Hydraulic pneumatic pipe joint blank group die forging manufacturing method

A manufacturing method, hydropneumatic technology, applied in the direction of manufacturing tools, forging/pressing/hammering machinery, engine components, etc., can solve the problems of difficult to reduce product costs, high energy consumption, low output, etc., to reduce production costs, reduce Effects of energy consumption and productivity improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

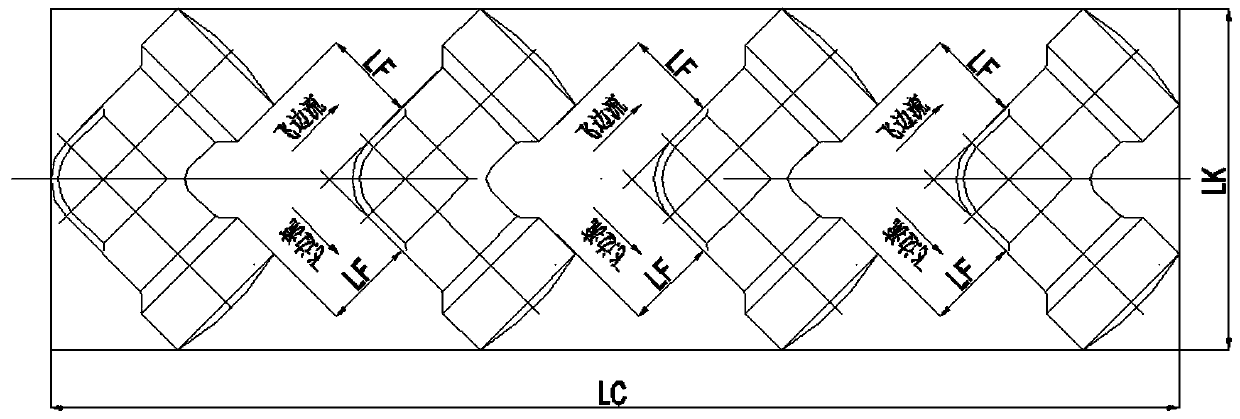

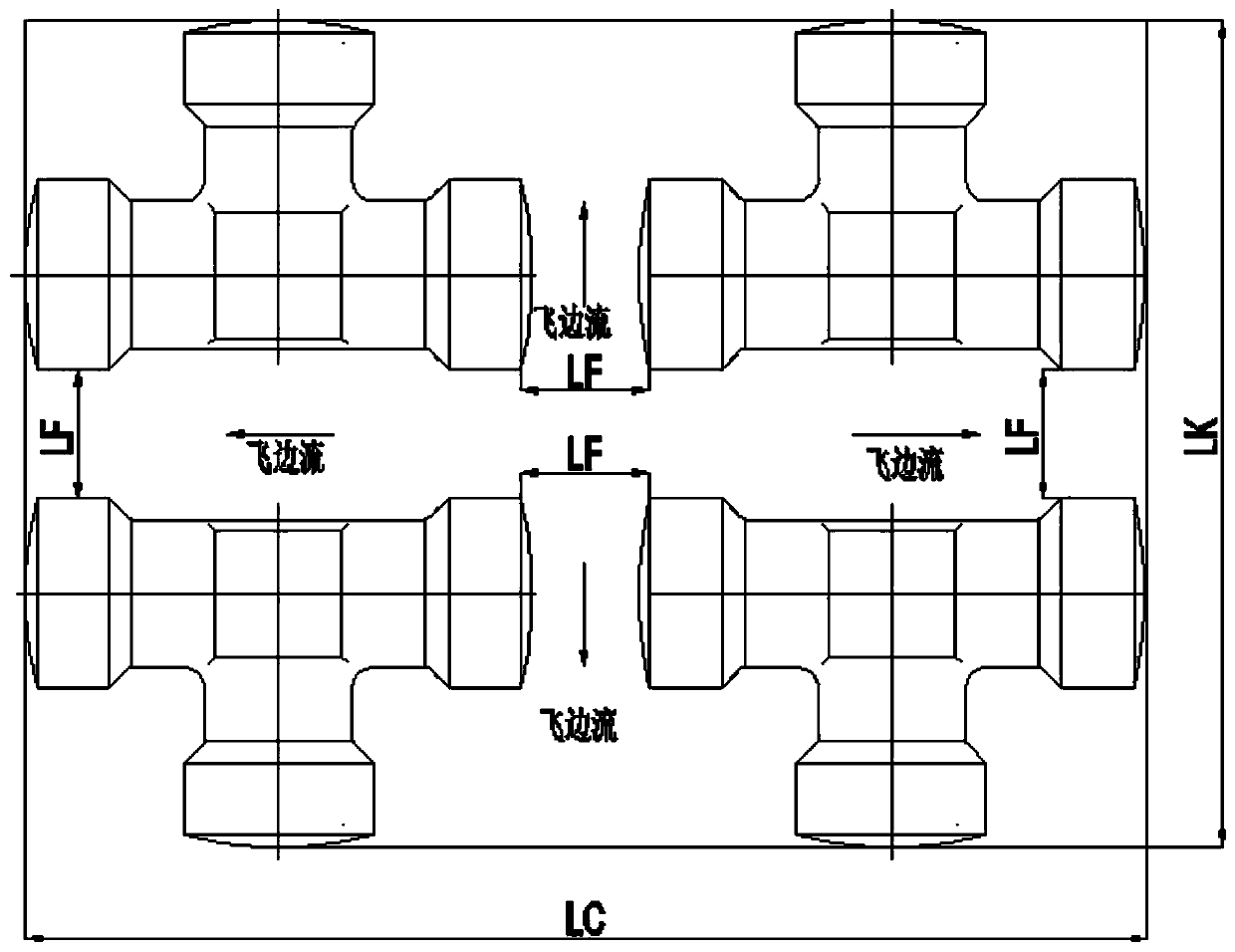

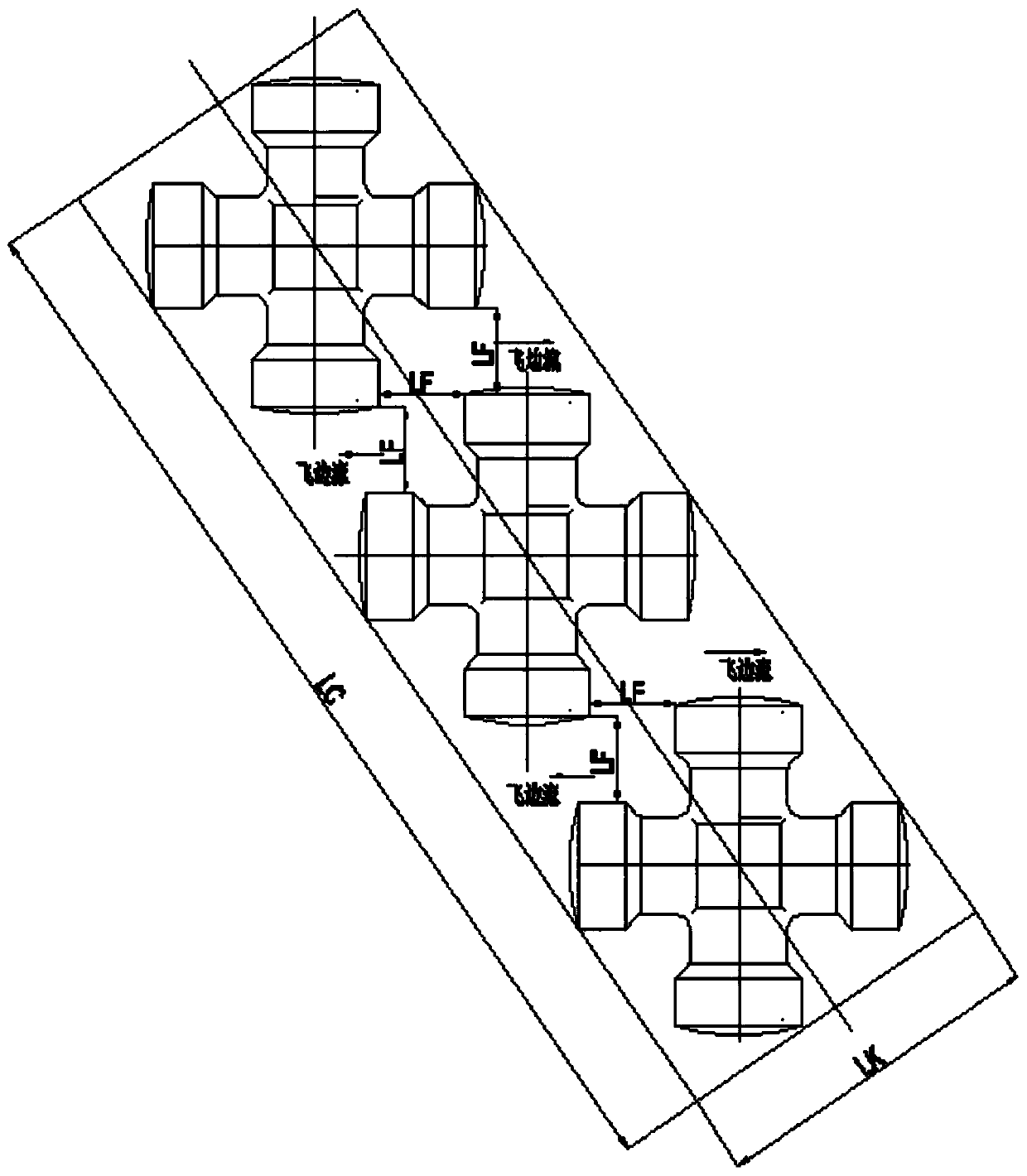

[0025] refer to Figure 1 to Figure 9 The invention discloses a group die forging manufacturing method for hydraulic and pneumatic pipe joint blanks. The group die forging manufacturing method manufactures pipe joint blanks based on the combined method of one die and multiple pieces, and the head or neck of the pipe joint blanks is absolutely symmetrical. , or cross-face symmetry, the form of each forging in the multi-piece mold is consistent, and the specific form includes: a combination of bends and bends, a combination of three-way and three-way, a combination of four-way and four-way;

[0026] The mold design of the group die forging manufacturing method is designed for the flow direction of the flash: the calculated value of the size of the flash flow LF is: LF=K(H+d1+d2) / 3; when d1=d2, LF=K( H+2d2) / 3; among them, the flash flow LF is the flash flow direction, H is the wrench size of the joint body, d1 is the diameter length of the blank head of the pipe joint, d2 is the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com