Process method for quickly fattening Simmental bulls with grain fodder

A process method, Simmental's technology, applied in the field of livestock breeding, can solve the problems of inconsistent nutritional content of corn silage in the whole plant, cumbersome feeding methods, and many feed raw materials, etc., to ensure normal rumination function, good palatability of cattle, and promotion of rumination. effect of function

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

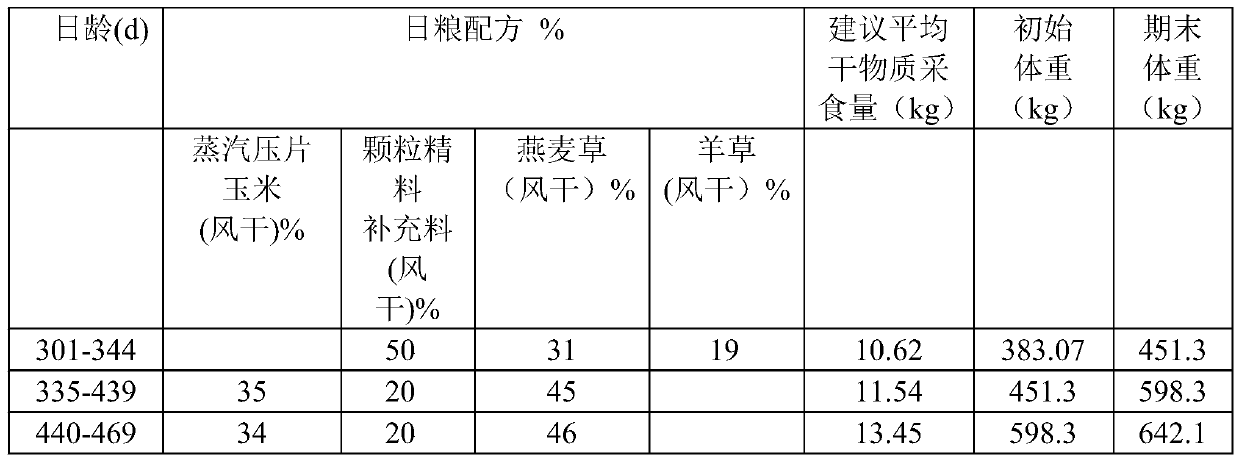

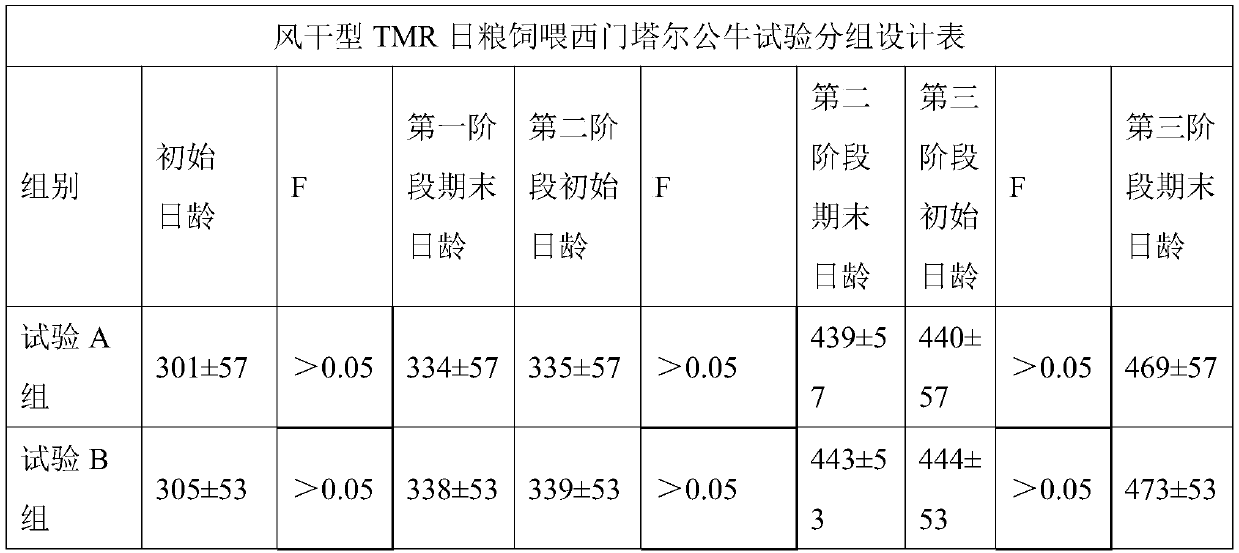

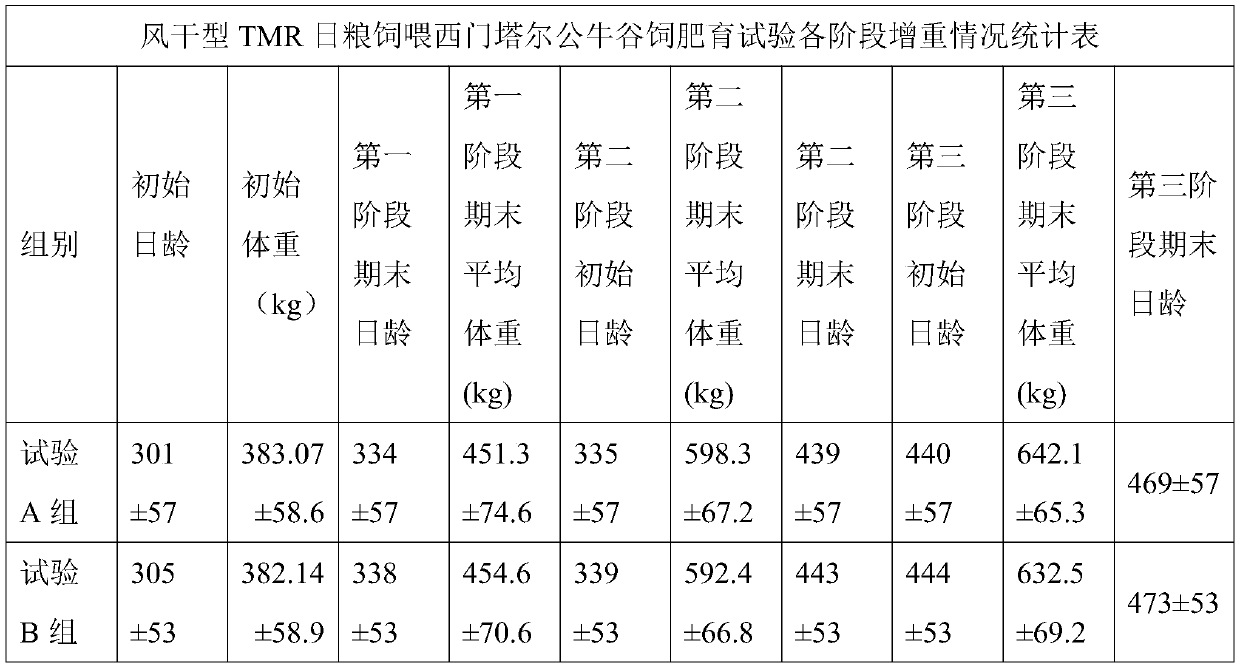

[0020] Specific embodiment 1: This embodiment records a process method for rapid fattening of Simmental bulls by grain feeding, and the target breeds are: F hybrid of German Simmental bulls and Australian Simmental cows 1 For the generation of bulls, the method is specifically as follows: start fattening of Simmental bulls at the age of 301 days, raise them in a semi-open barn, and remove manure once a day in the morning, and the ambient temperature is from May to October, the lowest temperature 5 Change from ℃ to the highest temperature of 30℃, feed once a day at 13:00 every day, mix with a fully mixed ration TMR feeding cart to make an air-dried TMR ration with moisture below 14%, and the trough is not empty for 24 hours Groove until the Simmental Bull is 469 days old to be released;

