Compression cracking prevention necking machine for shell head of clamping plate type male joint

A splint-type, shrinking technology, which is applied in the manufacturing of contact boxes/bases, etc., can solve the problems of cracking of the splint-type male head, collapse of the inner layer, and failure to achieve the shrinking effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0028] as attached figure 1 to attach Figure 7 Shown:

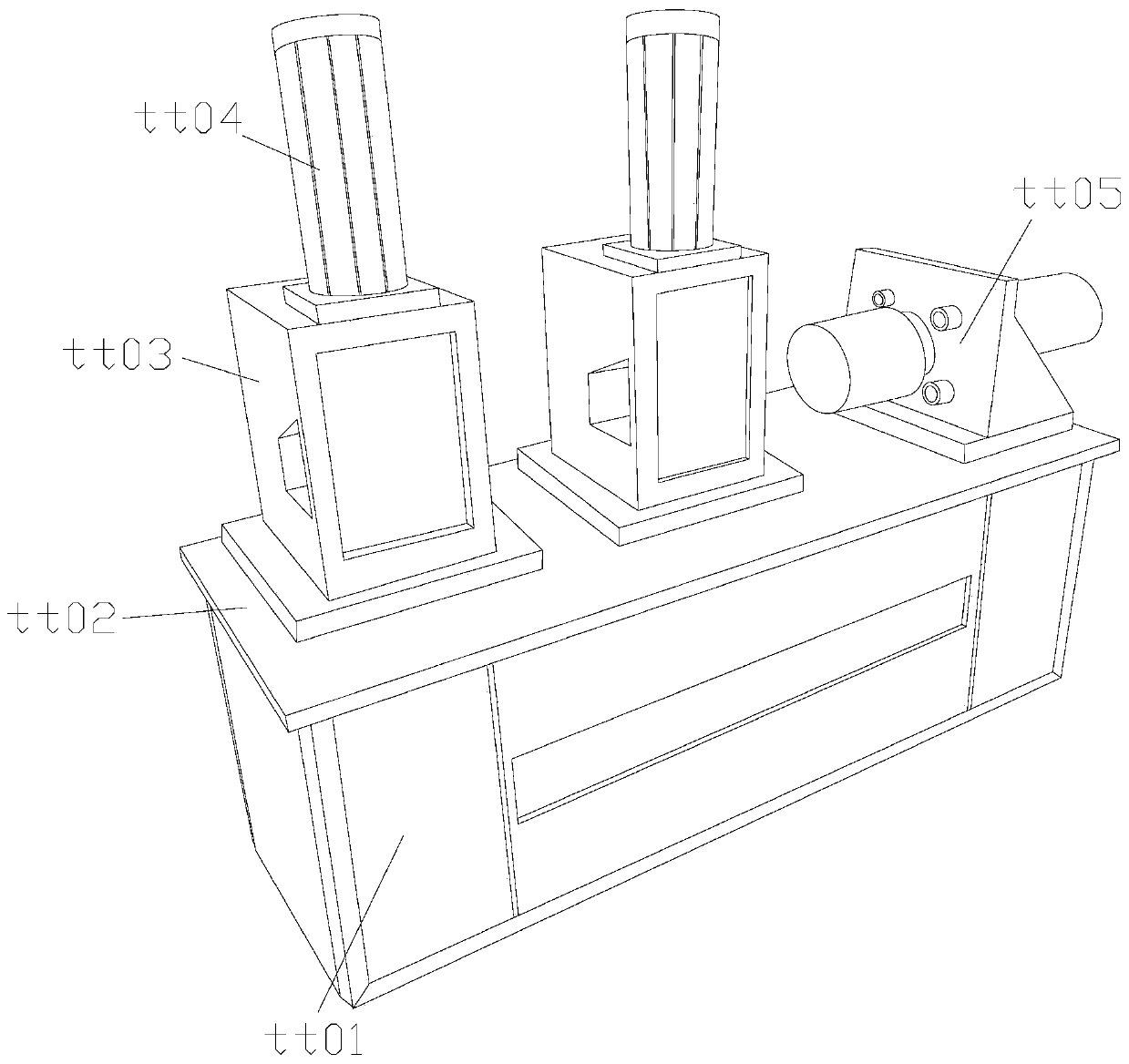

[0029] The invention provides a splint-type male shell head anti-compression cracking necking machine, the structure of which includes a bottom control box tt01, a top support plate tt02, a necking box tt03, a necking pressure tube tt04, and a side push frame tt05.

