Roll cloth loading conveyor

A technology for conveyors and cloth rolls, which is applied in the direction of conveyors, loading/unloading, transportation and packaging, etc., which can solve the problems of long axial length, messy and irregular rolls, and no protective measures for the rolls, so as to achieve the goal of conveying high efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

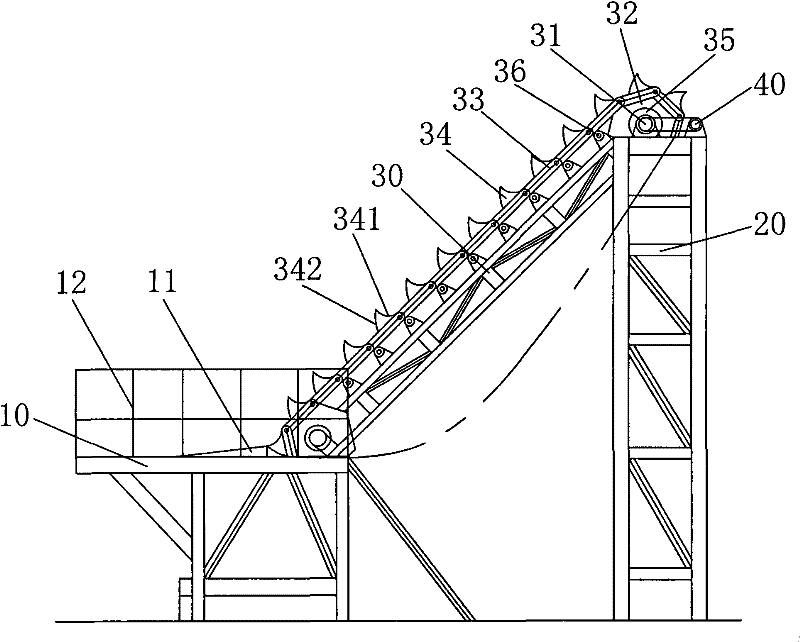

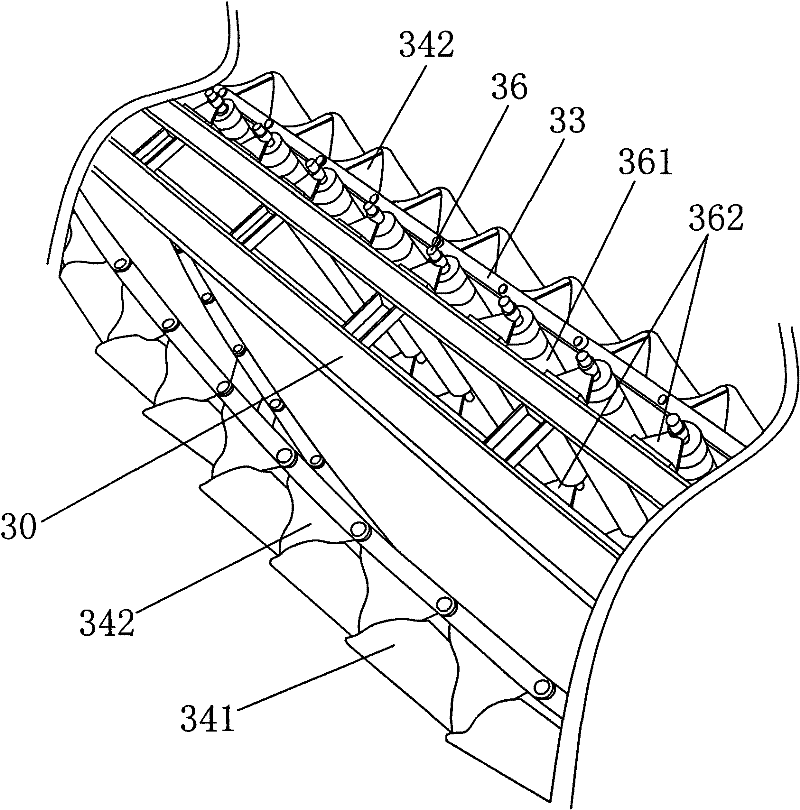

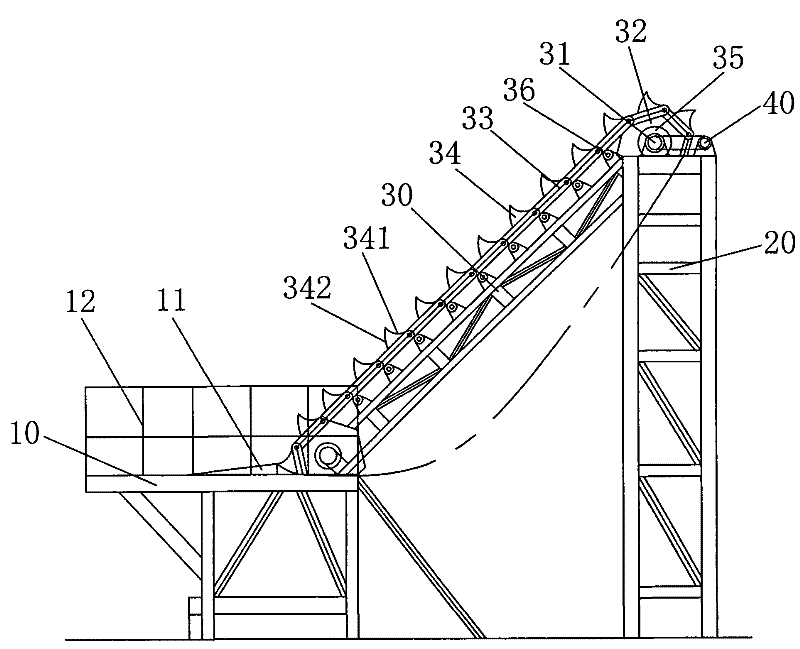

[0018] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see Figure 1-2 :

[0019] The packaged cloth loading conveyor is vertically provided with a front bracket 10 and a rear bracket 20, and an oblique bracket 30 is connected between the upper ends of the front and rear brackets 10, 20, and the upper end of the rear bracket 20 and the lower end of the oblique bracket 30 Transmission shaft 31 is respectively provided with, and the two ends of transmission shaft 31 are respectively provided with sprocket wheel 32, and the sprocket wheel 32 of transmission shaft 31 same side is suspended with endless chain 33 respectively, and is parallel to the outer surface of the endless chain 33 of transmission shaft 31 The upper interval is hinged with a material plate 34, and the transmission shaft 31 on the rear support 20 is coaxially provided with a driving wheel 35, and the driving wheel 35 is driven by a motor 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com