High-value utilization method of lignin in black liquor

A lignin and high-value technology, which is applied in the field of high-value lignin utilization in black liquor, can solve the problems of low recycling rate and complex structure, and achieve the effect of less equipment, high purity and expanded application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] (1) Take 100ml of the above black liquor sample, filter it with filter paper to remove solid impurities, add 900ml of distilled water to dilute to obtain a dilution;

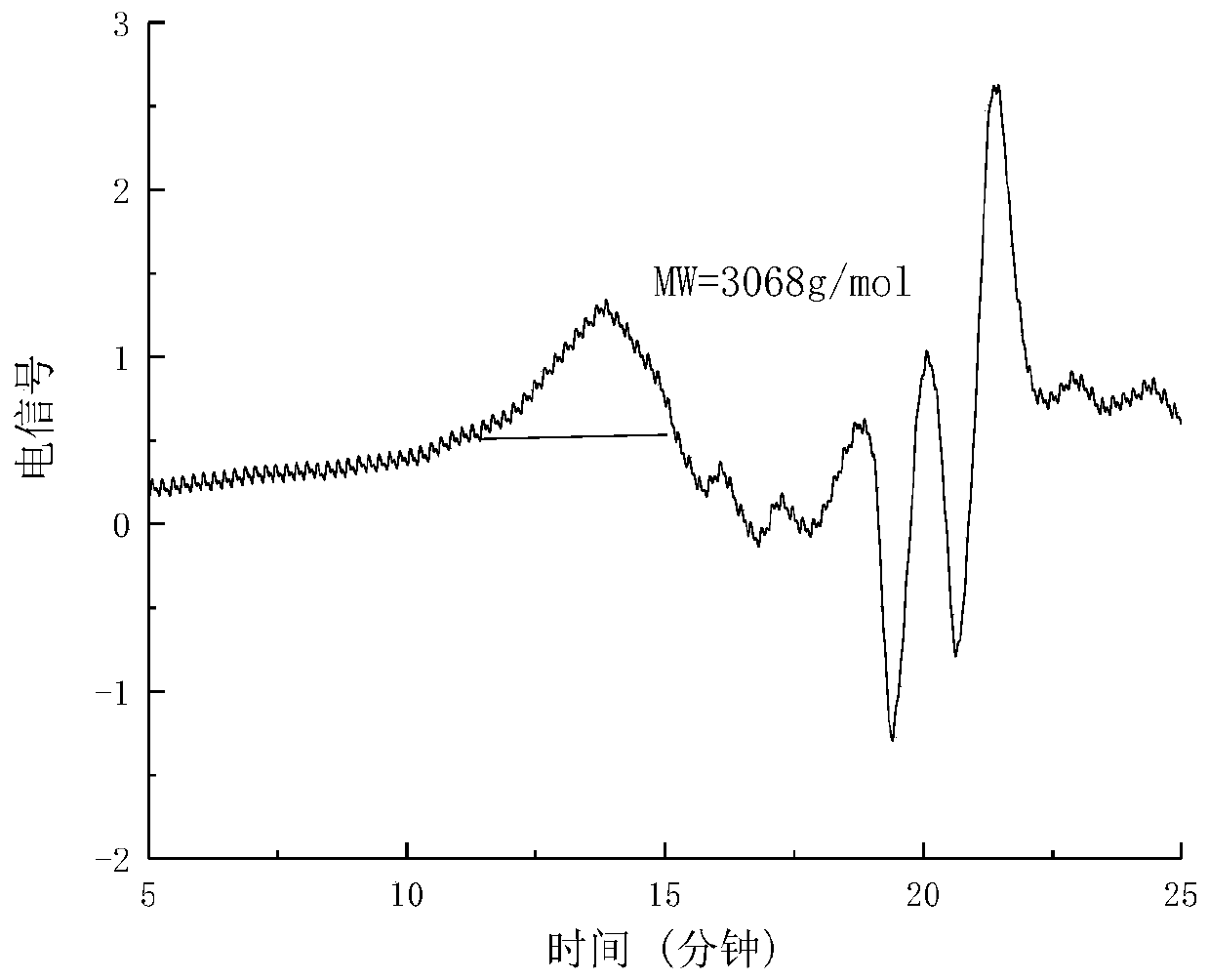

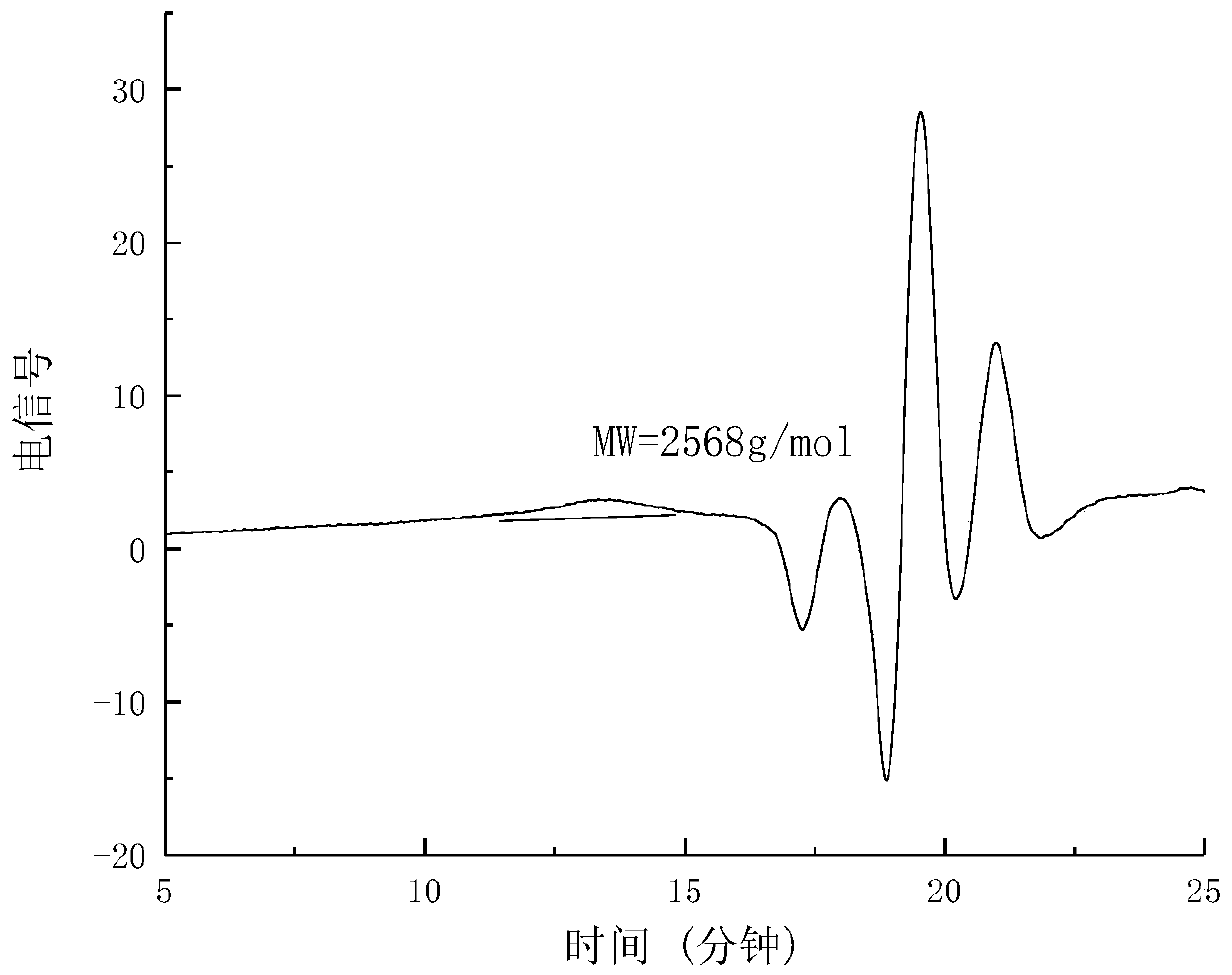

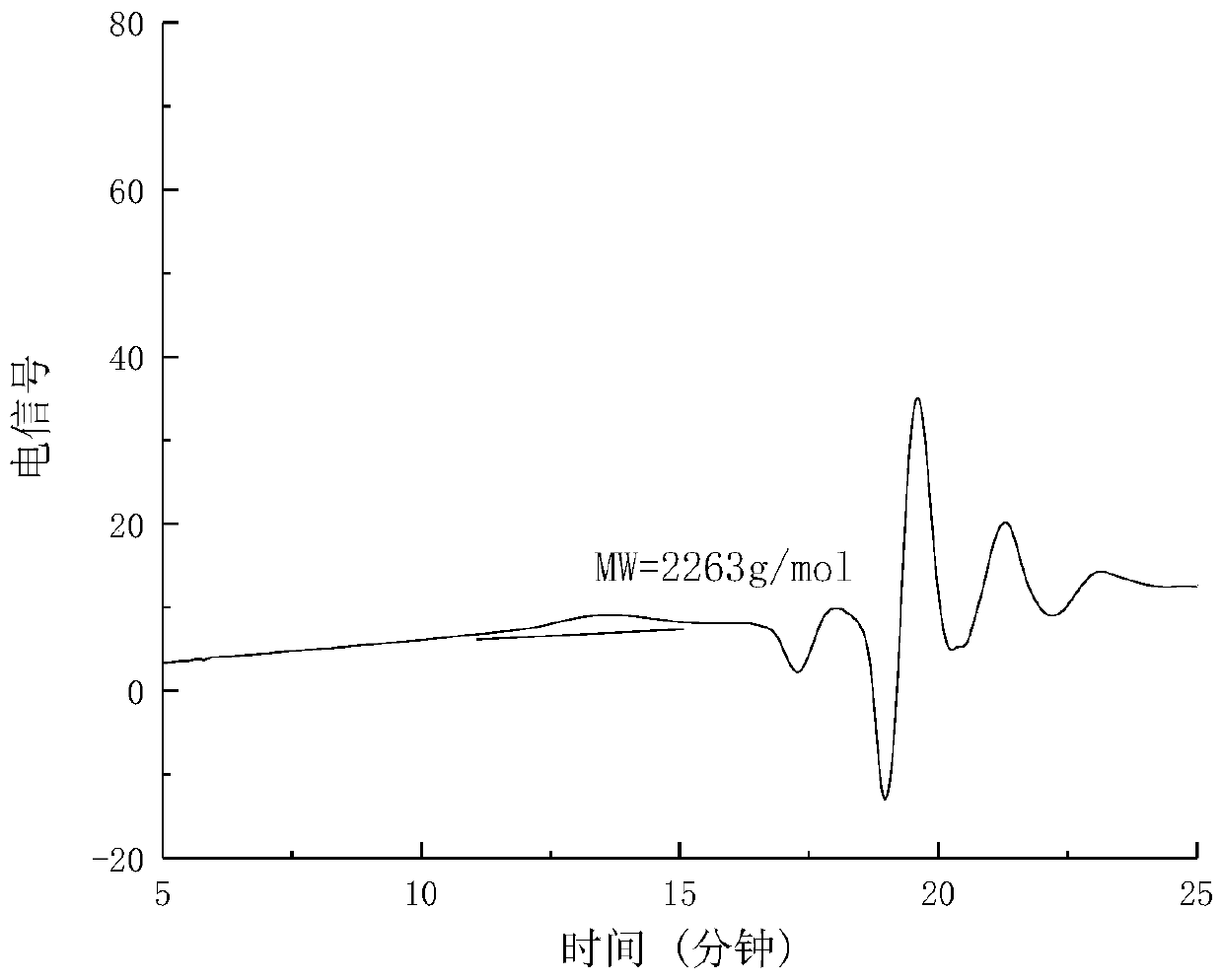

[0030] (2) At room temperature, add 2mol / L sulfuric acid to the diluent under stirring condition, adjust the pH value of the diluent to 6 and precipitate precipitates, continue stirring