[0030] The bottom end of the top supporting plate tt02 is welded to the upper surface of the bottom control box tt01, and the end of the top supporting plate tt02 away from the bottom control box tt01 is connected to the necking box tt03, and the upper surface of the necking box tt03 has a necking hole The pressure tube tt04, the side push frame tt05 and the necking box tt03 are installed on the same level.

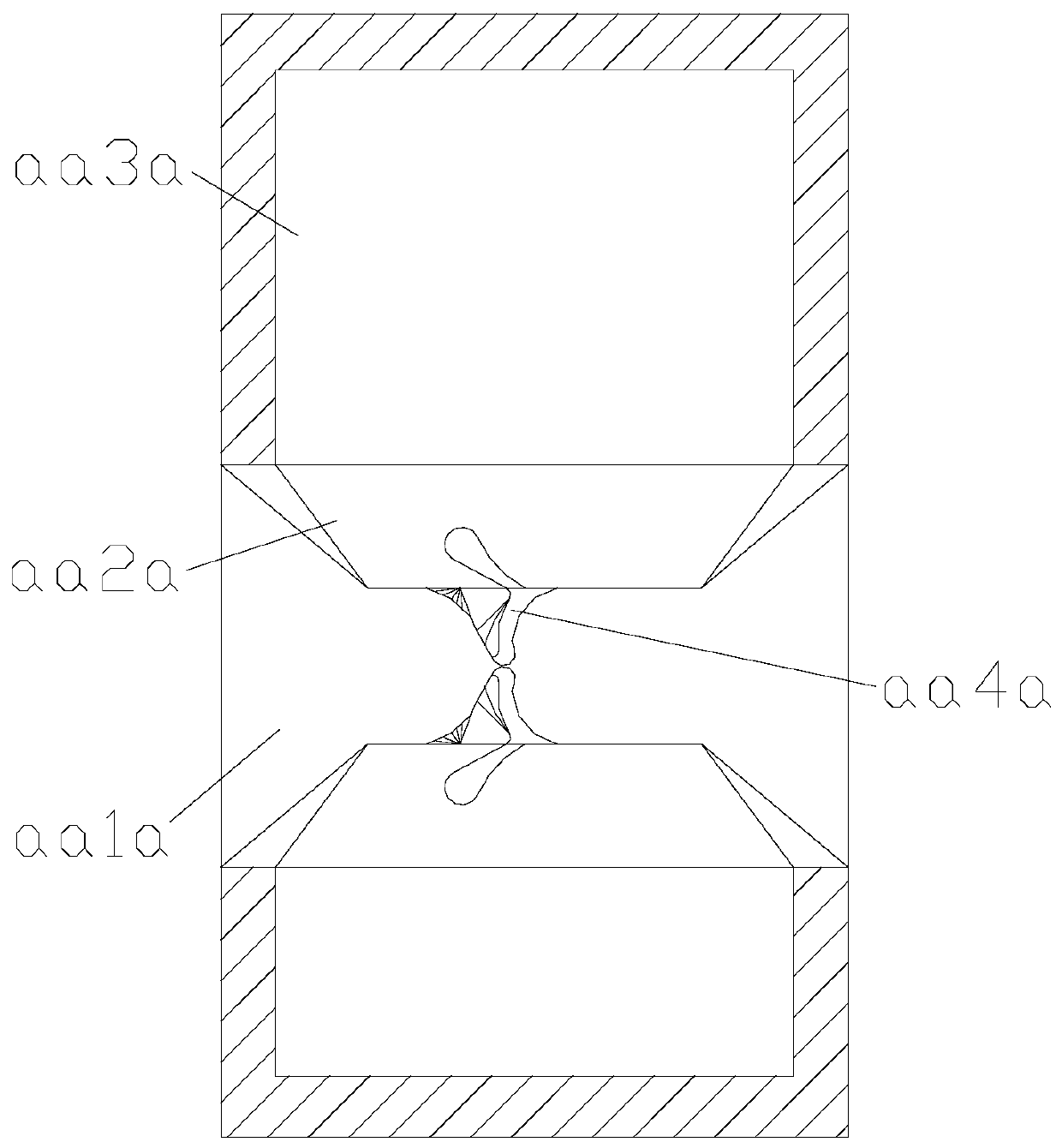

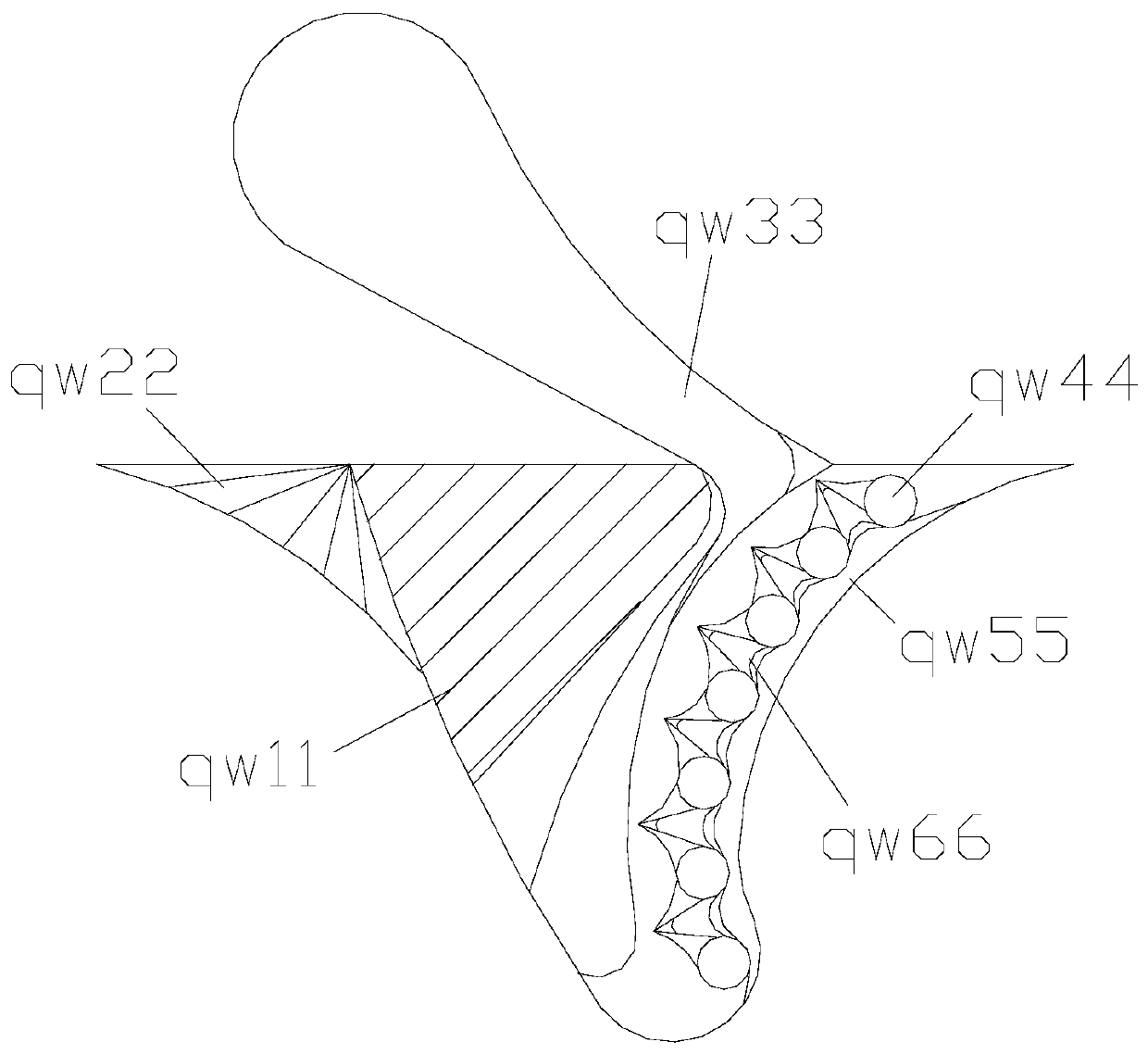

[0031] The necking box tt03 includes necking channel aa1a, necking top plate aa2a, internal control box aa3a, plug angle aa4a, the necking channel aa1a is installed between the necking top plate aa2a, the plug angle aa4a and the necking The top plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com