Preparation method for SFCB (Steel-Fibre Composites Bar)

A steel bar and prefabricated technology, applied in the field of SFCB bar preparation, can solve the problem of insufficient bonding force between the inner core steel bar and the outer composite material, affecting the synergistic force between the inner core steel bar and the outer composite material, and failing to achieve the effect of use, etc. problem, to achieve the effect of good bonding effect, good alkali corrosion resistance and good overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

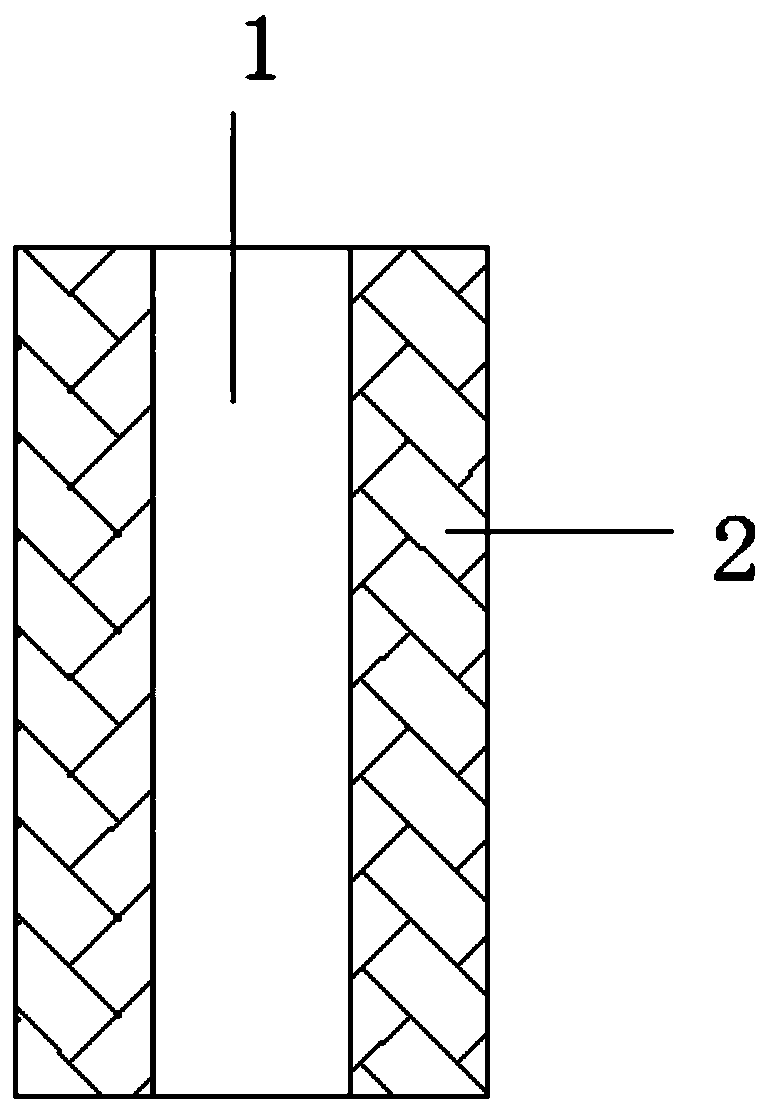

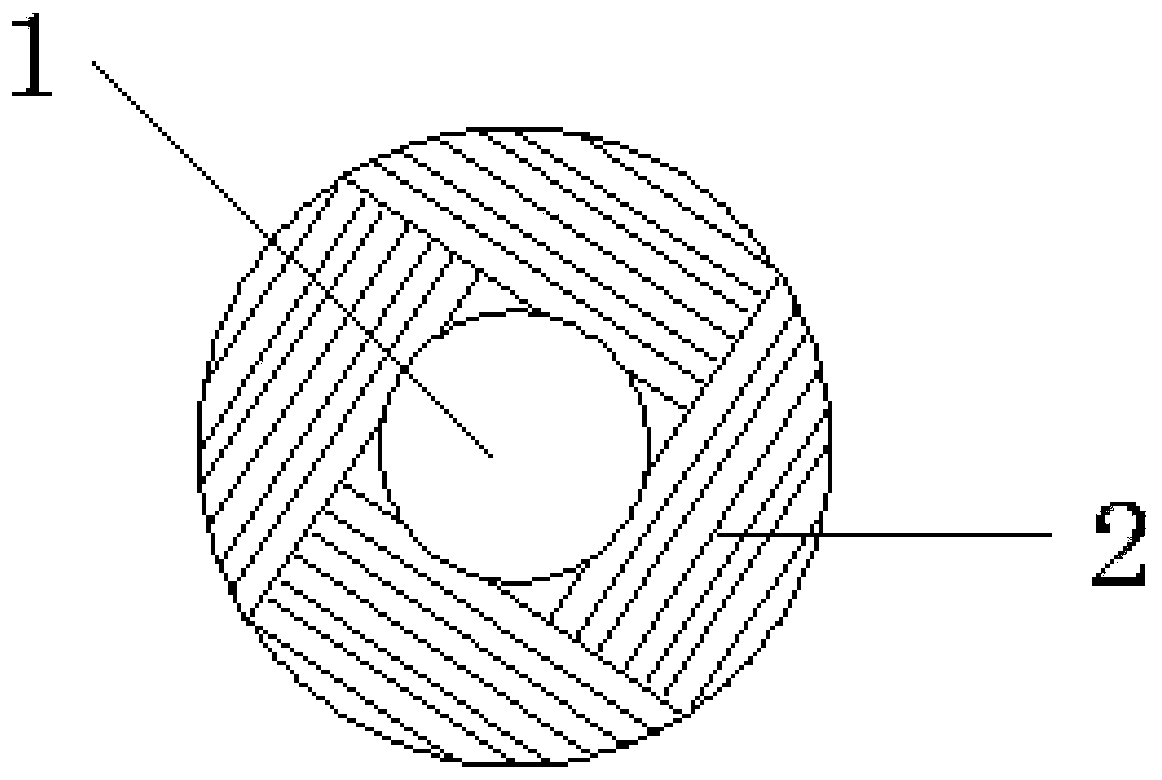

[0025] (1) Choose a smooth round bar with a diameter of 8mm as the inner core steel bar 1. The three-dimensional weaving machine circular weaving process is adopted, and the two-step method is adopted. The inner core steel bar 1 is used as the axial fixed unit, and the basalt fiber moves around the steel bar to weave the SFCB bar prefabricated body. Wherein, the cross-sectional area of the fiber 2 should not be smaller than the cross-sectional area of the inner core steel bar (1).

[0026] (2) Evenly coat a layer of release agent on the molding mold, impregnate the SFCB prefabricated body with bisphenol A epoxy resin, put it into the molding mold, and heat up to 80°C for 30 minutes; then raise the temperature to 160°C, pressurize To 10Mpa, hold for 60s, solidify and shape.

[0027] The SFCB bars prepared in this example have a strength of 730 MPa and a secondary stiffness of 51 GPa. In the alkaline solution prepared by ACI440.3R, placed at 60°C for 1 month, the residual ...

Embodiment 2

[0029] (1) Select the deep rib bar with an inner diameter of 8mm as the inner core steel bar 1. The steel bar is wound with carbon fiber, so that the space between the ribs is filled and the surface of the ribbed bar is smooth. The circular weaving process of the three-dimensional braiding machine is adopted, and the four-step method is adopted. The inner core steel bar 1 is used as the axial fixed unit, and the carbon fiber moves around the steel bar in an interlaced manner to weave into a three-dimensional five-directional SFCB bar prefabricated body. Wherein, the cross-sectional area of the fiber 2 should not be smaller than the cross-sectional area of the inner core steel bar 1 .

[0030] (2) Apply a layer of release agent evenly inside the mold, put the SFCB tendon prefabricated body into it, spread the diversion net, seal the vacuum bag and evacuate it, raise the temperature to 120°C, and inject vinyl resin into it , followed by curing at 180°C for 2 hours.

[0031...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com