Quality inspection management and tracking method and system, storage medium and computer

A tracking system and quality inspection technology, which is applied in computing, manufacturing computing systems, data processing applications, etc., can solve the problems of being unable to meet the comprehensive management requirements of the quality inspection process of discrete assembly enterprises, ignoring the ultimate purpose, etc., to improve product fault tolerance rate, reduce the effect of substandard products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

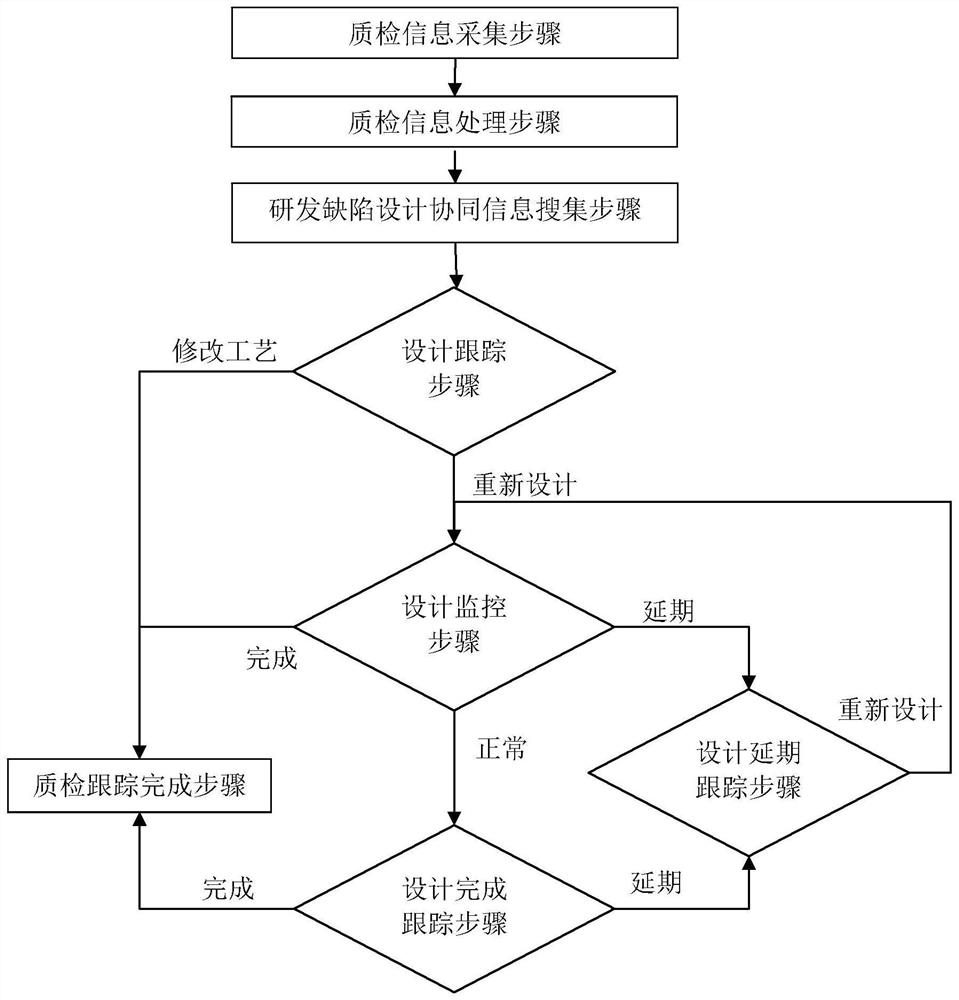

[0048] Embodiment 1. A quality inspection management and tracking method described in this embodiment, the quality inspection management and tracking method includes the following steps:

[0049] Quality inspection information collection step: collect quality inspection data and store the data; quality inspection data includes: quality inspection object name, quality inspection process data, process information and quality inspection results, and the quality inspection results include: qualified, overhaul, rework , R & D defects.

[0050] The process information includes: the processing time of the quality inspection object, the processing node, the design node, and the next process node.

[0051] Quality inspection information processing step: the step of processing the corresponding quality inspection data according to the quality inspection result in the quality inspection data. When the quality inspection result is inspection, send the corresponding quality inspection data...

Embodiment 2

[0070] Embodiment 2. This embodiment is a further limitation of the quality inspection management and tracking method described in Embodiment 1. In the design monitoring step, the specified time is specifically 1-3 working days in advance, or One-third of the redesign cycle. By sending reminder information to the corresponding design nodes in advance, we can keep abreast of the progress and effectively avoid the extension of the related production cycle caused by overdue.

[0071] In this embodiment, a preferred way of specifying the time is stipulated, wherein: the fixed time can be selected within 1-3 working days. It can also be determined according to the redesign cycle, for example: the redesign cycle is 15 days, you can choose to make a design monitoring reminder 4 days before the end, the purpose is to understand the improvement progress of the designer, so that the entire production workshop can be adjusted in advance according to the progress work.

Embodiment 3

[0072] Embodiment 3. This embodiment is a further limitation of the quality inspection management and tracking method described in Embodiment 1. The quality inspection process data includes written records, photos of unqualified parts of the quality inspection, and images of the quality inspection process. Any one or more.

[0073] In the existing quality inspection report, generally only the quality inspection data and results are recorded. These contents are not conducive to the designer’s understanding of the specific process of the quality inspection and the details of the direct results. When the designer needs to make design improvements, it is often necessary for the designer to Regional quality inspection personnel understand the quality inspection process at that time and some intermediate results in the quality inspection process. In addition to the conventional text records, the quality inspection process data described in this embodiment also adds photos of the unq...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com