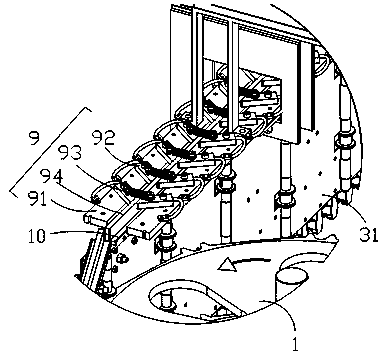

[0060] see Figure 1-7 As shown, Embodiment 1 of the present invention discloses a chain plate conveying device. The chain plate conveying device adopts a vertical conveying mechanism as a whole, which includes a driving sprocket 1, a driven sprocket 2 and a conveyor belt 3. The conveyor belt 3 includes a plurality of The chain plates 31 connected in series by means of hinges, the outer edges of the driving sprocket 1 and the driven sprocket 2 are respectively evenly distributed with ten pairs of locking teeth 4, and the chain plate 31 is provided with a locking hole 311. When the chain plate 31 passes through the driving chain When the pulley 1 or the driven sprocket 2 is used, the locking teeth 4 are inserted into the clamping holes 311 so that the chain plate 31 rotates under the rotation of the driving sprocket 1 or the driven sprocket 2, the conveyor belt 3 is perpendicular to the horizontal plane, and the chain plate 31 The whole is perpendicular to the horizontal plane,...

Embodiment 2

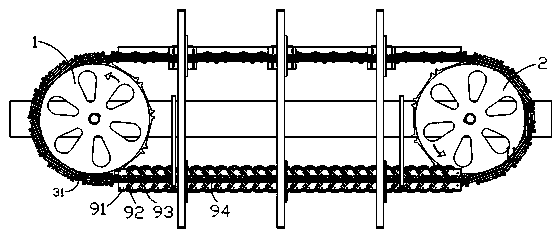

[0072] see Figure 8-12 As shown, Embodiment 2 of the present invention discloses a chain plate conveying device, the chain plate conveying device adopts a horizontal conveying mechanism as a whole, which includes a driving sprocket 1', a driven sprocket 2' and a conveyor belt 3', and the conveyor belt 3 'includes a plurality of chain plates 31' that are connected in series by hinges, and the chain plates 31' are hinged on both sides in the width direction, and ten pairs are evenly distributed on the outer edges of the driving sprocket 1' and the driven sprocket 2' The locking tooth 4', the locking hole 311' is provided on the chain plate 31', when the chain plate 31' passes the driving sprocket 1' or the driven sprocket 2', the locking tooth 4' is inserted into the locking hole 311' so that The chain plate 31' rotates under the rotation of the driving sprocket 1' or the driven sprocket 2', the conveyor belt 3' moves horizontally, the chain plate 31' is arranged parallel to th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com