[0021] From 301 days to 334 days of age, the ration formula, calculated by air-drying quantity, is composed of 50% granular concentrate supplements, 31% oat grass, and 19% of leymus chinensis; the...

specific Embodiment approach 2

[0024] Specific embodiment two: a process method for fast fattening Simmental bull grain feed described in specific embodiment 1, the specific composition and content of the granular concentrate supplement are as follows:

[0025] Granular concentrate supplements from 301 days to 469 days of age are based on the mass parts from 15 to 50 parts of corn, 15 parts of soybean meal, 15 parts to 35 parts of DDGS, 10 parts to 30.75 parts of sprayed corn germ meal, sprayed corn 11 parts of husk, 15 parts of palm meal, 3 parts~3.75 parts of sugar cane molasses, 1.99 parts~5 parts of 40 mesh stone powder, 0.5~2.5 parts of beef premix additives, 0.5~2.5 parts of salt, 1 part of sodium bicarbonate~ 5 parts, gelatinized sustained-release urea of 200 is composed of 1 part. The DDGS is corn distillers grains with a moisture content of less than 14% and its solubles.

specific Embodiment approach 3

[0026] Specific embodiment three: The process method for fast fattening Simmental bull grain feed described in specific embodiment two, the bulk density rz of the corn is higher than 710; the crude protein content of the sprayed corn husk> 18%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com