Method for producing L-leucine by fermentation

A leucine and fermenter technology, applied in the field of fermentation and production of L-leucine, can solve problems such as high cost, unsuitable for large-scale production, and cumbersome procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A method for producing L-leucine by fermentation, comprising the steps of:

[0029] Test strain: Brevibacterium flavum ( Brevibacterium flavum ) TK0303 (Met - +Ile L +2-TA r +α-AB r +β-HL r +Rif r +SG r ).

[0030] The Brevibacterium flavum seed solution was obtained by conventional culture methods, and the Brevibacterium flavum seed solution was inserted into a 500L fermenter equipped with a 300L fermenter medium at an inoculation amount of 10%, and the inoculation concentration was OD 600 1.5; the stirring speed is 400r / min; the dissolved oxygen is controlled at 25% by stirring and ventilation; the pH is controlled at 7.0 by automatic flow of ammonia water; the cultivation temperature is 33°C; Feed into the tank, maintain the sugar concentration in the fermentation tank at 1g / L, stop feeding 6 hours before the end of fermentation; the fermentation period is 44h.

[0031] Components of the fermenter culture medium: glucose 50g / L, (NH 4 ) 2 SO 4 10g / L, cor...

Embodiment 2

[0037] A method for producing L-leucine by fermentation, comprising the steps of:

[0038] Test strain: Brevibacterium flavum ( Brevibacterium flavum ) TK0303 (Met - +Ile L +2-TA r +α-AB r +β-HL r +Rif r +SG r ).

[0039] The Brevibacterium flavum seed solution was obtained by conventional culture methods, and the Brevibacterium flavum seed solution was inserted into a 500L fermenter equipped with a 300L fermenter medium at an inoculation amount of 8%, and the inoculation concentration was OD 600 1.8; the stirring speed is 350r / min; the dissolved oxygen is controlled at 25% by stirring and ventilation; the pH is controlled at 6.8 by automatic flow of ammonia water; the cultivation temperature is 33°C; Feed into the tank, maintain the sugar concentration in the fermentation tank at 1g / L, stop feeding 6 hours before the end of fermentation; the fermentation period is 44h.

[0040] Components of the fermenter culture medium: glucose 50g / L, (NH 4 )2 SO 4 10g / L, corn s...

