Method for preparing quartz glass microchannel core plate

A technology of quartz glass and microchannels, applied in chemical instruments and methods, chemical/physical/physicochemical processes, chemical/physical processes, etc., can solve problems such as time-consuming, mechanical load stress concentration, leakage, etc., and achieve high durability Effects of heat and light transmittance, simple process, and accelerated reaction speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

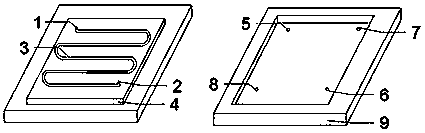

[0015] Now combined with figure 1 To further describe the specific technical solutions of the present invention, so that those skilled in the art can further understand the present invention, without restricting their rights.

[0016] (1) Prepare the boss quartz glass substrate by machining, as shown in 4 in the attached drawing;

[0017] (2) Choose a quartz glass capillary with an inner diameter of 0.5mm and an outer diameter of 2mm, and formulate a specific microchannel direction, as shown in the "Zigzag" direction shown in 3 in the attached drawing. The quartz glass capillary is welded to the convex by hot-melt technology. Table surface

[0018] (3) Use a notching machine to cut the grooves to prepare the grooved quartz glass plate substrate, as shown in Figure 9, the groove depth is greater than the sum of the height of the boss and the outer diameter of the quartz capillary, and the difference between the two is 2mm; Use a drilling machine to make 4 through holes, such as 5, 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com