Production technology of semicircle groove internal threaded steel pipe

A semi-circular groove and production process technology, which is applied to threaded products, other household appliances, household appliances, etc., can solve the problems of short service life, loss of use value of steel pipes, time-consuming and labor-intensive processing of steel pipes, etc., and achieve long service life , simple processing, and the effect of improving heat dissipation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

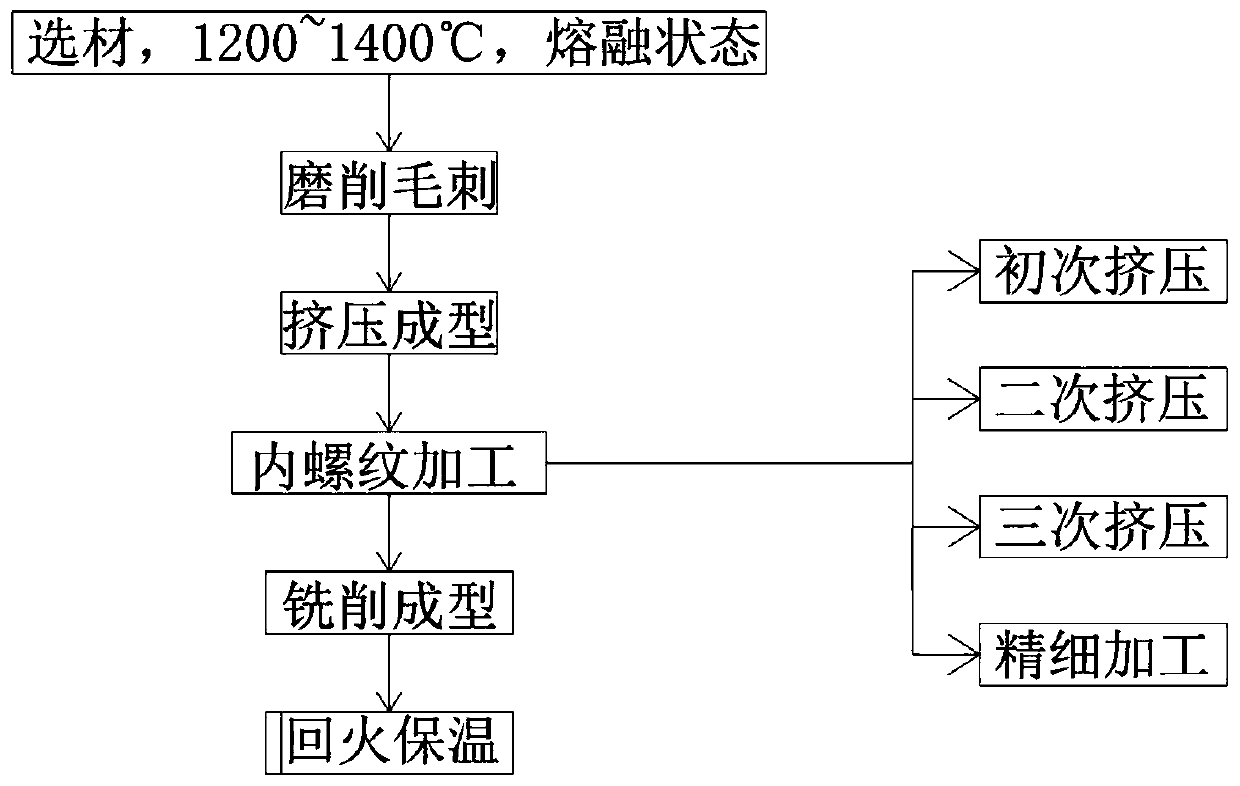

[0037] The production process of semicircular groove internally threaded steel pipes, the technical proposal of which includes the following steps:

[0038] Step 1: Material selection, heating and melting the selected steel into a molten state, the heating temperature of the steel is 1200°C until the steel is melted into a molten state, and injecting the molten liquid into the mold to prepare a steel ingot;

[0039] Step 2, grinding, milling the steel ingot prepared from the liquid on a grinding machine, and grinding the burrs around the steel ingot;

[0040] Step 3: Extrusion molding, heating the steel ingot processed by the milling machine, then extruding the steel ingot through a large extruder, and processing the steel ingot into a steel pipe, the heating temperature is 600°C;

[0041] Step 4: internal thread processing, processing internal threads on the inner side of the steel pipe;

[0042] Step 5: Milling, milling half of the internal thread on the inner side of the s...

Embodiment 2

[0050] The production process of semicircular groove internally threaded steel pipes, the technical proposal of which includes the following steps:

[0051] Step 1: Material selection, heating and melting the selected steel into a molten state, the heating temperature of the steel is 1400°C until the steel is melted into a molten state, and injecting the molten liquid into the mold to prepare a steel ingot;

[0052] Step 2, grinding, milling the steel ingot prepared from the liquid on a grinding machine, and grinding the burrs around the steel ingot;

[0053] Step 3: Extrusion molding, heating the steel ingot processed by the milling machine, then extruding the steel ingot through a large extruder, and processing the steel ingot into a steel pipe, the heating temperature is 800°C;

[0054] Step 4: internal thread processing, processing internal threads on the inner side of the steel pipe;

[0055] Step 5: Milling, milling half of the internal thread on the inner side of the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com