Combined steam injection device

A combined, steam technology, applied in the field of ejectors, can solve the problems of drastic changes in the ejection performance of the ejector and the inability to achieve the best ejection performance of the ejector, and achieve the effect of avoiding the impact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

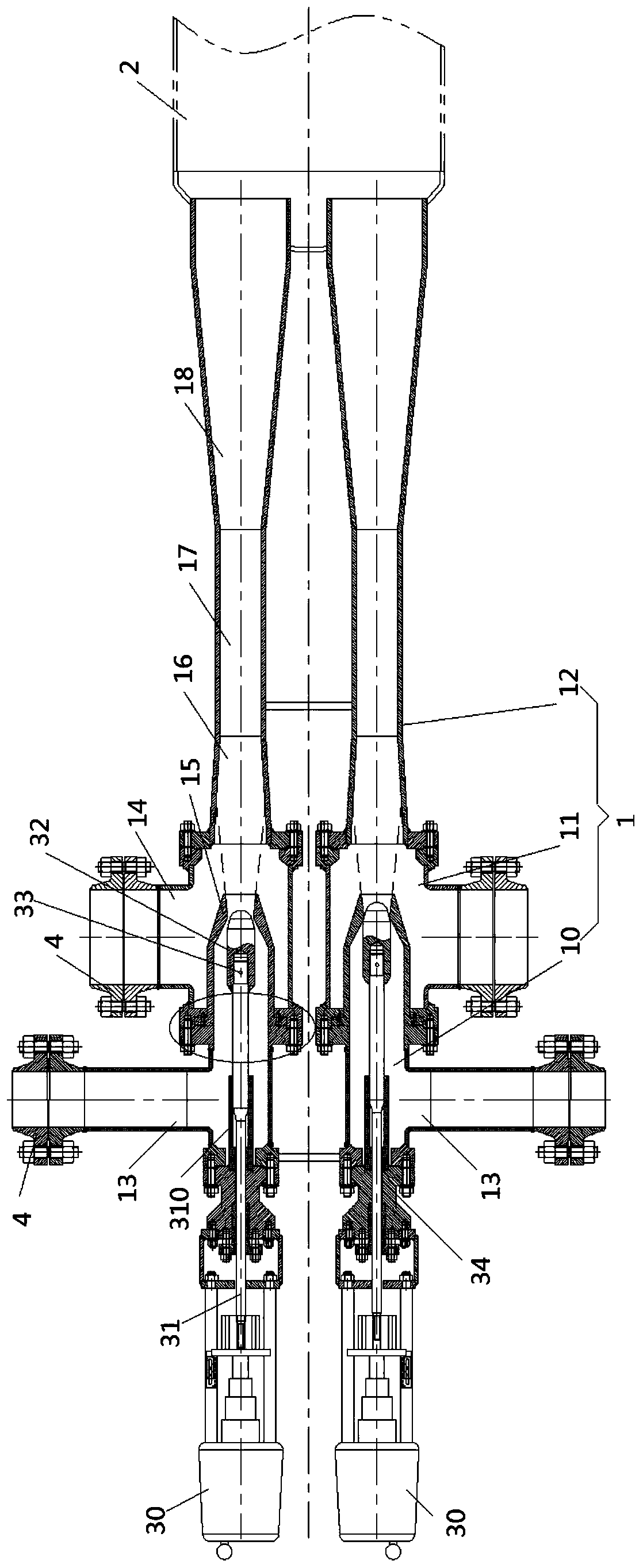

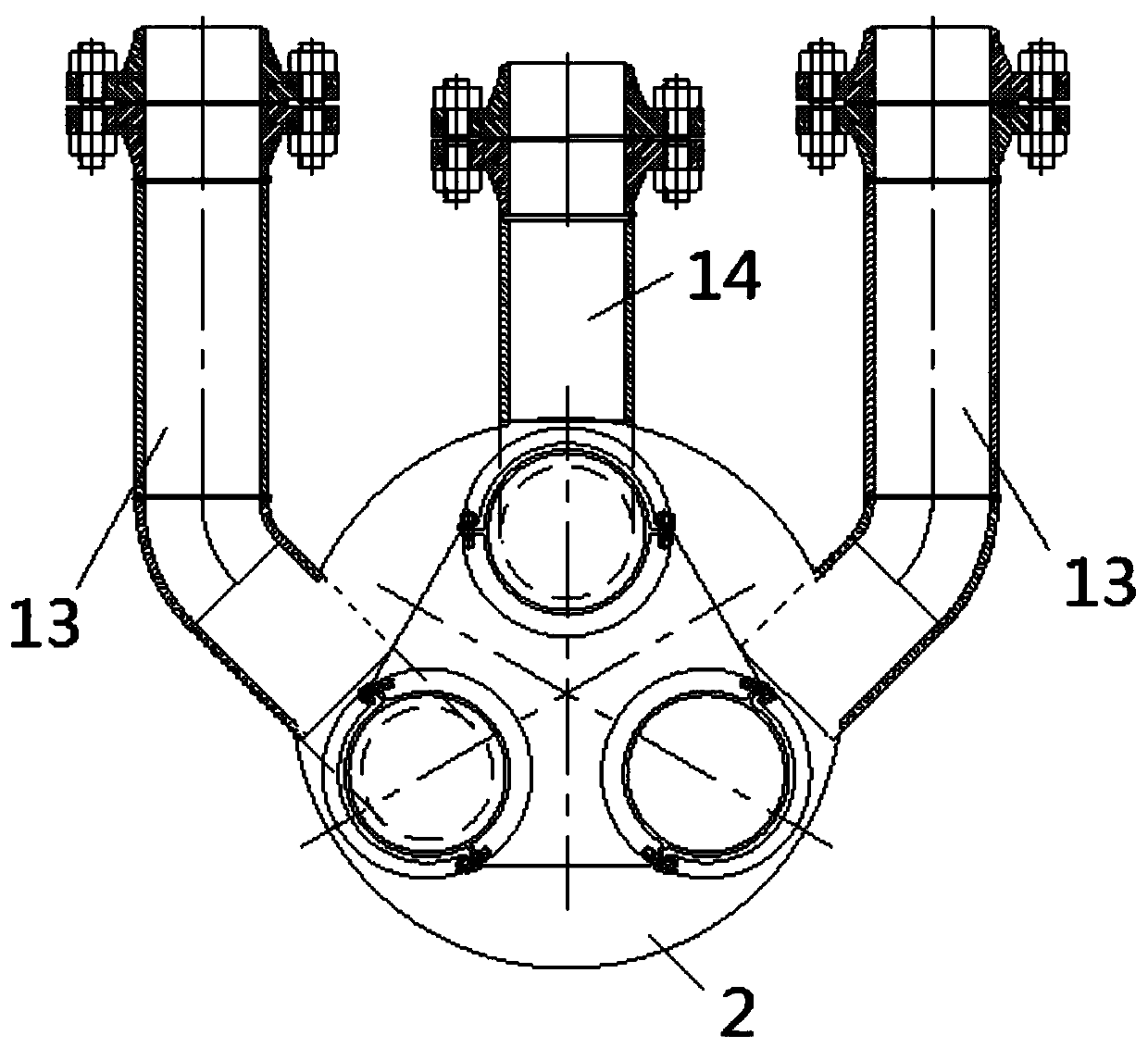

[0022] The invention provides a combined steam injection device, such as figure 1 and image 3 As shown, it includes several ejectors 1 and connecting parts 2 that are independently arranged, wherein, several of the ejectors 1 are sealed and connected with the connecting part 2, and several of the ejectors 1 are provided with There is a throttling mechanism for individually controlling the flow rate of the working fluid in each of the ejectors 1; the ejectors 1 communicate with the external steam pipeline through the connecting part 2. Preferably, there are three ejectors 1 .

