A printing machine automatic ink filling device

An automatic ink filling and printing machine technology, applied in printing machines, printing, general parts of printing machinery, etc., can solve the problems of low efficiency, waste of resources, waste of ink, etc., and achieve convenient use, energy saving, and energy consumption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

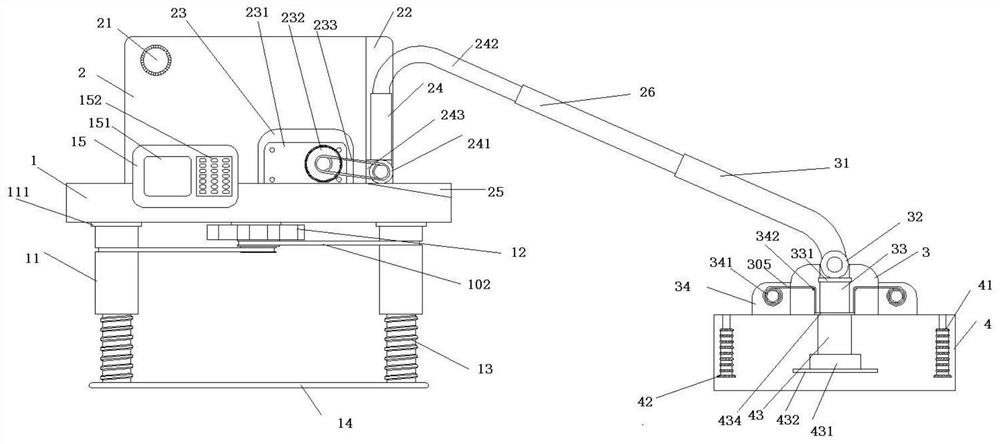

[0028] An automatic ink filling device for a printing machine, comprising a base 1, an ink tank 2 and an ink cartridge 4, the upper end of the base 1 is fixed with an ink tank 2, the ink tank 2 and the ink box 4 are connected by a pipeline, and the base 1 is used For fixing the ink tank 2 and adjusting the height of the ink tank 2, the ink tank 4 is installed in the printing machine to provide ink required for printing by the printing machine, and the ink tank 2 is used to add ink to the ink tank 4 when the ink tank 4 has no ink;

[0029] The upper end of the base 1 is provided with a console 15, the lower end of the base 1 is provided with a rotating column 11 on both sides, the right side of the base 1 is provided with a ramp 25, the lower end of the rotating column 11 is threadedly connected with the threaded column 13, and the bottom of the threaded column 13 passes through the support 14 are connected, the upper end of the base 1 is fixedly provided with an ink tank 2, the...

Embodiment 2

[0031] The difference between this embodiment and Embodiment 1 is that the lower end of the base 1 is provided with a runner 12, and the runner 12 and the swivel column 11 rotate synchronously through the connection of the crawler belt 102, and the runner 12 is connected to the base 1 through the rotation shaft 111 at the upper end. , the rotating column 11 is rotationally connected with the base 1 through the rotating shaft 111, and the directions of the two threaded columns 13 are the same.

Embodiment 3

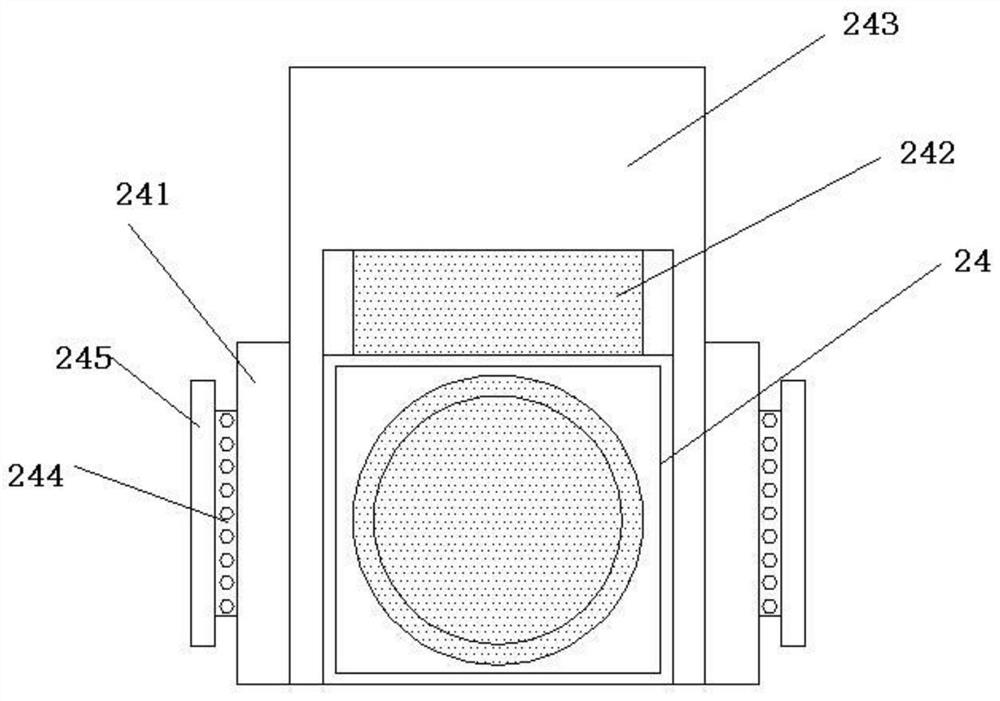

[0033] The difference between this embodiment and embodiment 1 is that, as figure 2 as shown, figure 2 It is a bottom view of the ink-filling tube of the present invention. The upper end of the ink-filling tube 243 is provided with a gap, and the bottom of the rotary tube 24 is stuck in the gap of the ink-filling tube 243. It is rotatably connected with the ink supply tube 243, and the ink supply tube 243 gap is provided with an ink delivery hose 242, and a section of the ink delivery hose 242 is connected to the inside of the ink tank 2, and the other end of the ink delivery hose passes through the inside of the coil 24 to extend out and connect with the ink tank 2. Ink delivery slide pipe 26 is connected.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com