A kind of fermentation method that improves fusothermal bacillus cellulase enzyme activity

The technology of a kind of fusothermal bacterium and fermentation method is applied in the fermentation field of improving the enzymatic activity of fusothermal bacterium cellulase, which can solve the problems of high cost, low enzyme activity, and limitation of wide application, and achieve high heat resistance and moisture resistance, Effect of improving cellulase activity and optimizing fermentation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

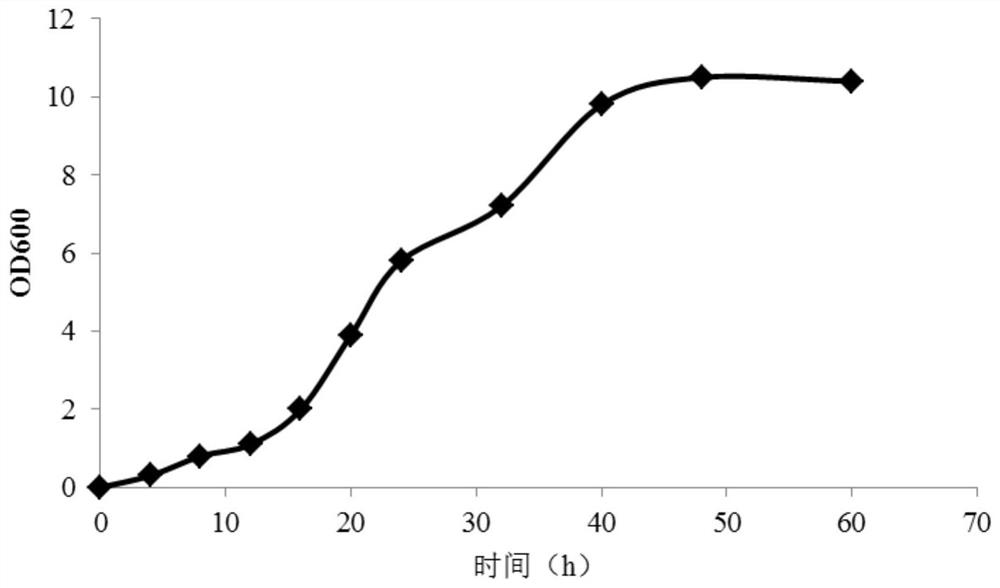

Image

Examples

Embodiment 1

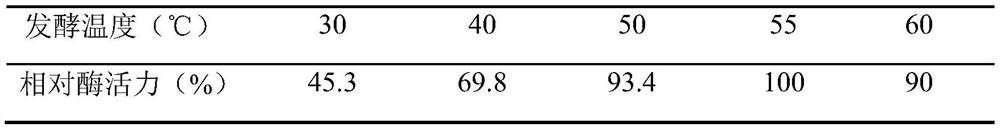

[0023] Preparation of cellulase under different fermentation temperatures in embodiment 1

[0024] Set different fermentation temperatures, respectively 30, 40, 50, 55, and 60° C., and ferment for 72 hours. Cellulase activity was measured after fermentation. The results are shown in Table 1. It was found that the relative enzyme activity of the bacteria could reach more than 90% under the condition of 50-60°C.

[0025] Table 1 Effect of different fermentation temperatures on enzyme activity

[0026]

Embodiment 2

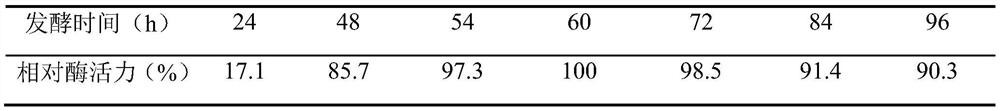

[0027] Preparation of cellulase under the different fermentation time of embodiment 2

[0028] Set different cultivation time, respectively 24h, 48h, 60h, 72h, 84h, 96h, culture at 60°C, and measure cellulase activity after fermentation. The results are shown in Table 2. With the increase of fermentation time, the enzyme activity showed an upward trend. The enzyme activity reached a peak at 60 hours of fermentation, and the enzyme activity began to decline at 96 hours. Therefore, the fermentation is stopped after 60 hours, which can greatly save the fermentation cost.

[0029] Table 2 Effects of different fermentation times on enzyme activity

[0030]

Embodiment 3

[0031] Preparation of cellulase under different initial pHs of embodiment 3

[0032] Control other conditions unchanged, set different initial pH of the medium, respectively 5.5, 6, 6.5, 7, 7.5, 8, ferment at 60°C for 72 hours, and measure cellulase activity after fermentation. The results are shown in Table 3. When the initial pH of the culture medium is 6.5-8, the relative enzyme activity can reach more than 90%.

[0033] Table 3 Effect of initial pH of different medium on enzyme activity

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com