Embodiment 3

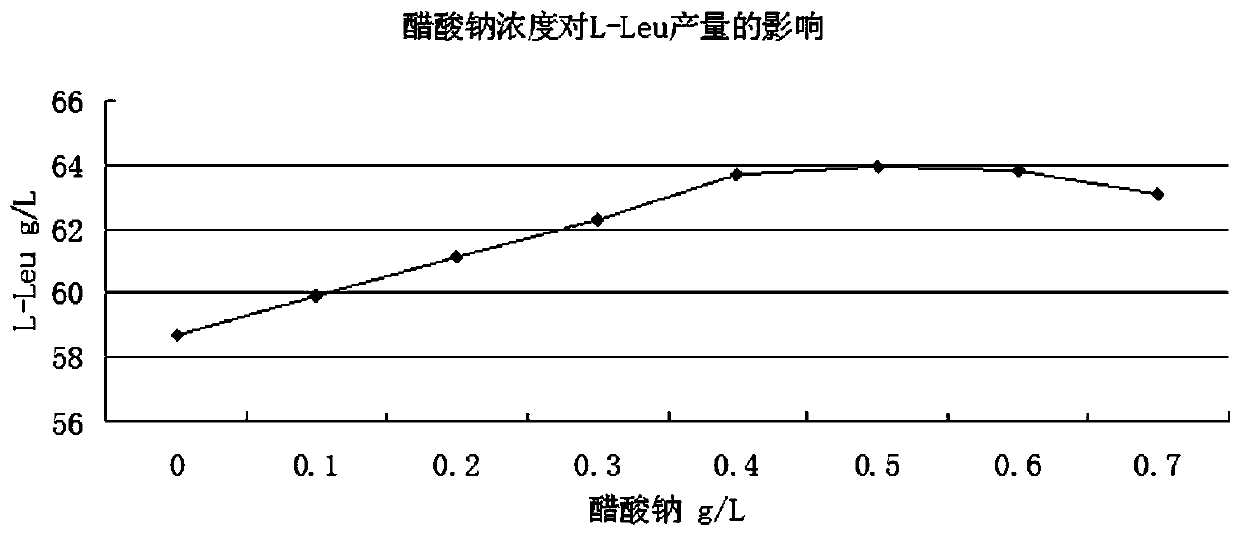

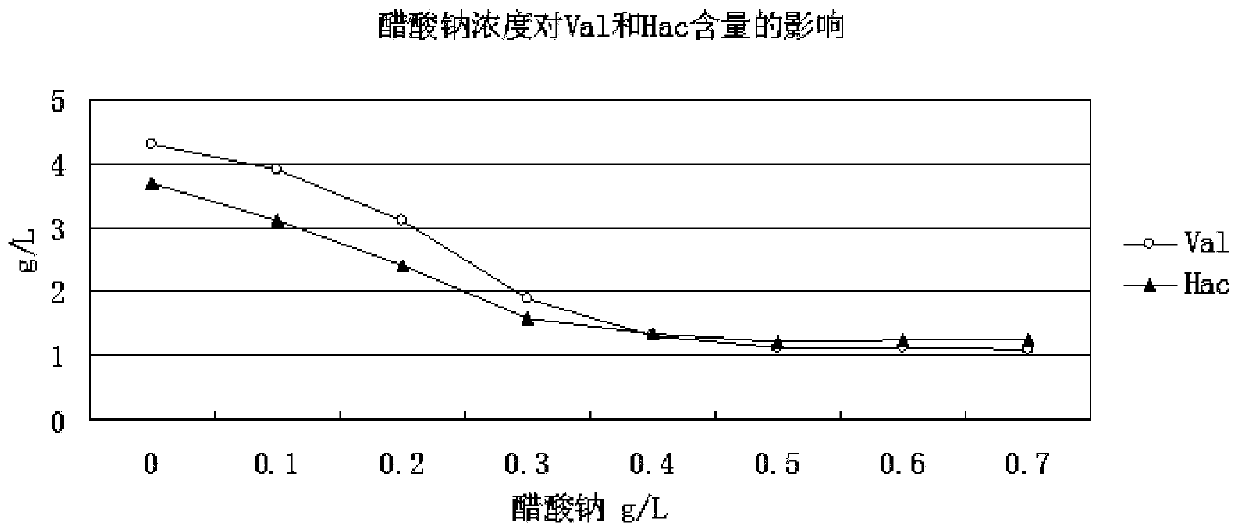

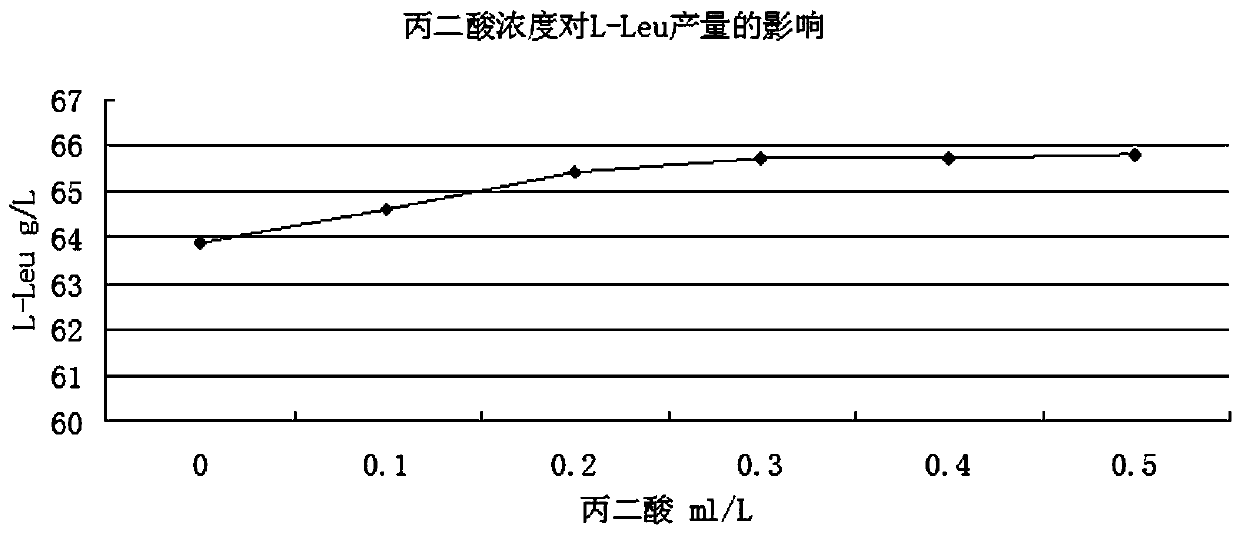

[0050] 1. On the basis of the conventional fermentation of Comparative Example 1, the effect of the added concentration of sodium acetate on the fermented liquid was checked. L- Leu and the influence of the main by-product content. Set the concentration gradient of sodium acetate in the fermentation broth, respectively 0, 0.1, 0.2, 0.3, 0.4, 0.5, 0.6, 0.7, the unit is g / L. like Figure 1-2 As shown, with the increase of sodium acetate concentration, the L- The content of Leu increases steadily, while the content of by-products Val and Hac gradually decreases. When the concentration of sodium acetate increases to 0.5g / L, the content of L-Leu reaches the maximum value. Continue to increase the content of sodium acetate, and the content of L-Leu does not increase At this time, the content of the by-products Val and Hac did not continue to decrease, indicating that at this time, the metabolic fluxes have reached equilibrium. During the fermentation process, by adding an appropr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com