Special device for replacing broach spring and using method thereof

A special device, the technology of spring pressing sheet, applied in the accessories, positioning device, broaching machine and other directions of the broaching machine, can solve the problems of easy damage, difficult replacement of broach springs, high cost, and achieve the effect of reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

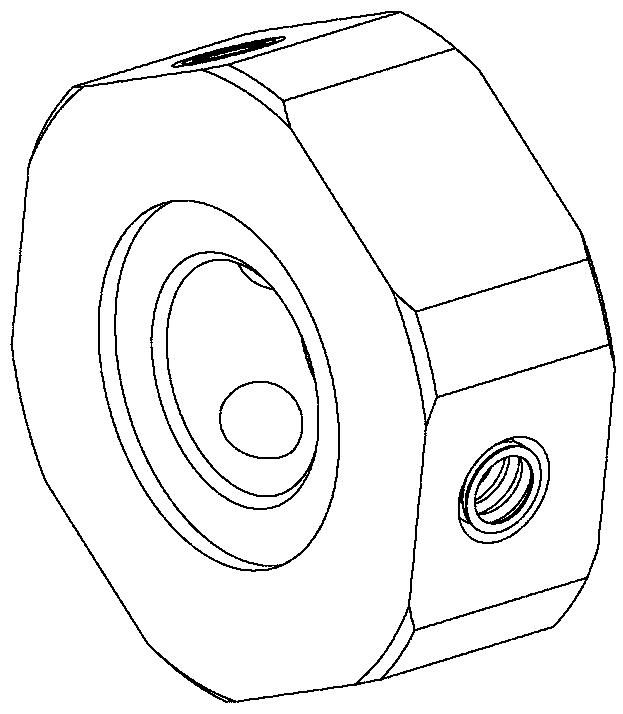

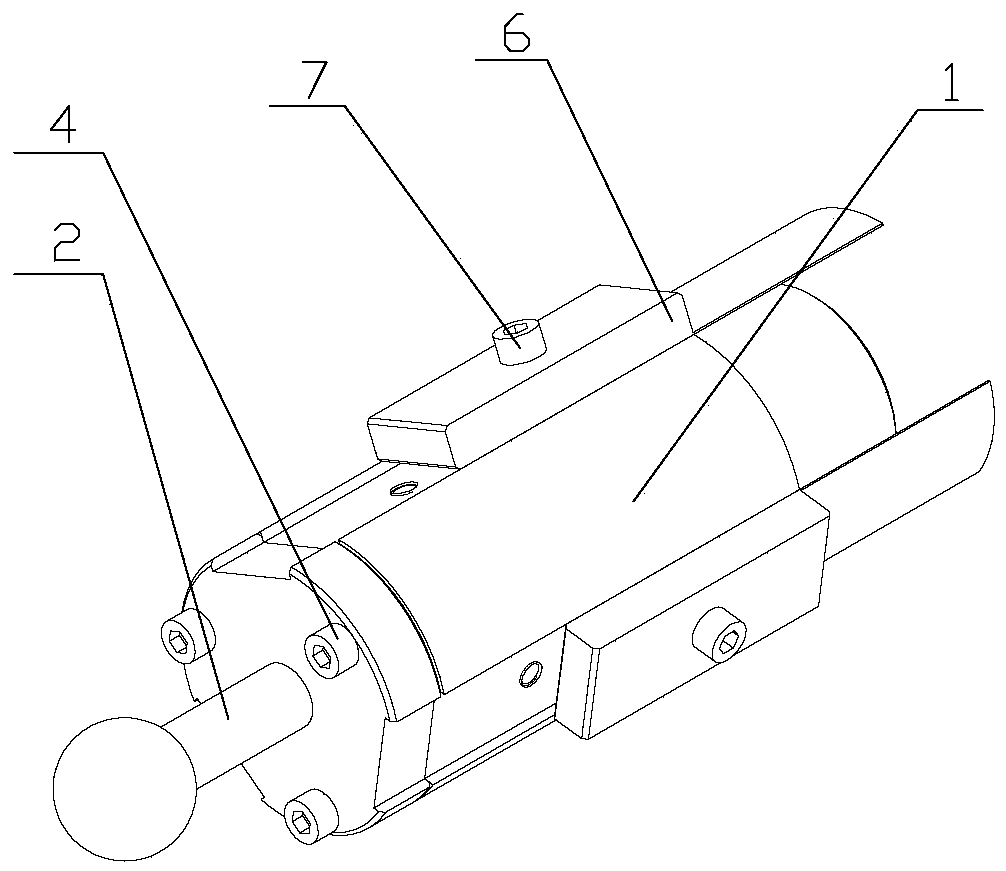

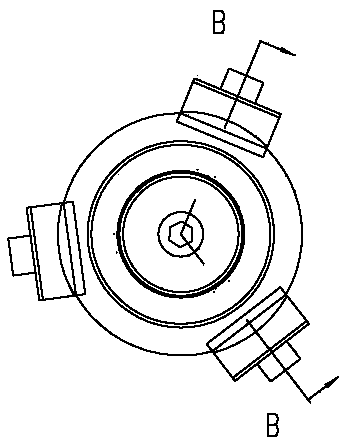

[0023] See Figure 2 to Figure 5 As shown, a special device for replacing the broach spring, which includes a cylinder body 1, and a connecting rod 2 that penetrates the cylinder body 1 is slidably installed. In the figure, 3 is the end cover, and 4 is the first screw for fixing the end cover and the cylinder body. , one end of the connecting rod 2 is equipped with a push plate 5, the cylinder 1 is open at this end, and the outer wall of the cylinder 1 is provided with three spring pressure pieces 6, which are located on the side of the push plate 5, and the ends of the spring pressure pieces 6 exceed the end of the cylinder 1 .

[0024] The outer wall of cylinder body 1 is provided with three threaded holes correspondingly, and the spring pressing plate 6 is mounted on the outer wall of cylinder body 1 through bolts 7 and threaded holes; the push plate 5 is fixed on the connecting rod 2 through the second screw 8; the other end of the connecting rod 2 is installed with The h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com