Calender for producing fresh wet noodles

A calender and noodle technology, which is applied in dough forming machinery or equipment, dough sheeter/roller/rolling pin, application, etc., can solve the problem of difficulty in ensuring uniform dough thickness, single type of dough thickness and easy to run. To solve the problem of partial and other problems, to achieve the effect of improving production efficiency and production quality, real-time automatic adjustment of pressure roller spacing, and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

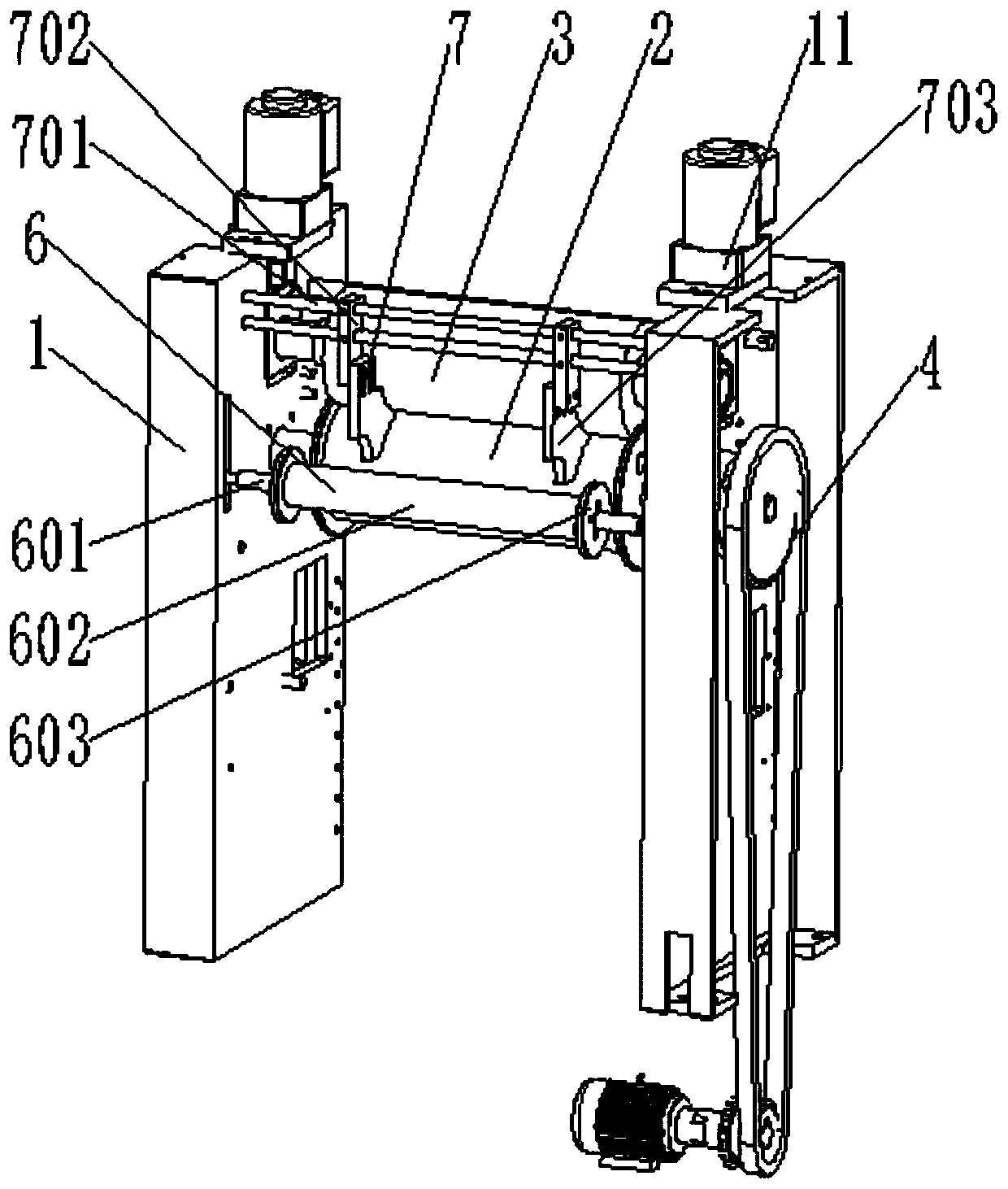

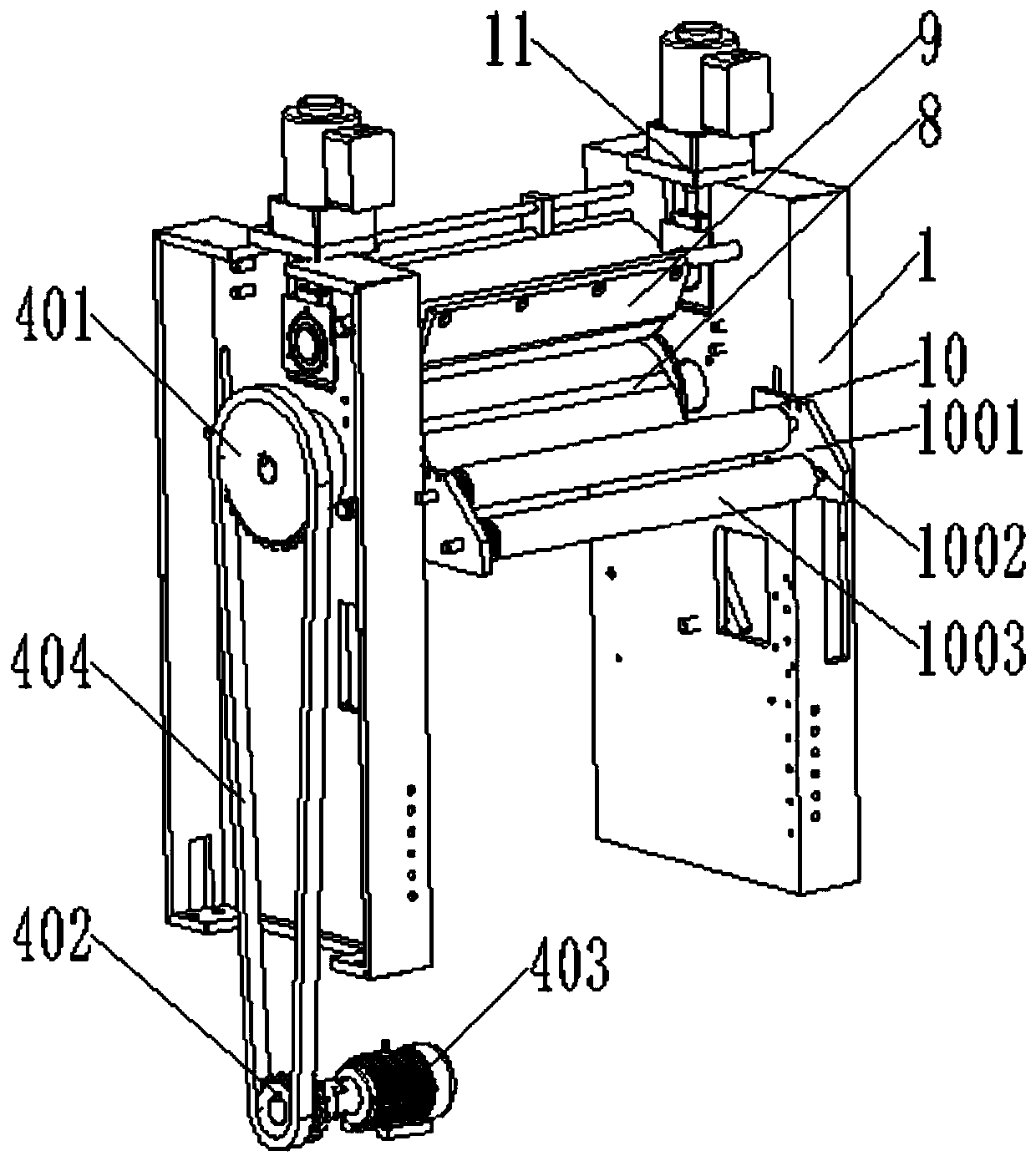

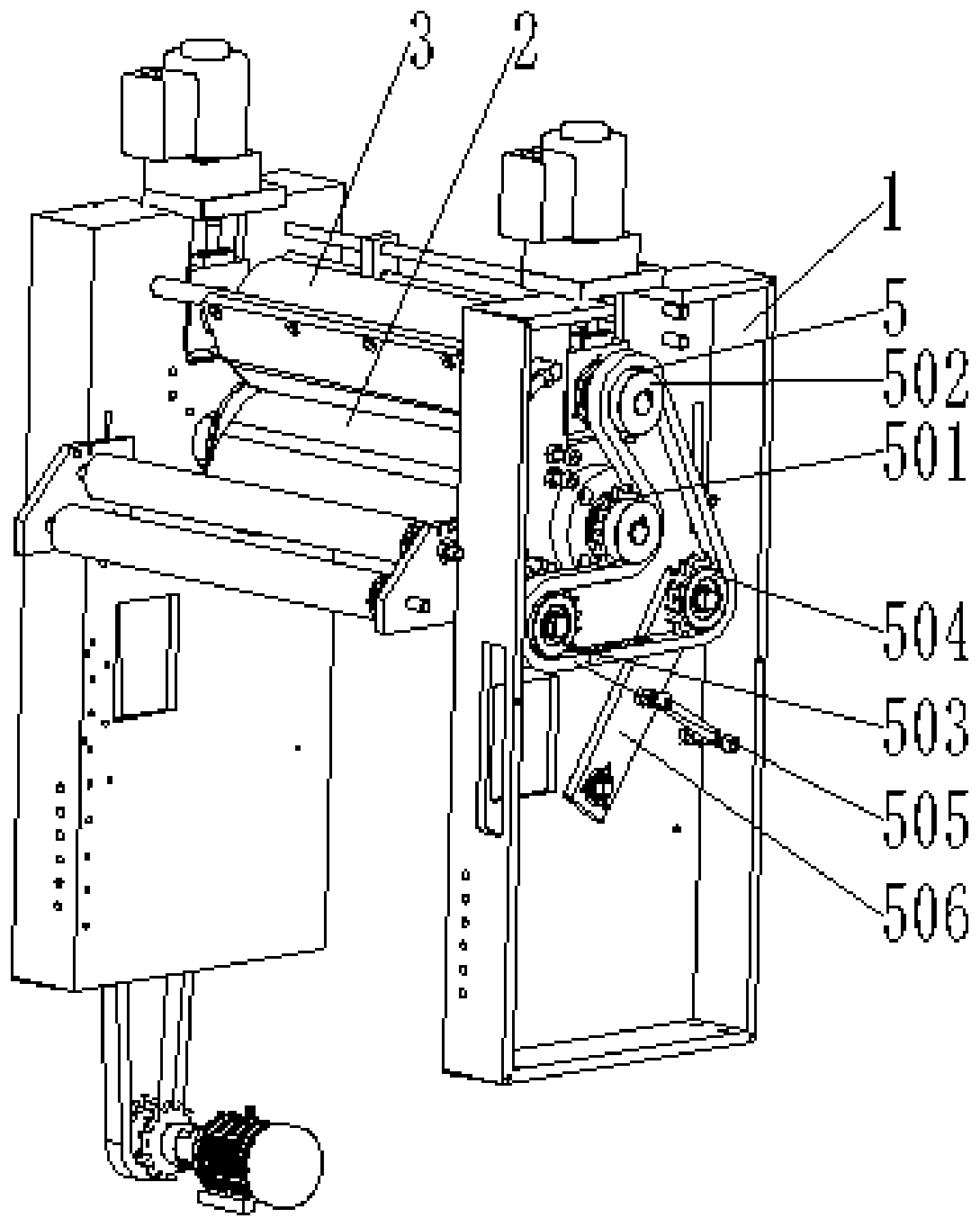

[0047] Such as Figure 1 to Figure 4 As shown, the present invention provides a kind of calender for making fresh and wet noodles, and this calender comprises:

[0048] The frame 1 arranged on both sides of the calender, the middle of the frame 1 is provided with a lower roll 2 and an upper roll 3, one end of the lower roll 2 is connected with a driving mechanism 4, the other end of the lower roll 2 is connected with one end of the upper roll 3 A transmission mechanism 5 is arranged between them, a dough input support assembly 6 is provided on the front side of the lower roller 2, a limit plate assembly 7 is installed on the front side of the upper roller 3, and a rear side of the lower roller 2 and the upper roller 3 is respectively arranged There is a lower roller scraping knife assembly 8 and an upper roller scraping knife assembly 9, a dough output support assembly 10 is arranged behind the lower roller 2 in the middle of the frame 1, and an upper roller distance adjustmen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com