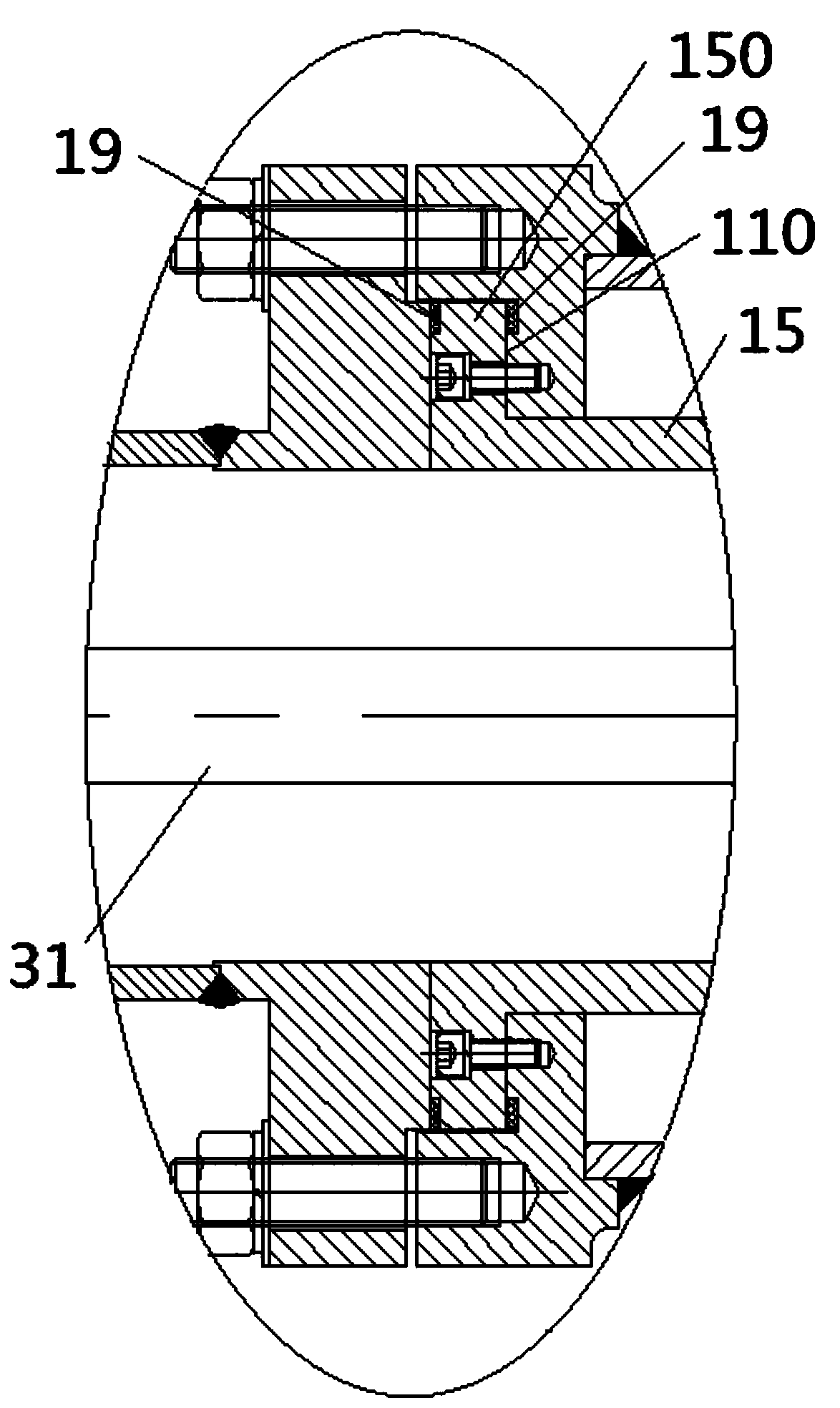

[0023] The ejector 1 includes a high-pressure steam chamber 10, a low-pressure steam chamber 11, and a mixed steam chamber 12 that communicate with each other, wherein the side walls of the high-pressure steam chamber 10 and the low-pressure steam chamber 11 are respectively provided with working fluid inlets 13 and ejection fluid inlet 14; one end of the high-pressure steam chamber 10 communicates wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com