at room temperature for 30min, stirring speed 500rpm, centrifuge after stirring (3000r / min , 15min) to obtain the primary precipitate and the primary supernatant; continue to add 2mol / L sulfuric acid to the primary supernatant under stirring conditions, adjust the pH value to 4 and precipitate the precipitate at the same time, and obtain the secondary precipitate and Secondary supernatant; continue to add 2mol / L sulfuric acid to the secondary supernatant under stirring conditions, adjust the liquid pH value to 2 and precipitate precipitates at the same time, and obtain third-grade precipitates and third-grade supernatants t...

Embodiment 2

[0037] (1) Take 100ml of the above black liquor sample, filter it with filter paper to remove the solid impurities in it, add 800ml of distilled water to dilute to obtain the diluent;

[0038] (2) At room temperature, add 3mol / L sulfuric acid to the diluent under stirring condition, adjust the pH value of the diluent to 6 and precipitate precipitates at the same time, continue stirring at room temperature for 30min at a stirring speed of 500rpm, centrifuge after the stirring is completed (4000r / min , 10min) to obtain the primary precipitate and the primary supernatant; continue to add 3mol / L sulfuric acid to the primary supernatant under stirring conditions, adjust the pH value to 4 and precipitate the precipitate at the same time, and obtain the secondary precipitate and Secondary supernatant; continue to add 3mol / L sulfuric acid to the secondary supernatant under stirring conditions, adjust the liquid pH value to 2 and precipitate precipitates at the same time, and obtain ter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com