BAR structure capable of increasing placement quantity

A technology of quantity and chip structure, applied in the field of laser BAR bars, can solve problems such as easy damage and contamination, small number of BAR bars, affecting quality, etc., to improve the yield rate and production efficiency, and solve the problem of insufficient coating capacity. , The effect of low processing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

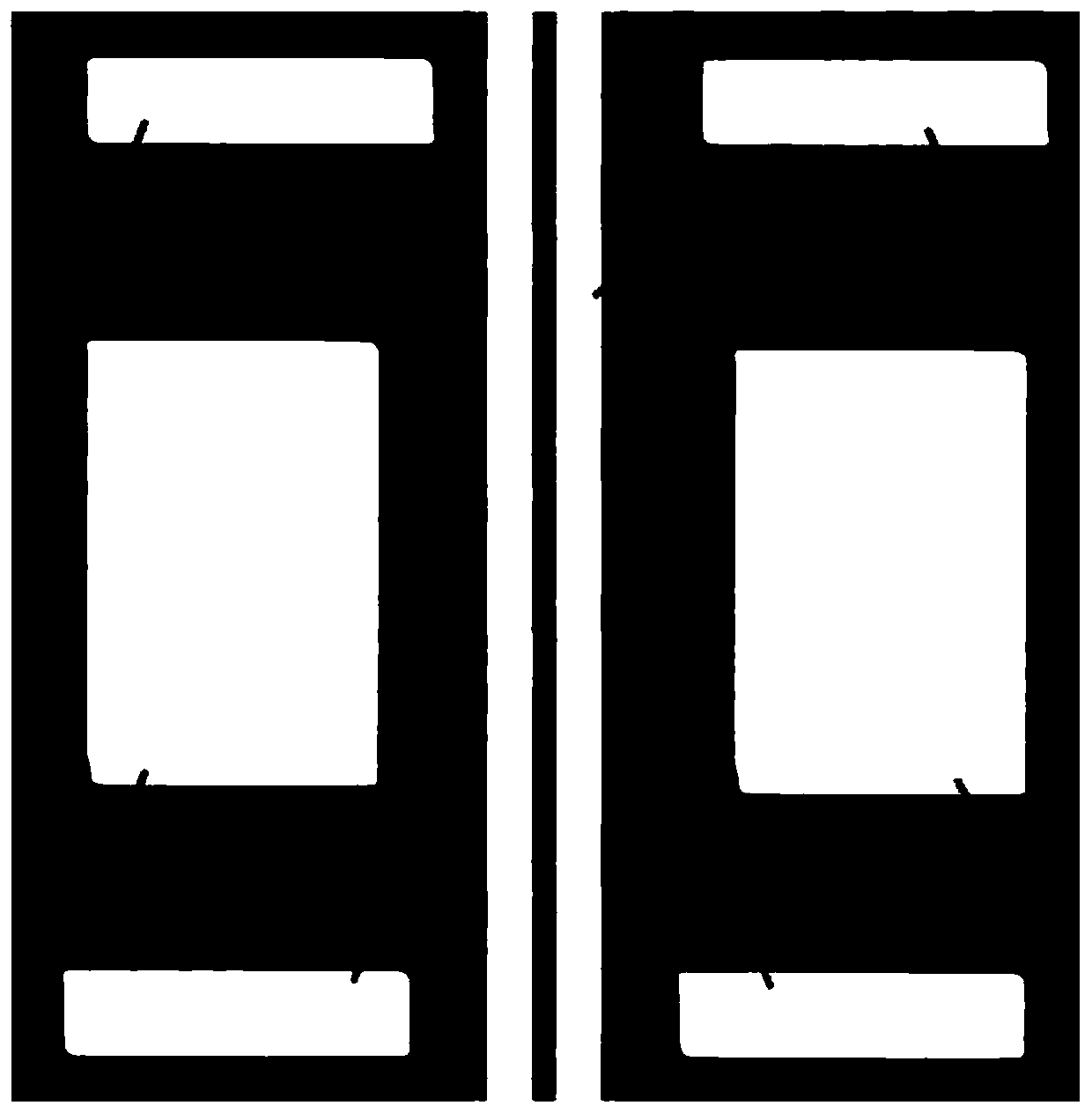

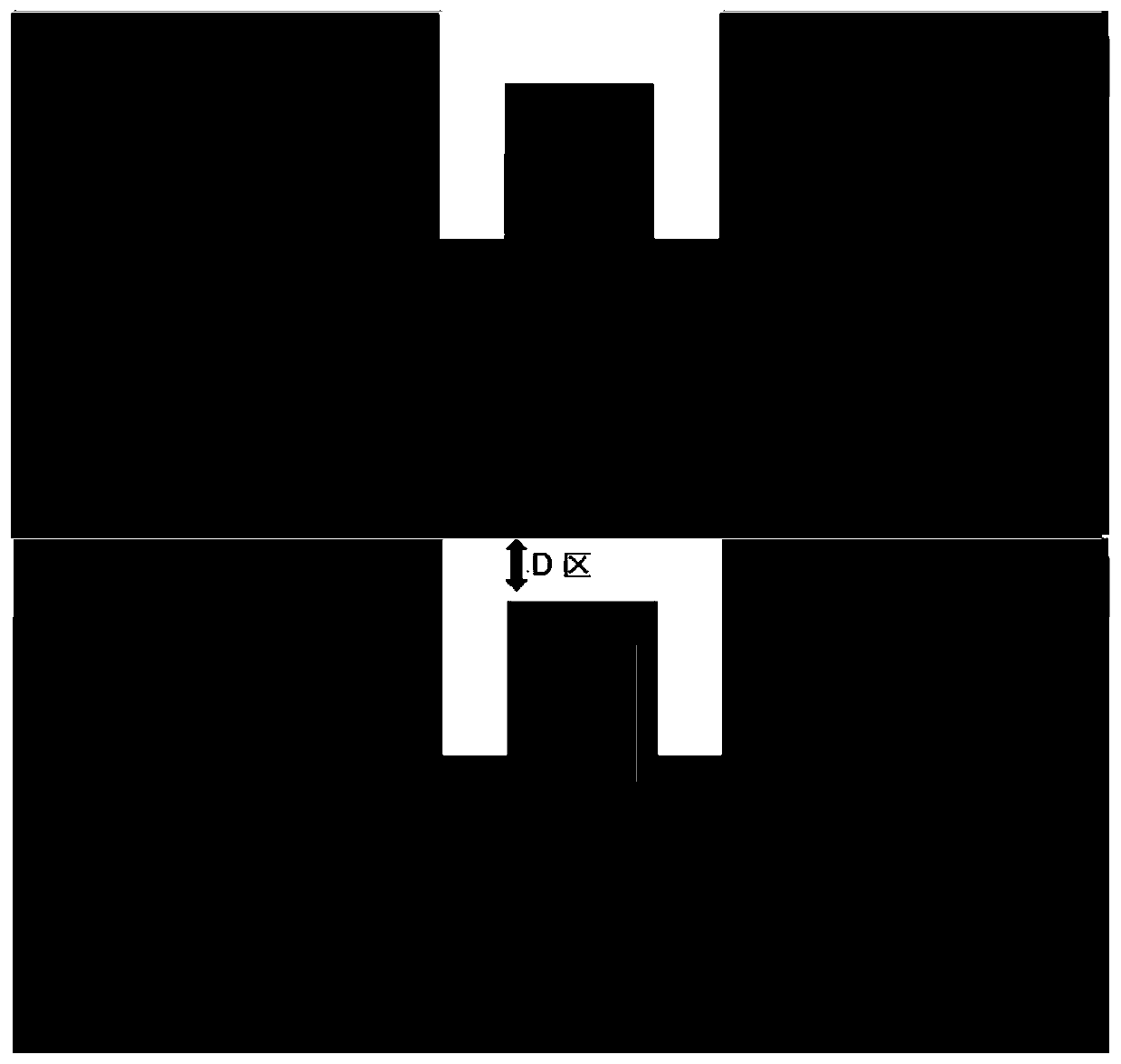

[0020] Example: as figure 1 ~ figure 2 As shown, a BAR bar structure that can increase the number of placements is formed. The BAR bar is connected by several chip structures. The middle part of the chip structure is provided with a long strip-shaped ridge area, and the two ends of the ridge area respectively extend to the Edges at both ends of the chip structure; the chip structure on both sides of the ridge region is provided with a first metal region, the two first metal regions are symmetrically arranged with respect to the ridge region, and a second metal region is arranged on one side of the first metal region , the two second metal regions are respectively arranged symmetrically on both sides of the ridge stripe region; the heights of the first metal region and the second metal region are both greater than the height of the ridge stripe region. The ridge area includes a raised ridge in the middle and grooves on both sides, and the upper layer of the ridge area is pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com