Production method of hot-galvanized low-alloy high strength steel having no yield point elongation and used for automobile sheets

A production method and no-yield technology, applied in the field of metallurgy, can solve the problems of low strength level, high alloy content, low yield strength, etc., achieve strong rolling capacity, large smooth rolling force control, and eliminate yield platform Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

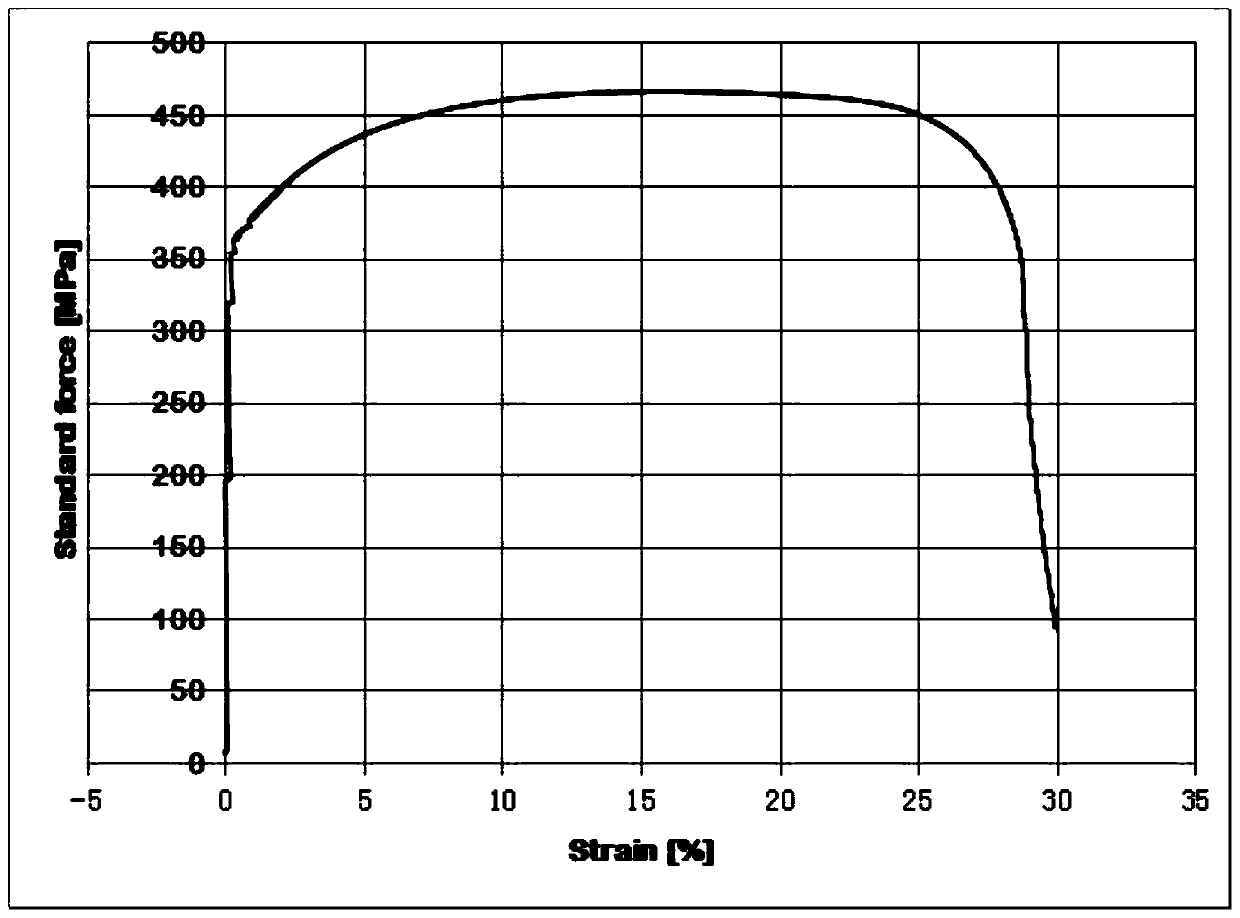

Image

Examples

Embodiment Construction

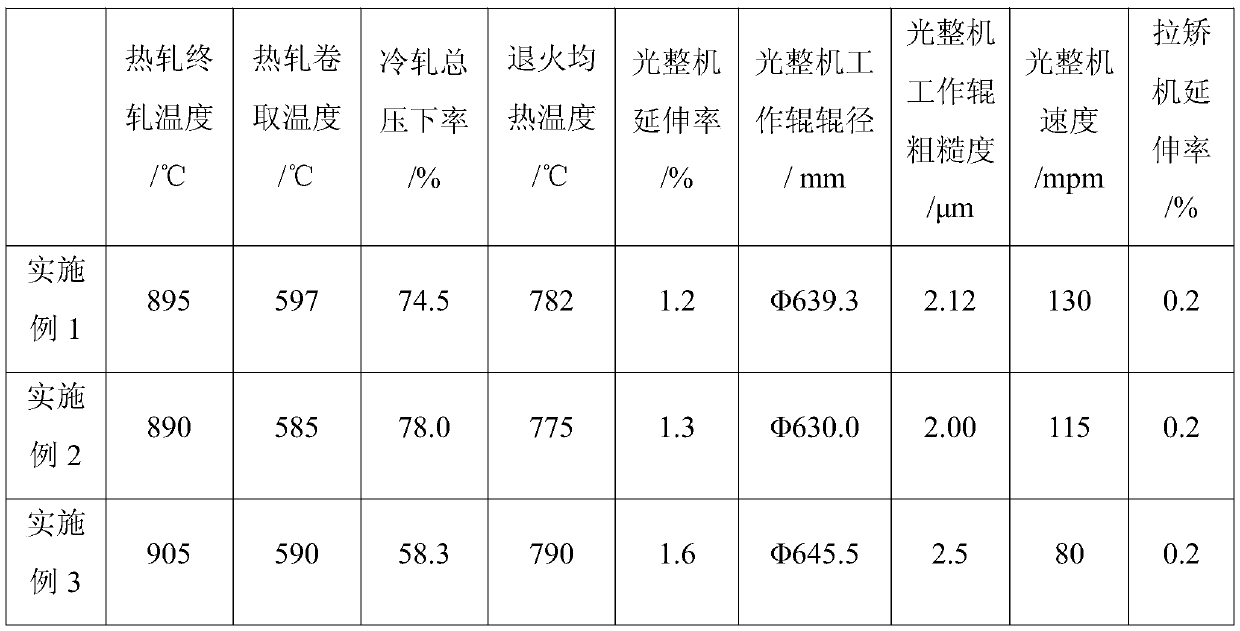

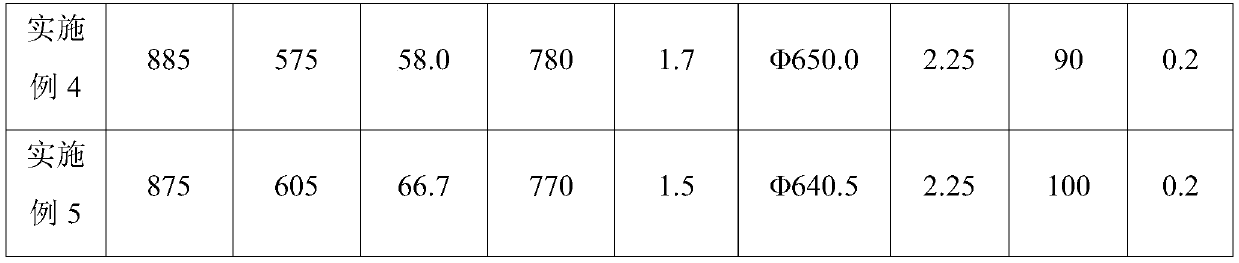

[0023] The following are specific examples of the present invention, further describing the technical solutions of the present invention, but the protection scope of the present invention is not limited to these examples. All changes or equivalent substitutions that do not depart from the concept of the present invention are included in the protection scope of the present invention.

[0024] Hot-dip galvanized low-alloy high-strength steel with no yield platform for automobile plates, the chemical composition and mass percentage of the steel are: C: 0.060-0.090%, Si≤0.05%, Mn: 0.65-0.75%, P: 0.015- 0.025%, S≤0.010%, Als: 0.025~0.06%, Nb: 0.025~0.035%, N≤0.0040%, the rest is Fe and unavoidable impurities.

[0025] The production method of hot-dip galvanized low-alloy high-strength steel with no yield platform for automobile plates includes smelting, continuous casting, hot rolling, acid continuous rolling, and hot-dip galvanizing processes. In the hot rolling process, the exit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com